Mobile phone shell spraying-free injection molding method adopting mechanical mold inner cutting

A mobile phone case, in-mold cutting technology, applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of smooth surface easily scratched, lack of heat resistance of mobile phone case, poor heat resistance of mobile phone case, etc. Achieve the effects of reducing the probability of being scratched, good toughness, and good color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

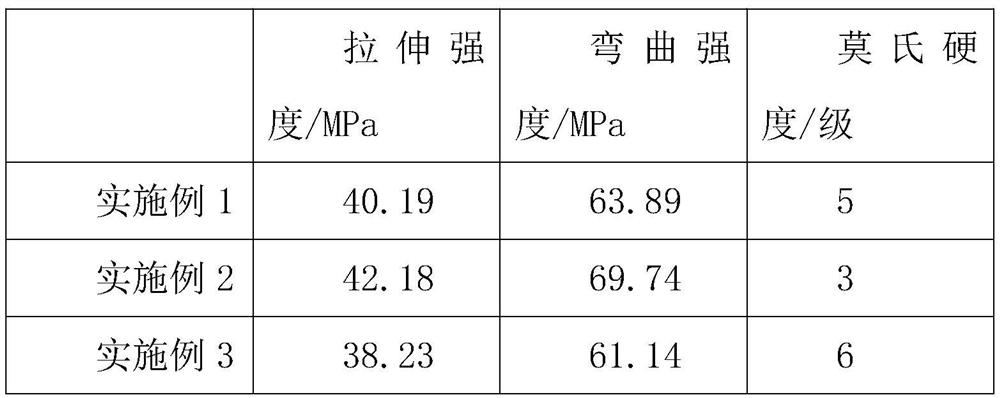

Embodiment 1

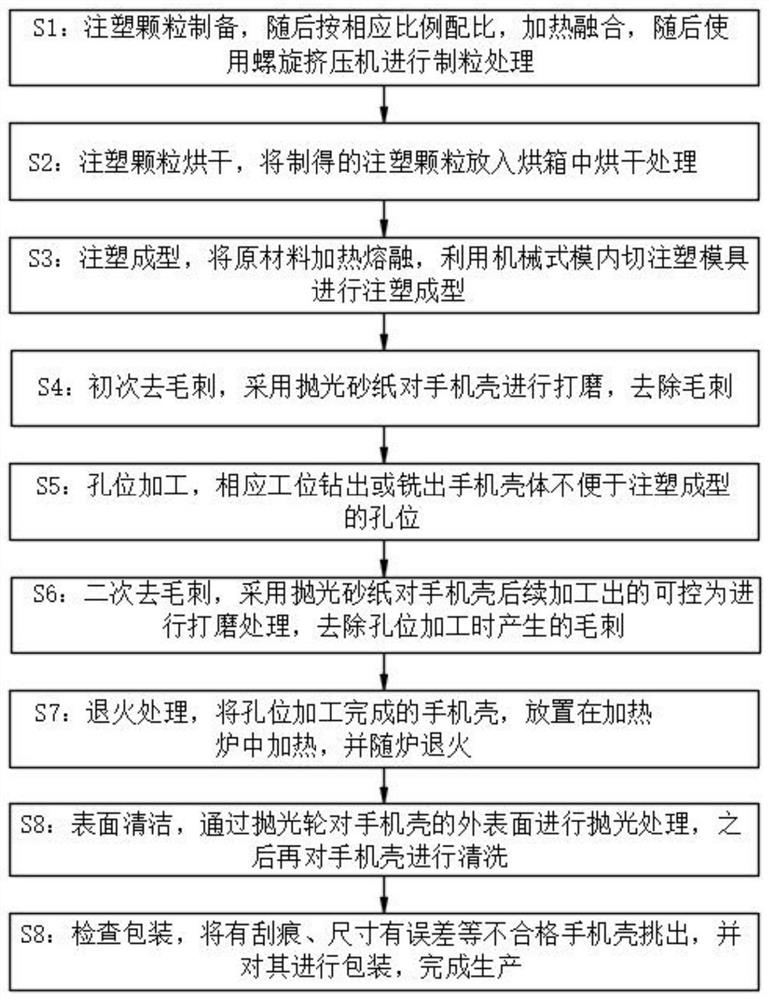

[0027] A spray-free injection molding method for a mobile phone case with mechanical in-mold cutting, comprising the following steps:

[0028] Step (1), preparation of injection molding particles, the raw material is prepared by the following elemental components by weight percentage, including 2.2% aluminum powder, 0.04% carbon black, 0.15% antioxidant, 0.15% dispersant and 0.8% high-gloss toner , hardness modifier 8%, the rest is ABS plastic raw material, the weight percentage sum of each component is 100%, then according to the corresponding ratio, each material is heated and fused, and then the fused material is processed by a screw extruder Carry out granulation treatment to form injection molding granules for use;

[0029] Step (2), drying of the injection molding granules, put the prepared injection molding granules into an oven for drying treatment, set the drying temperature at 70°C to 85°C, dry for 4-5 hours, and control the moisture in the injection molding granules...

Embodiment 2

[0044] A spray-free injection molding method for a mobile phone case with mechanical in-mold cutting, comprising the following steps:

[0045] Step (1), preparation of injection molding particles, the raw material is prepared by the following elemental components by weight percentage, including 1.5% aluminum powder, 0.04% carbon black, 0.15% antioxidant, 0.15% dispersant and 0.8% high-gloss toner , hardness modifier 5%, the rest is ABS plastic raw material, the weight percentage sum of each component is 100%, then according to the corresponding ratio, each material is heated and fused, and then the fused material is melted by a screw extruder Carry out granulation treatment to form injection molding granules for use;

[0046] Step (2), drying of the injection molding granules, put the prepared injection molding granules into an oven for drying treatment, set the drying temperature at 70°C to 85°C, dry for 4-5 hours, and control the moisture in the injection molding granules at...

Embodiment 3

[0061] A spray-free injection molding method for a mobile phone case with mechanical in-mold cutting, comprising the following steps:

[0062] Step (1), preparation of injection molding granules, the raw material is prepared by the following elemental components by weight percentage, including 2.5% aluminum powder, 0.04% carbon black, 0.15% antioxidant, 0.15% dispersant and 0.8% high-gloss toner , hardness modifier 10%, the rest is ABS plastic raw material, the weight percentage sum of each component is 100%, then according to the corresponding ratio, each material is heated and fused, and then the fused material is melted by a screw extruder Carry out granulation treatment to form injection molding granules for use;

[0063] Step (2), drying of the injection molding granules, put the prepared injection molding granules into an oven for drying treatment, set the drying temperature at 70°C to 85°C, dry for 4-5 hours, and control the moisture in the injection molding granules at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com