Variable diameter pyramid-type drilling powder discharge and pressure relief device

A pressure relief device, pyramid technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of low strength of spiral cutters, changing drill bit structure, and inability to form powder discharge space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention proposes a variable-diameter pyramid-type drilling powder discharge and pressure relief device. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

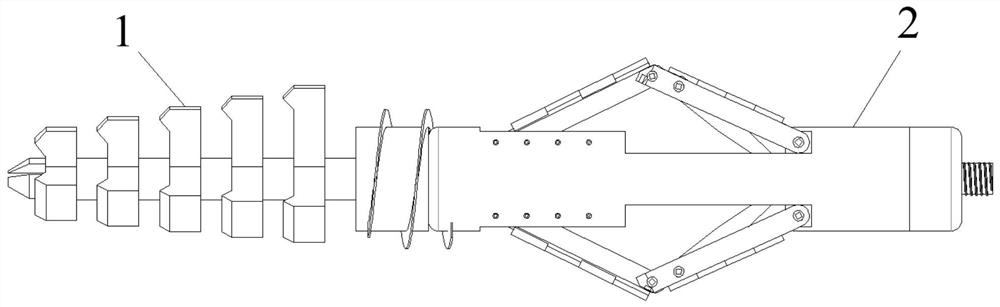

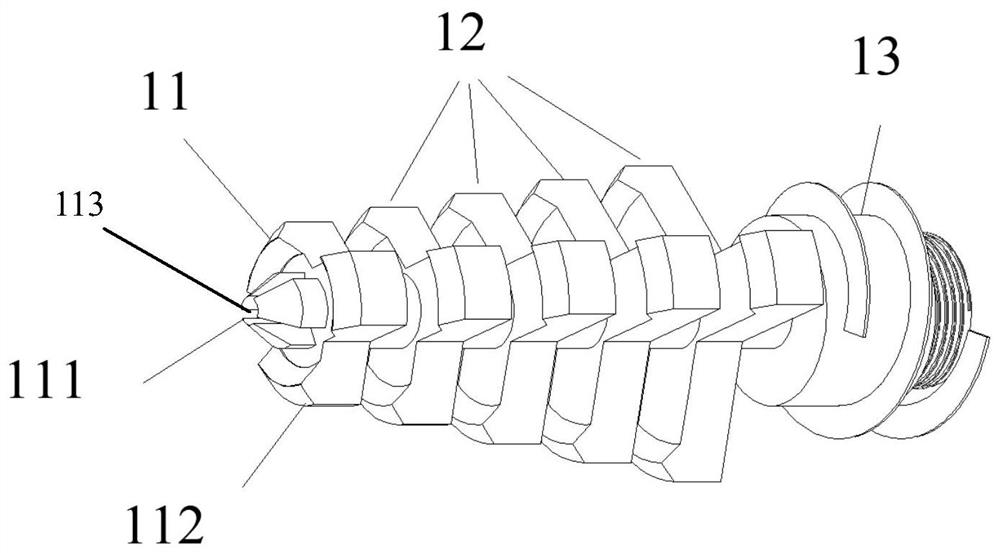

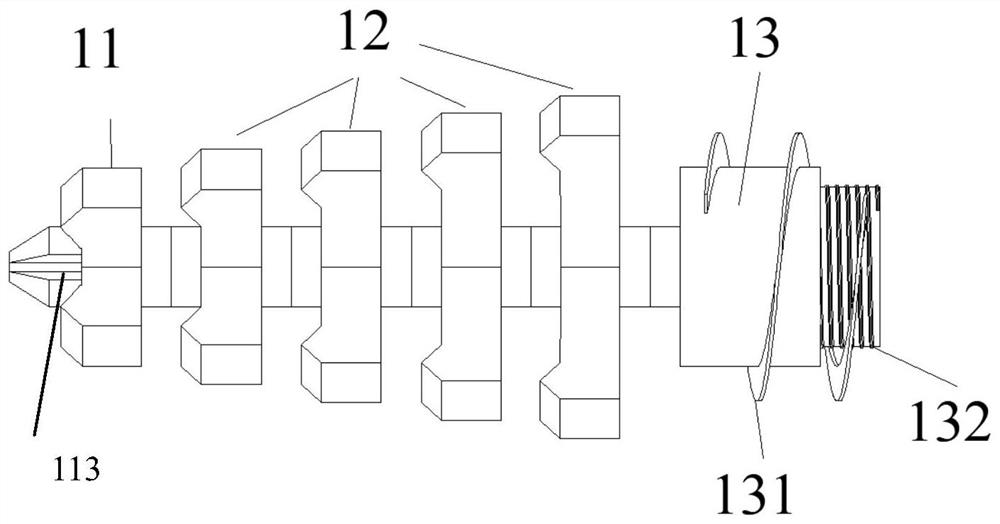

[0041] Such as figure 1 As shown, a variable-diameter pyramid-type drilling powder discharge and pressure relief device of the present invention mainly includes a pressure relief connecting rod 2 and a powder discharge pressure relief drill bit 1, and the powder discharge pressure relief drill bit 1 is installed on the front end of the pressure relief connecting rod 2 , in actual use, the rear end of the pressure relief connecting rod 2 is connected to the required drilling rod in the drilling process.

[0042] The pressure relief connecting rod 2 used in the present invention adopts the pressure relief connecting rod of the same structure in the application n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com