Tube-plate contact type fretting wear clamp of high-temperature high-pressure water and using method

A high temperature and high pressure, fretting wear technology, applied in the field of processing fixtures, can solve the problem of difficulty in ensuring the tightness and parallelism of friction pairs at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

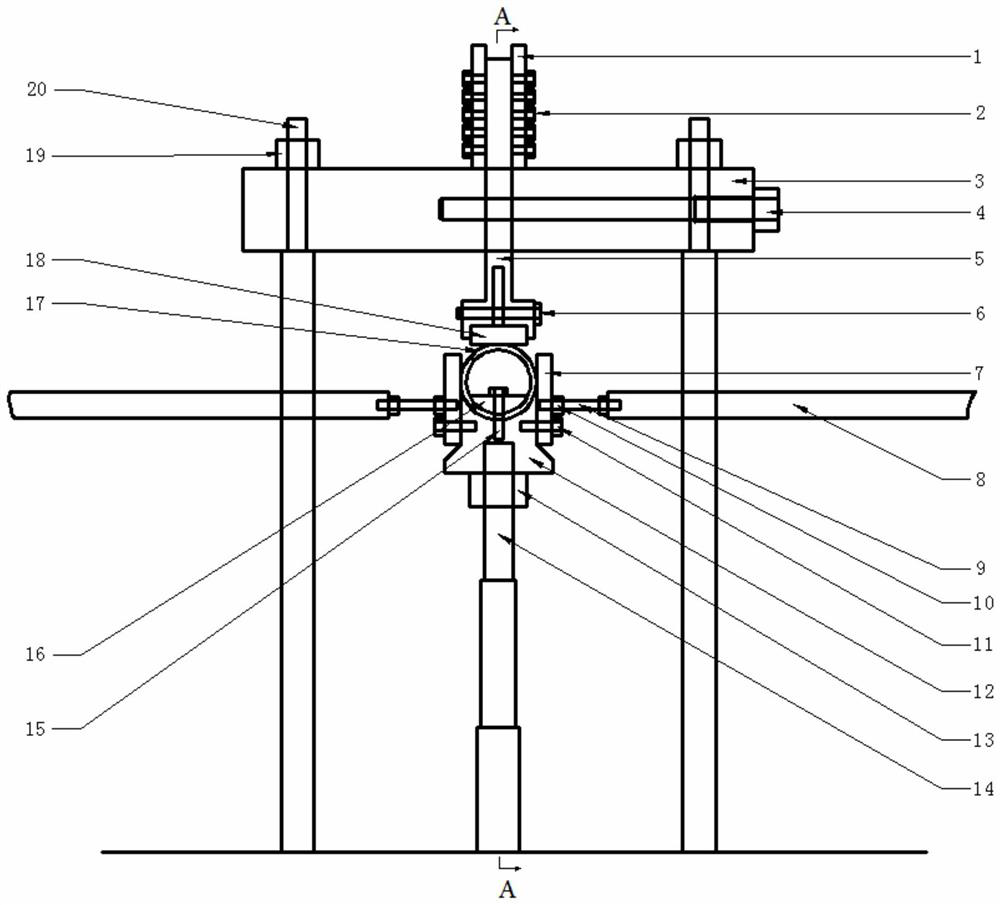

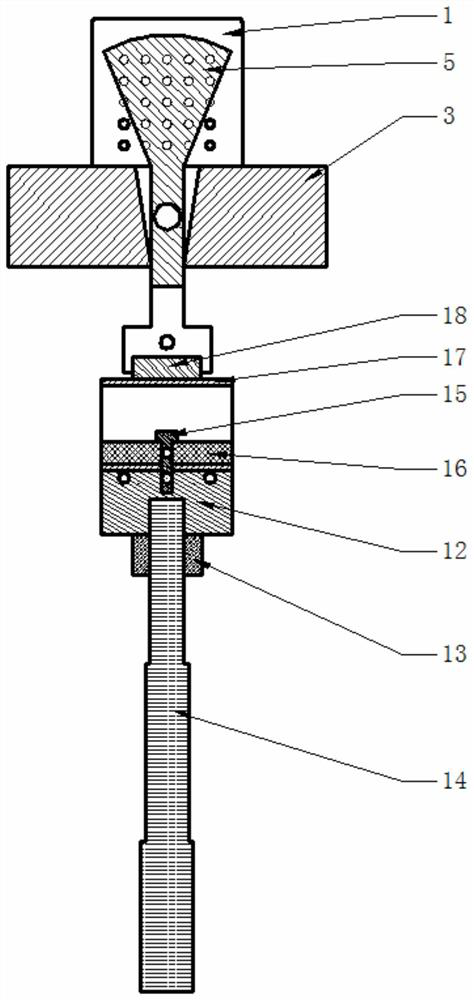

Method used

Image

Examples

Embodiment

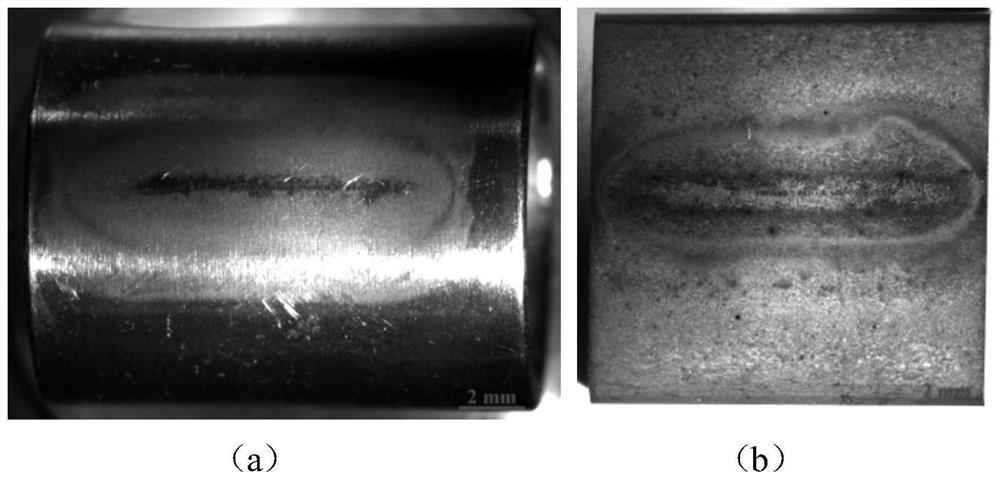

[0053] In the embodiment, the outer diameter of the 690 alloy steam generator heat transfer tube (tubular sample) used is 19.05 mm, the wall thickness is 1.09 mm, and the length is 15 mm; the anti-vibration strip (plate sample) used is 405 Stainless steel, the sample size is 12mm×12mm×4mm. After the sample is installed according to the above method of use, the fretting wear test is carried out in high temperature and high pressure water. The test temperature is 288°C, the pressure is 9MPa, the normal load is 60N, the vibration frequency is 60Hz, the amplitude is ±50μm, and the test time is 50h . Such as image 3 As shown, after the test is completed, the appearance of the wear marks on the heat transfer tube and the anti-vibration strip shows that the width of the wear marks is uniform and linear, indicating that the parallel state of the sample is good when it is installed, which meets the test and design requirements.

[0054] The results of the examples show that the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com