Polypropylene foam material and preparation method thereof

A foamed material, polypropylene technology, applied in the field of polypropylene foamed material and its preparation, can solve the problems of high processing cost, difficult foaming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

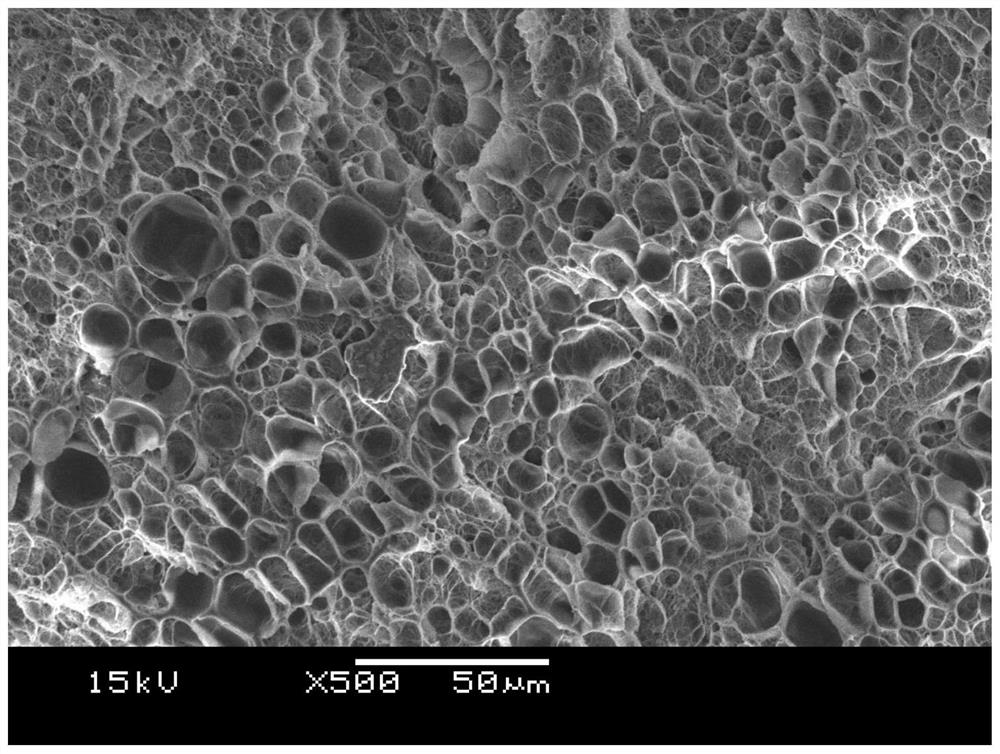

Embodiment 1

[0039] Polypropylene granules (5-10g) are hot-pressed into flakes using a hot press, and the flake raw materials are placed in an autoclave, and co-foaming agent ethanol is added in an amount of CO under the experimental temperature and pressure. 2 5wt% by mass, with CO 2 Purge three times to remove the air in the kettle, then place the autoclave in an oil bath, heat it to 140°C at a constant rate (8°C / min), keep it warm for half an hour, and then fill it with high-pressure (15MPa) CO 2 , the pressure is controlled at 15MPa, and the sheet is saturated for 1.5h to the equilibrium of dissolution and diffusion, and then the pressure is quickly released, and the high-pressure CO in the container is released within 1s. 2 After discharging, put the autoclave into an ice-water bath to cool and set the shape to obtain a microporous foam material. The scanning electron microscope picture of the polypropylene foam product that makes is as follows figure 1 .

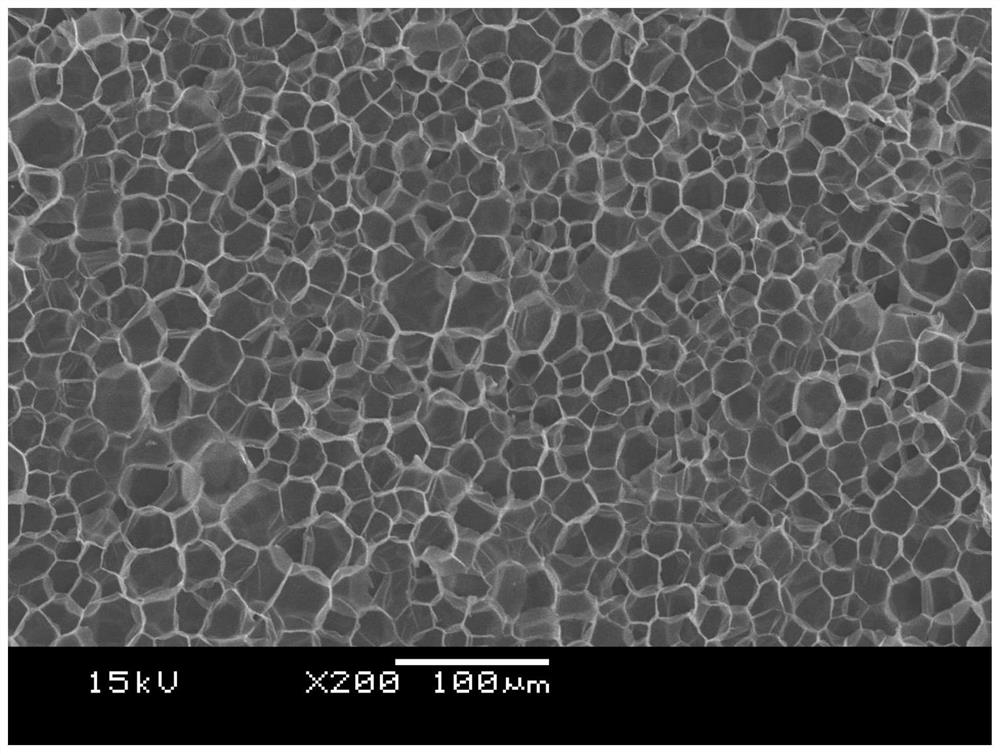

Embodiment 2

[0041] Polypropylene granules (5-10g) are hot-pressed into sheets using a hot press, and the sheet-like raw materials are placed in an autoclave, and a co-foaming agent butanol is added in an amount of CO under the experimental temperature and pressure. 2 5wt% by mass, with CO 2 Purge three times to remove the air in the kettle, then place the autoclave in an oil bath, heat it to 135°C at a constant rate (8°C / min), keep it warm for half an hour, and then fill it with high-pressure (15MPa) CO 2 , the pressure is controlled at 15MPa, and the sheet is saturated for 1.5h to the equilibrium of dissolution and diffusion, and then the pressure is quickly released, and the high-pressure CO in the container is released within 1s. 2 After discharging, put the autoclave into an ice-water bath to cool and set the shape to obtain a microporous foam material. The scanning electron microscope picture of the polypropylene foam product that makes is as follows figure 2 .

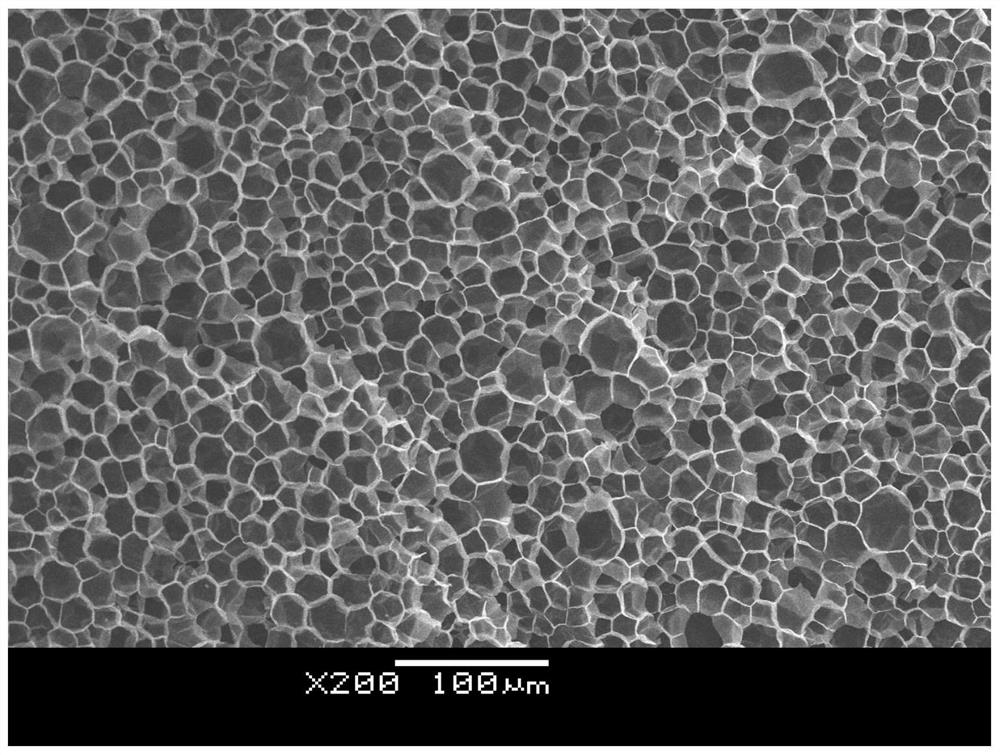

Embodiment 3

[0043] Polypropylene granules (5-10g) are hot-pressed into sheets using a hot press, and the sheet-like raw materials are placed in an autoclave, and a co-foaming agent, hexanol, is added in an amount of CO under the experimental temperature and pressure. 2 5wt% by mass, with CO 2 Purge three times to remove the air in the kettle, then place the autoclave in an oil bath, heat it to 130°C at a constant rate (8°C / min), keep it warm for half an hour, and then fill it with high-pressure (15MPa) CO 2 , the pressure is controlled at 15MPa, and the sheet is saturated for 1.5h to the equilibrium of dissolution and diffusion, and then the pressure is quickly released, and the high-pressure CO in the container is released within 1s. 2 After discharging, put the autoclave into an ice-water bath to cool and set the shape to obtain a microporous foam material. The scanning electron microscope picture of the polypropylene foam product that makes is as follows image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com