Preparation method of coated implant

An implant and coating technology, applied in the field of medical devices, can solve the problems of increasing the inner and outer diameters of the coating implants, low coating strength, foreign body sensation in the human body, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The invention provides a method for preparing a covered implant, comprising the following steps:

[0063] Combination steps:

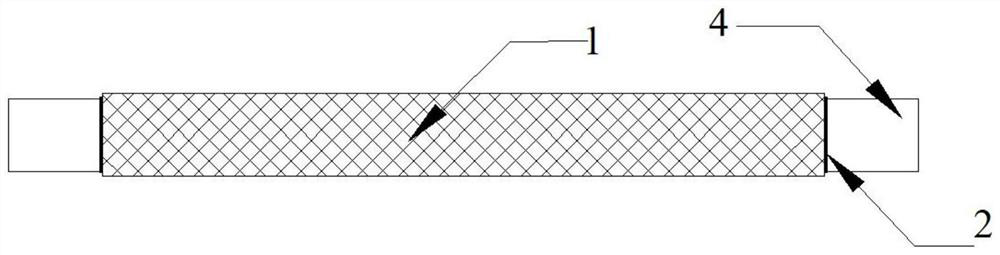

[0064] Wrap the inner film on the supporting mold;

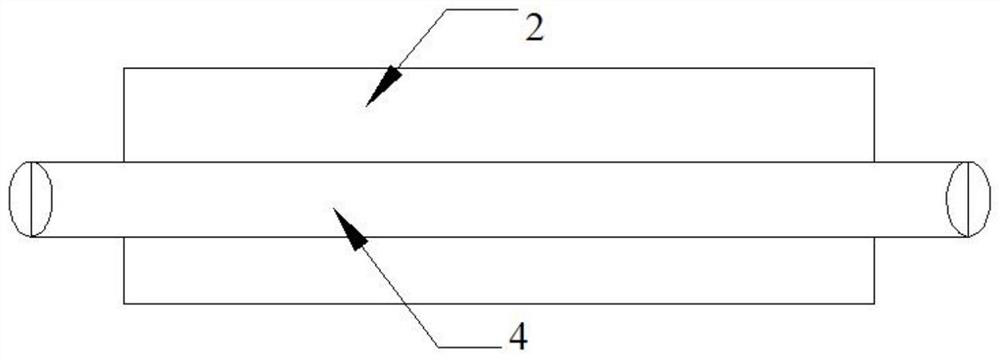

[0065] Sleeve the implant on the supporting mold with the inner film wrapped around it;

[0066] wrapping an outer covering over the implant to form an implant component;

[0067]Sleeve a heat-shrinkable tube on the implant assembly;

[0068] Heating condensation steps:

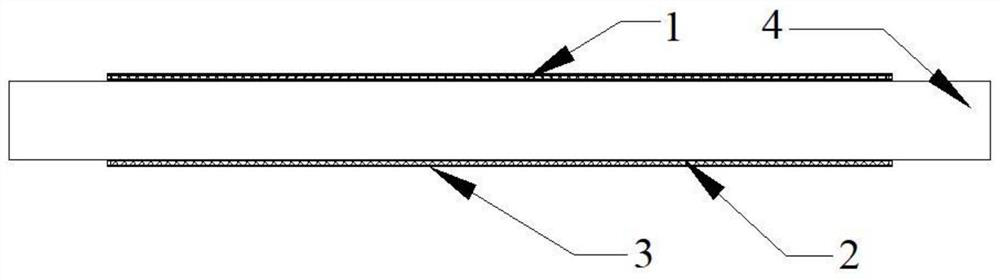

[0069] heating, using the heat-shrinkable tube to condense the implant component, so that the inner layer film and the outer layer film are bonded and pressed together under the condensation extrusion of the heat-shrinkable tube, so that coating the implant;

[0070] Cooling and disassembly steps:

[0071] After the implant assembly and the heat-shrinkable tube are cooled, the heat-shrinkable tube and the supporting mold are removed to obtain a covered implant.

[0072] The coating of the implant in the present inventi...

Embodiment 1

[0082] This example is illustrated by the preparation of covered vascular stents. Among the existing surgical methods and methods of vascular intervention, percutaneous transcatheter intervention, implantation of various artificial vascular stents, artificial blood vessels, artificial valves and other implants have become the mainstay of treatment. An important method for vascular stenosis, hemangioma, and valvular disease, especially the application of covered vascular stents is becoming more and more extensive. For the covered stent graft prepared by purely physical coating method, the increase of the inner and outer diameter not only leads to the obstruction of blood flow after the covered vascular stent is implanted in the blood vessel, but also increases the interventional delivery catheter used for the pre-installed stent. , resulting in unnecessary additional complications; under the long-term blood flow, the inner and outer layers of the stent have a great risk of teari...

Embodiment 2

[0097] This example illustrates the preparation of a membrane-covered vena cava filter. The Vena Cava Filter (VCF) is a device similar to a filter and is usually deployed in the inferior vena cava to physically intercept floating thrombus and prevent A deep vein thrombosis travels to the lungs causing pulmonary thromboembolism. Since the emergence of the Mobin-Uddin umbrella VCF in 1967, VCF has made great progress in structural design and performance, and has become more and more widely used clinically. All VCFs on the Internet have some disadvantages that affect clinical development. Specifically: First, there is a risk of rupture of the umbrella-shaped side branches under the washing of the blood flow. The broken umbrella-shaped side branches flow in the human blood vessels and enter the heart, which will be fatal to the patient. Second, in order to prevent the filter from shifting, there will be some anchors at the end of the umbrella-shaped side branches for fixation in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com