Circulating spinning device and application thereof in preparation of uniform nanofiber diaphragm

A technology of spinning device and driving device, which is applied in the field of circulating spinning device and its application in the preparation of uniform nanofiber diaphragm, which can solve the problems of large surface density and thickness deviation, inability to fully utilize the nanofiber diaphragm, and inability to move And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the method for preparing a nanofiber membrane with a uniform thickness in the present invention, a plurality of circulating spinning devices can be used for simultaneous spinning to prepare a fiber membrane, and the spinning needle points (nozzles) on each circulating spinning device can be at the same starting position , and can also be staggered at a certain distance to achieve better results.

[0028] In the present invention, the plurality of spray heads are fixedly installed on the transmission belt in an equidistant manner. In the present invention, the driving wheel is connected with a motor, and through the motor, the driving wheel, the driven wheel and the conveyor belt, the spray head mounted on the conveyor belt is driven to realize circular operation. Since the distance between each nozzle is the same, the nanofibers extruded by the nozzle evenly fall on the receiving device during the circular movement of the nozzle driven by the conveyor belt, which hel...

Embodiment 1

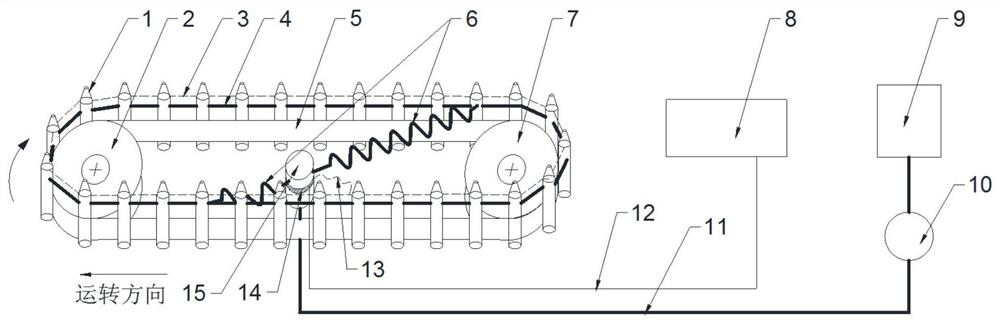

[0041] see figure 1 , this embodiment provides a method for preparing a nanofiber membrane of uniform thickness through a circulating spinning device, using several circulating spinning devices to prepare the nanofibers by electrospinning; the circulating spinning device includes a driving device, Liquid supply device, power supply device and spinning device; Described driving device comprises driving wheel 2, driven wheel 7 and conveyer belt 5, and described conveyer belt 5 is connected with it through described driving wheel 2 and driven wheel 7; Said liquid supply The device comprises a solution storage tank 9, a metering pump 10, a solution delivery pipeline 11 and a liquid separator 15, the solution storage tank 9 is connected with the liquid distributor 15 through the solution delivery pipeline 11, and the solution delivery pipeline 11 is The metering pump 10 is provided; the power supply device includes a high-voltage power supply 8, a high-voltage power supply line 12 ...

Embodiment 2

[0043] A method for preparing a nanofiber diaphragm of uniform thickness is provided, wherein 5 circulating spinning devices as shown in Example 1 are used to jointly prepare a nylon (PA) nanofiber diaphragm, and its specific method includes the following steps:

[0044] 1. Add the PA solution into the solution tank, turn on the gear pump, and the flow rate of the gear pump is 5ml / min. After the PA solution fills the dispenser, turn on the high voltage power supply and set the voltage to +70±5KV.

[0045] 2. Turn on the driving system of the driving and passive wheels, and set the line speed to 1m / min.

[0046] 3. After all the solution is electrospun from the nozzle, turn on the receiving device and set the linear speed of the receiving device to 5m / min.

[0047] 4. After the system is stable, take out the PA nanofiber membrane. The average surface density of the PA nanofiber membrane is 3.2g / cm2, the average thickness is 8μm, the average deviation of the surface density is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com