Method for preparing lithium carbonate by using acid-resistant membrane

A lithium carbonate, acid-resistant film technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of long time, low concentration of lithium-containing solution, time-consuming and labor-intensive extraction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

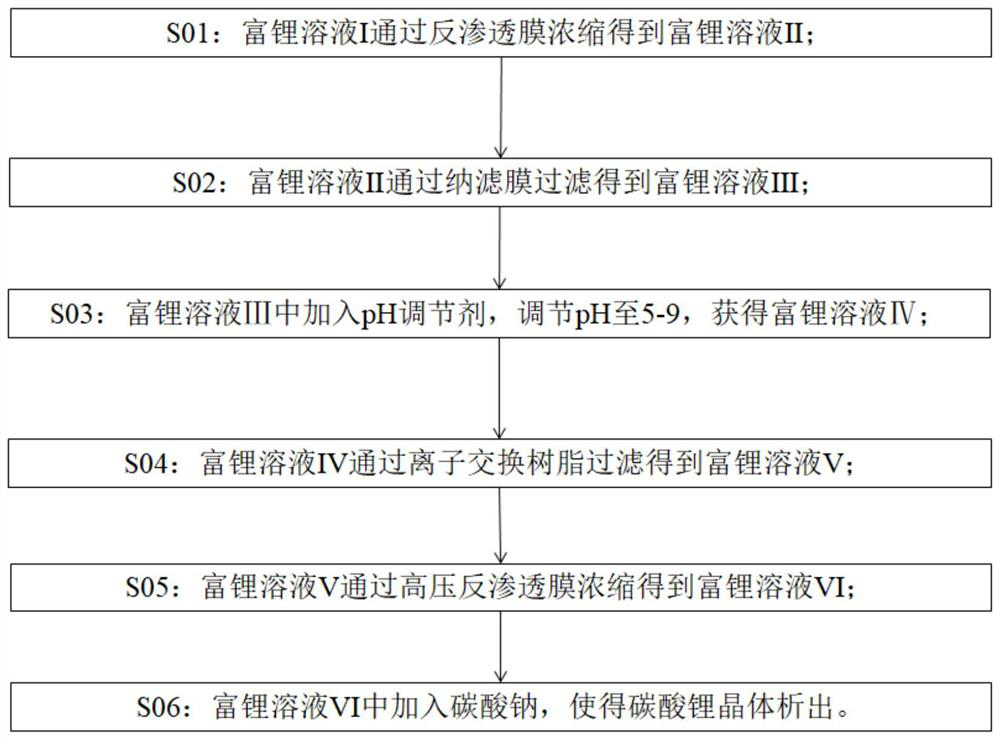

[0031] as attached figure 1 Shown, a kind of method that utilizes acid-resistant membrane to prepare lithium carbonate provided by the invention comprises the steps:

[0032] S01: Lithium-rich solution I is concentrated through reverse osmosis membrane to obtain lithium-rich solution II; wherein, the lithium concentration in lithium-rich solution I is 1-5g / L, and the lithium concentration in lithium-rich solution II is 2-10g / L. The reverse osmosis membrane is an acid-resistant reverse osmosis membrane, which can be used in the environment of pH 0.5-8. Specific reverse osmosis membrane suppliers include, but are not limited to, DuPont, SUEZ, Koch, etc.

[0033] S02: The lithium-rich solution II is filtered through the nanof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com