A polymer composite material for space neutron shielding and its preparation method

A composite material and polymer technology, applied in the field of polymer composite materials for space neutron shielding and its preparation, can solve the problem of low polarity of polyethylene molecular chain, poor compatibility, poor mechanical strength and poor neutron shielding performance and other problems, to achieve the effect of simple process, low equipment cost, and improved interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a polymer composite material for space neutron shielding and a preparation method thereof. The polymer composite material is a nanocomposite material, and has the characteristics of light weight and good neutron shielding performance. The technical solution realizes:

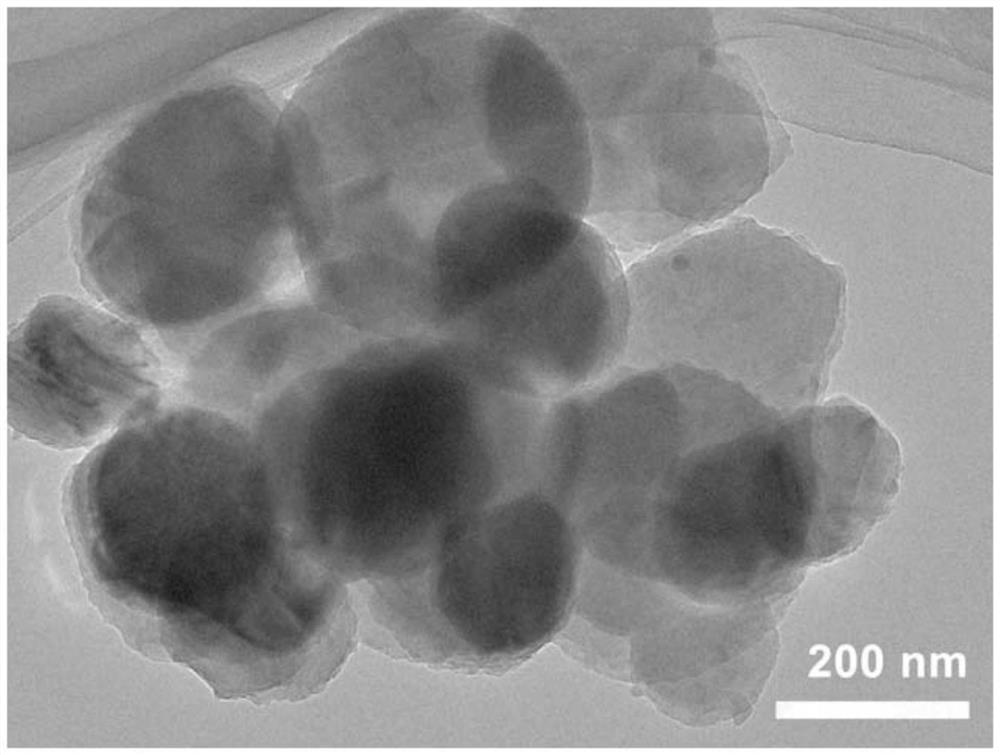

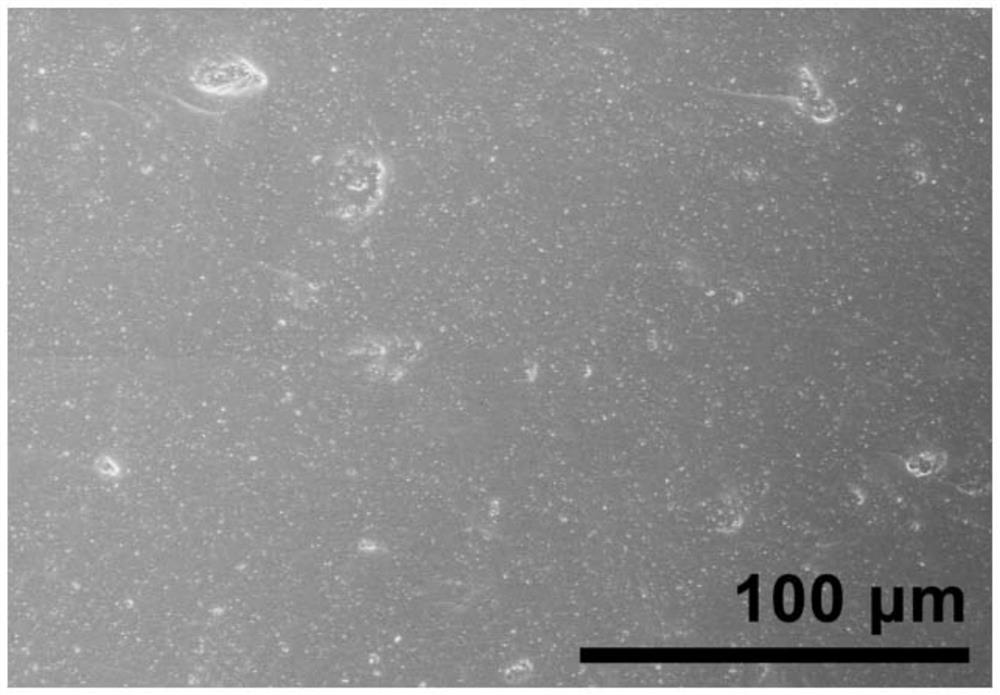

[0040] (1) The matrix of the nanocomposite is polyethylene, and the filler is hexagonal boron nitride nanosheets with a two-dimensional sheet structure; the surface of the boron nitride nanosheets is chemically modified and bound to the polyethylene polymer chain through covalent bonds It can effectively inhibit the agglomeration of the nanosheets and realize the uniform dispersion of the nanosheets in the polyethylene matrix.

[0041] (2) Two-dimensional boron nitride nanosheets are made of hexagonal boron nitride micro-particles as raw materials, and are made into dry powder by liquid-phase-assisted ultrasonic peeling, high-speed centrifugal sieving and freeze-drying, with...

Embodiment 1

[0047] Take a certain amount of hexagonal boron nitride micro-particles, sieve, dry, mix with absolute ethanol, then add silane coupling agent KH550 (γ-aminopropyltriethoxysilane), use ultrasonic at room temperature and normal pressure The crusher was sonicated for 5h. After three times of centrifugation and washing, the unstripped boron nitride micro-particles and other organic impurities are removed to obtain a boron nitride nanosheet dispersion. Finally, the solvent is removed by freeze-drying to obtain a dry powder of boron nitride nanosheets.

Embodiment 2

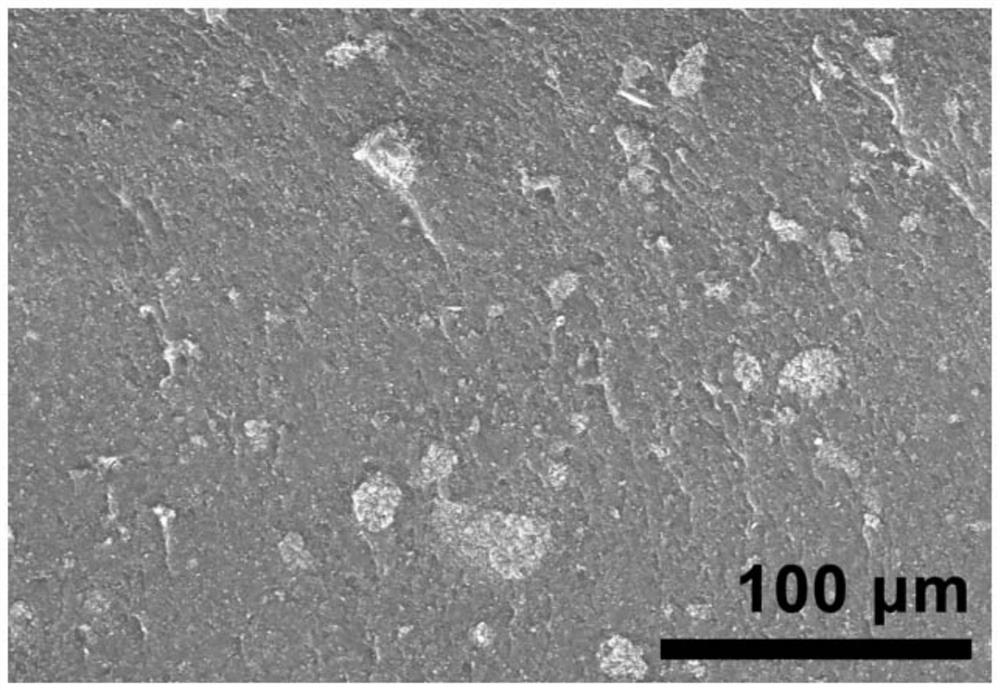

[0049] The prepared boron nitride nanosheet powder and the maleic anhydride grafted polyethylene particles are physically mixed evenly, added to an internal mixer, mixed and reacted at 120-180 ° C for 30 minutes, and finally extruded to obtain a surface covalently grafted polyethylene. Boron nitride nanosheet particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com