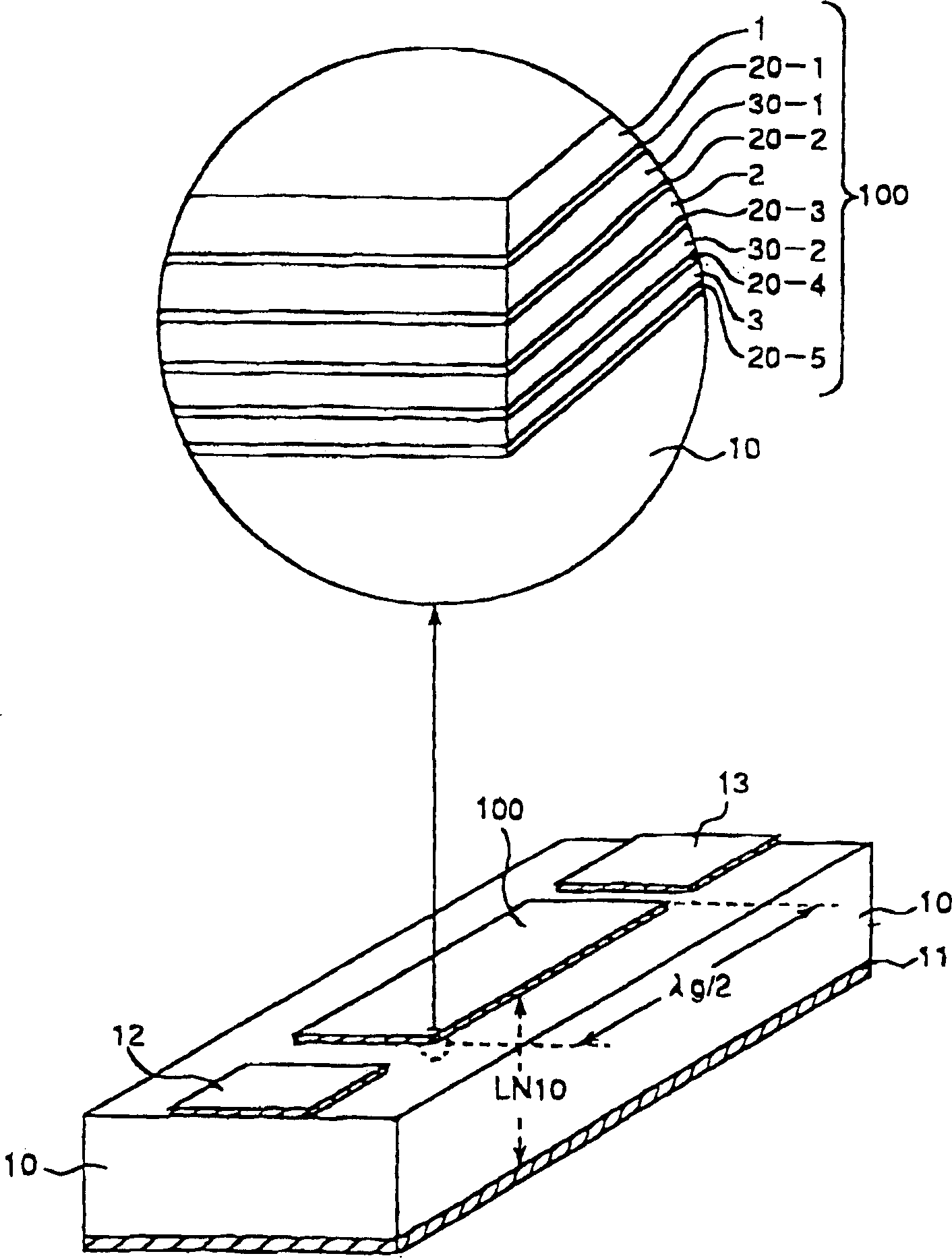

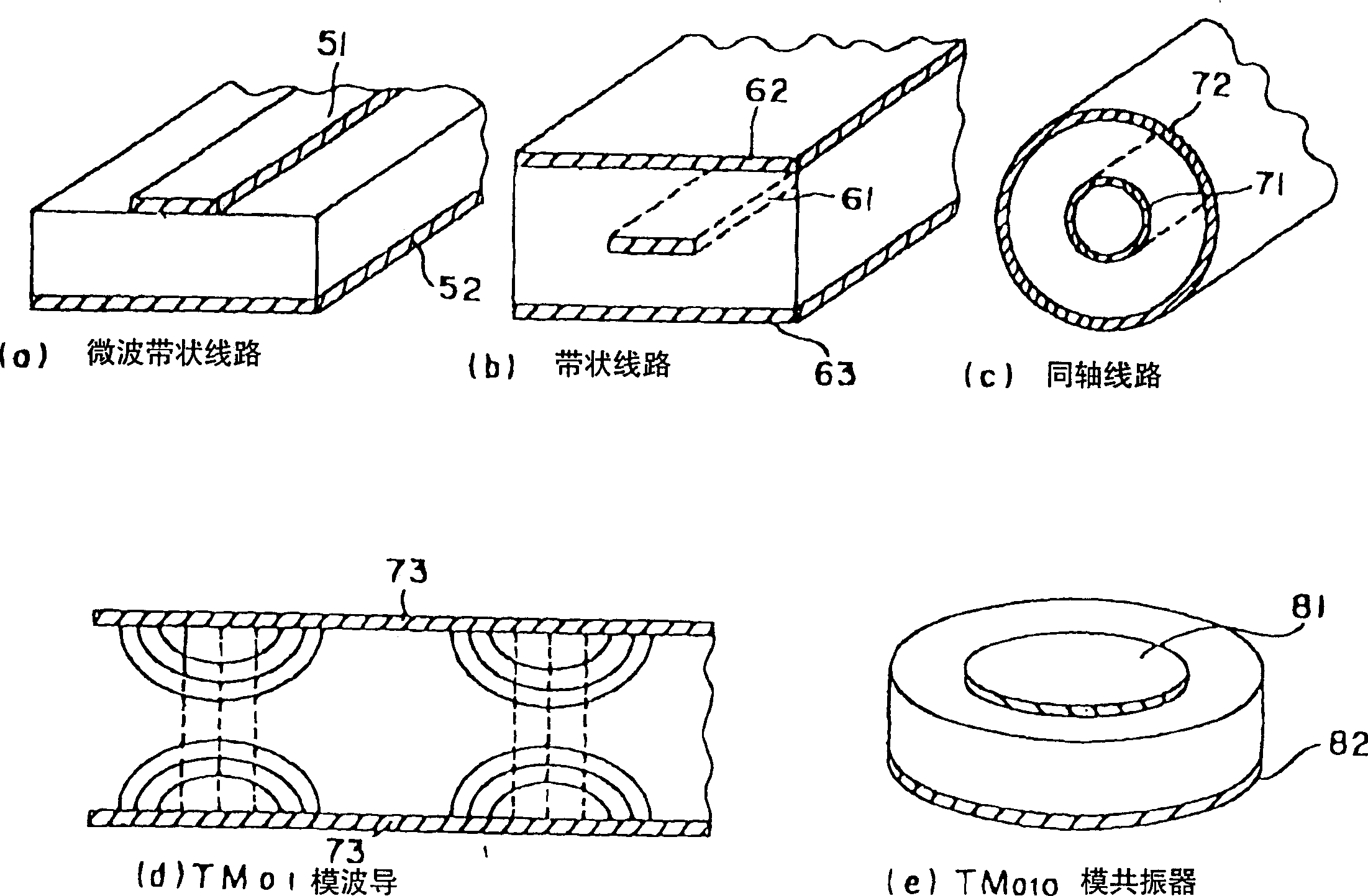

Multilayer thin film electrode, HF transmission line, HF resonator and HF filter

A multi-layer film and resonator technology, applied in circuits, resonators, waveguides, etc., can solve the problems of reduced reliability, low adhesion strength, and unsatisfactory suppression of skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

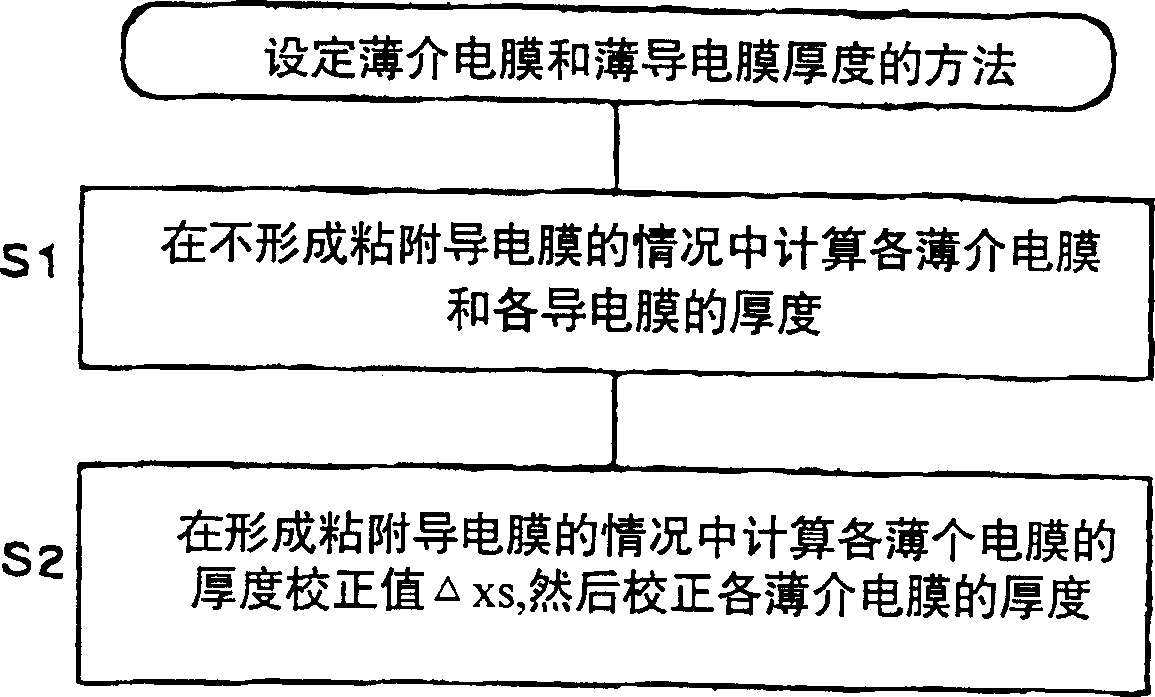

Method used

Image

Examples

Embodiment 1

[0064] For comparison, first, the results obtained from the evaluation of the conventional multilayer thin film electrodes will be described, and second, the results of Example 1 will be described. Table 2 provides the obtained result to the evaluation of existing multilayer thin film electrode, and this multilayer thin film electrode has five layers of thin conductive film layers (the number of film layers refers to the number of thin conductive film layers in the future), under the above-mentioned parameter conditions , no adhesive conductive film was formed.

[0065] Table 2 sets the film thickness and Q rise rate of existing multilayer thin film electrodes (5 layers)

[0066] Thickness of thin conductive film 1 4.2 μm (top layer)

[0067] Thickness of other thin conductive film 1: 0.756 μm

[0068] Thickness of thin dielectric film 0.0968μm

[0069] Q increase rate 2.39 times

[0070]In the existing multilayer thin film electrodes shown in Table 2, when between the die...

Embodiment 2

[0079] In Example 2, the Q rise rate of a multilayer thin film electrode having ten layers, which was prepared according to the same parameters as in Example 1, was evaluated. Table 4 shows the thickness and Q rise rate of setting the existing multilayer thin film electrodes. Table 5 shows the thickness and Q rise rate of the multilayer thin film electrode of Setting Example 2, which provides an adhesive conductive film, and corrects the thickness of each thin dielectric film to a predetermined thickness.

[0080] Table 4 sets the film thickness and Q rise rate of existing multilayer thin film electrodes (10 layers)

[0081] Thickness of thin conductive film 1 4.2 μm (top layer)

[0082] Thickness of other thin conductive film 1: 0.556 μm

[0083] Thickness of thin dielectric film 0.0686μm

[0084] Q increase rate 3.33 times

[0085] Table 5 sets the film thickness and Q rise rate of embodiment 2 multilayer thin film electrode (10 layers)

[0086] Thickness of thin conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com