A split nut type compression release device actuated by a hot knife

A split nut and release device technology, applied in the aerospace field, can solve the problems of non-repeatability, serious pollution, poor safety, etc., and achieve the effects of low manufacturing cost, less material and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

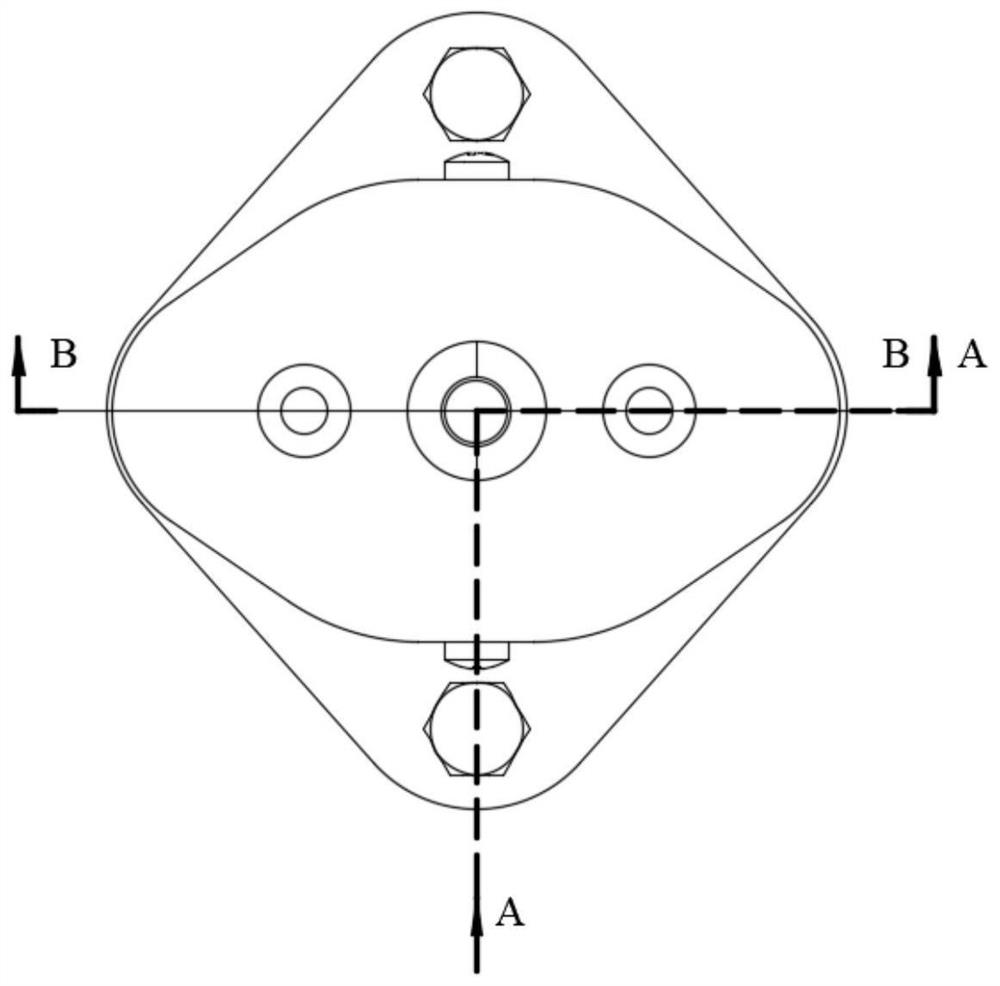

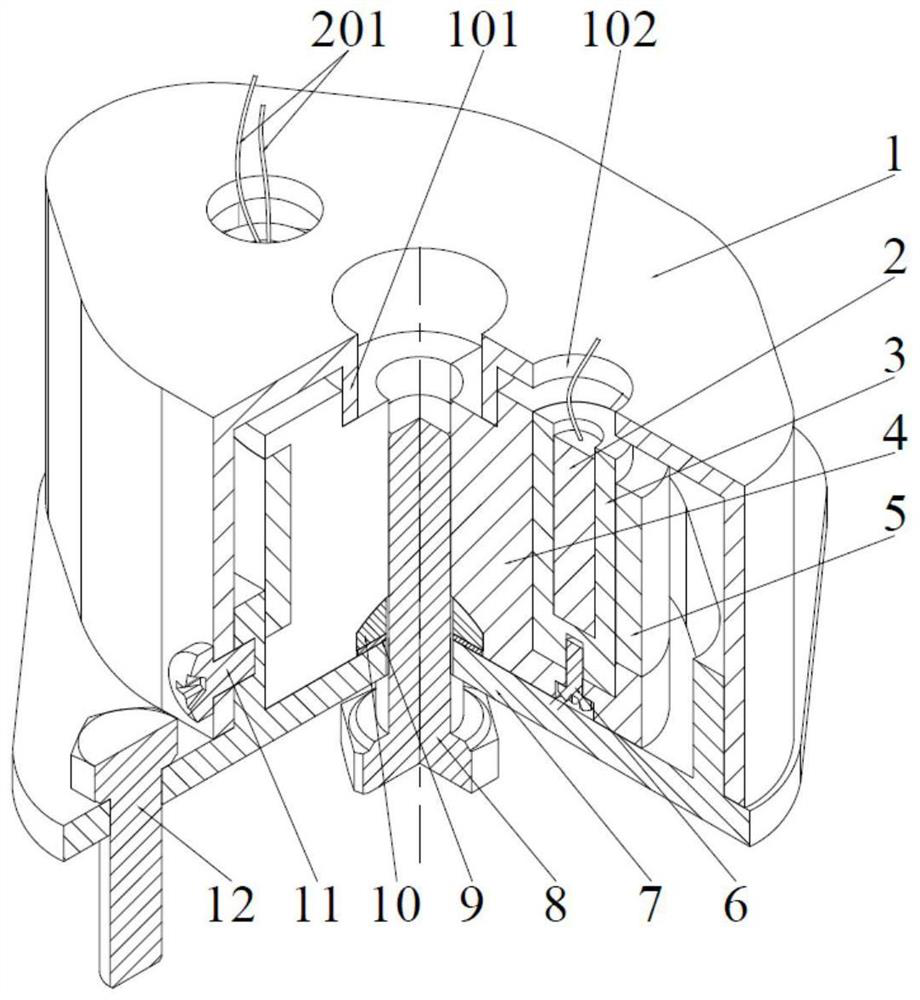

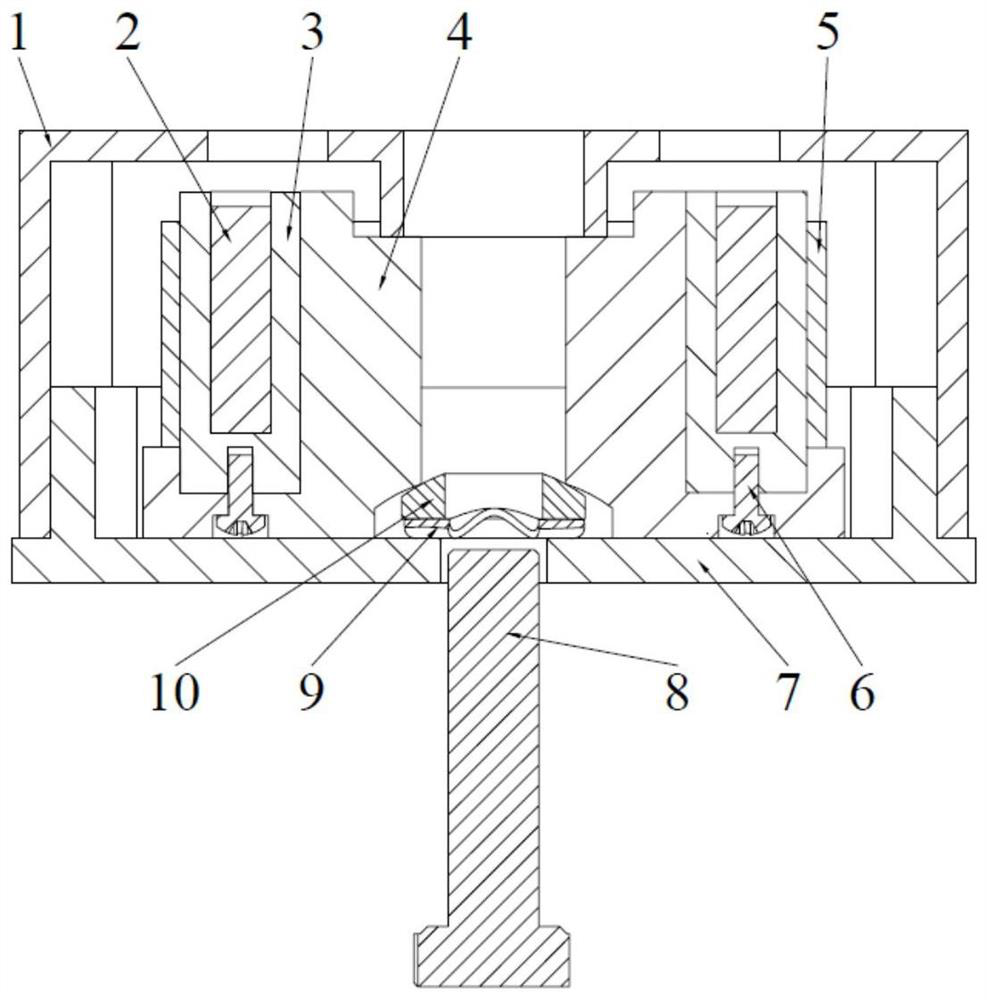

[0032] Such as Figure 1-Figure 5 As shown, a hot-knife-actuated split-nut type compression release device includes two hot knives 2, two heat-transfer sleeves 3, and two-lobe Type split nut 4, rope harness 5, bearing bolt 8, wave elastic washer 9 and spherical washer 10, described two-lobed split nut 4 is arranged at the center of the space surrounded by top cover 1 and base 7, The two nut sections of the two-petal split nut 4 are merged together to form a complete thread, and the two heat transfer sleeves 3 are symmetrically fixed on the two petals of the two-petal split nut 4, and a The hot knife 2, the rope harness 5 is wound on the outer surface of the two-lobed split nut 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com