Novel oil removing and setting process and device for chemical fiber fabric production

A fabric and chemical fiber technology, applied in the field of new degreasing and shaping process and its device, can solve the problems of discontinuous shaping production, large consumption of water and steam, large floor area of degreasing and washing line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

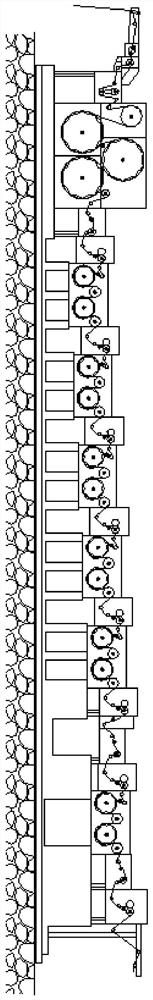

Method used

Image

Examples

Embodiment 1

[0044]Processing fabric: warp knitted fabric, specifications: (1) 40D / 12F nylon filament (82%) + 40D ordinary spandex (18%); (2) 40D / 34F nylon filament matte (72%) + 40D ordinary Spandex (28%); (3) 30D / 34F nylon filament matte (81%) + 30D ordinary spandex (26%); (4) 50D / 48F nylon filament matte (74%) + 280D ordinary spandex ( 26%); (5) 50D / 24F polyester filament semi-gloss (74%) + 280D ordinary spandex (26%).

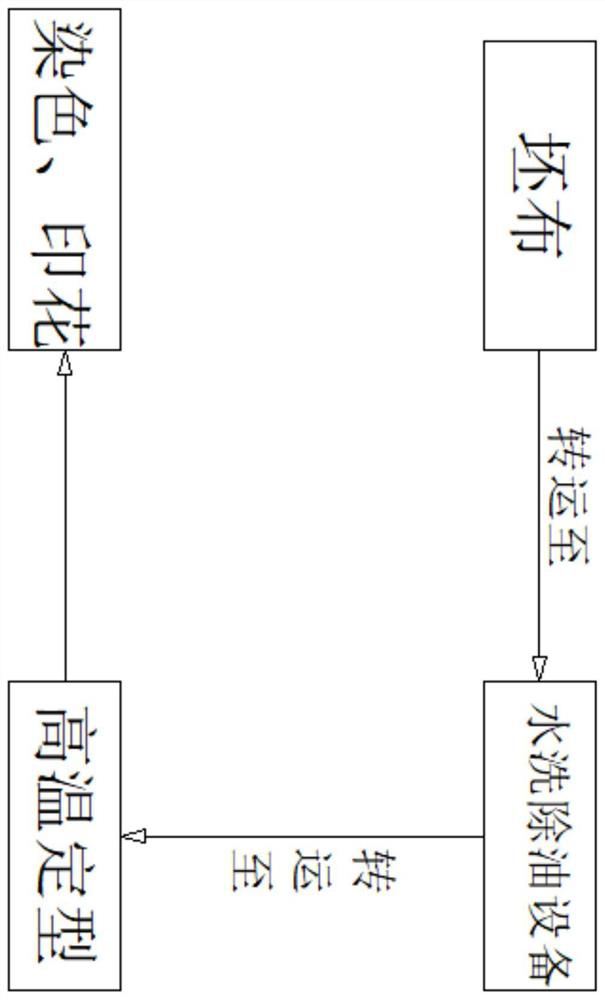

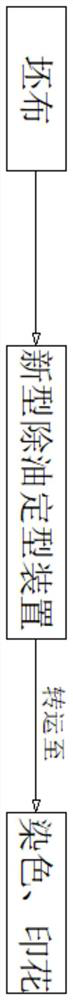

[0045] The specific process of this process embodiment is: gray cloth → ultrasonic degreasing (a) → padding water (or vacuum water absorption) (b) → shaping padding (c) → high temperature initial setting (d) → dyeing (e ).

[0046] The main process parameters of each process are as follows:

[0047] a. The number of ultrasonic waves is 3 times, and the 3 ultrasonic environments are: hot water at 65°C, clear water at room temperature, and clear water at room temperature. The frequency of ultrasonic waves is 30kHZ, and the power density is 0.35w / cm 2 ;

[0048] c. N...

Embodiment 2

[0062] Processing fabric: weft knitted fabric, the specifications can be: (6) 40D / 34F nylon filament glossy (76%) + 30D ordinary spandex (24%); (7) 75D / 72F polyester low elastic silk matte (85% ) +40D ordinary spandex (15%).

[0063] The specific process of this process embodiment is: gray cloth → ultrasonic degreasing (a) → padding water (or vacuum water absorption) (b) → shaping padding (c) → high temperature initial setting (d) → dyeing (e ).

[0064] The main process parameters of each process are as follows:

[0065] a. The number of ultrasonic waves is 3 times, and the 3 ultrasonic environments are: hot water at 65°C, clear water at room temperature, and clear water at room temperature. The frequency of ultrasonic waves is 30kHZ, and the power density is 0.35w / cm 2 ;

[0066] c. Nylon-type fabrics are grooved through anti-high temperature oxidizer 20g / l, and polyester fabrics are grooved with water;

[0067] d. The shaping temperature is 190°C, and the vehicle spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com