Graphite high-temperature antioxidant capable of being quickly dried at normal temperature and application thereof

A fast-drying, anti-oxidant technology, applied in the field of graphite anti-oxidation, can solve problems such as difficult large-scale industrialization and practical application obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

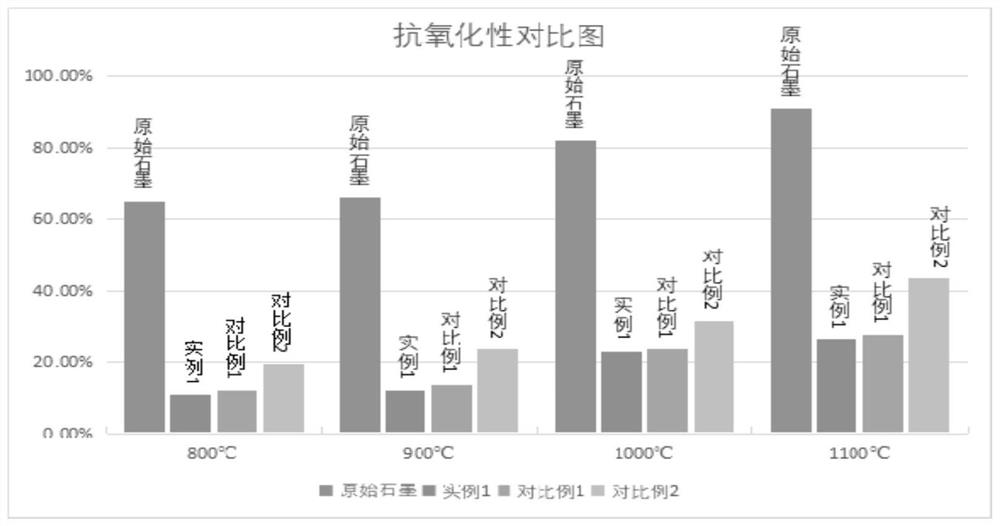

Image

Examples

Embodiment 1

[0025] (1) Select graphite base material, polish the surface and ultrasonically treat it with absolute ethanol. After the surface is dry, put it in an oven and place it at 100°C for 2 hours for later use.

[0026] (2) Preparation of graphite high-temperature antioxidant that can be quickly dried at room temperature: weigh 57g aluminum dihydrogen phosphate solution, 6g sodium hexametaphosphate, 1g disodium hydrogen phosphate, 7g silica sol, 2g silane coupling agent, dodecyl benzene sulfonate Sodium 1g is mixed with 3g of glycerol and 23g of distilled water for 30min ultrasonic treatment to obtain a graphite high temperature antioxidant that is quickly dried at room temperature;

[0027] (3) Put the processed graphite sample into the prepared graphite high-temperature antioxidant that is quickly dried at room temperature and press it under vacuum to 0.5 MPa, and hold the pressure for 10 minutes, so that the inside and the surface are fully adsorbed on the uniform room temperature fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com