Organic/inorganic hybrid three-component Janus particle and preparation method thereof

A three-component, particle technology, applied in the field of organic/inorganic hybrid three-component Janus particles and preparation, can solve the problems of single size and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

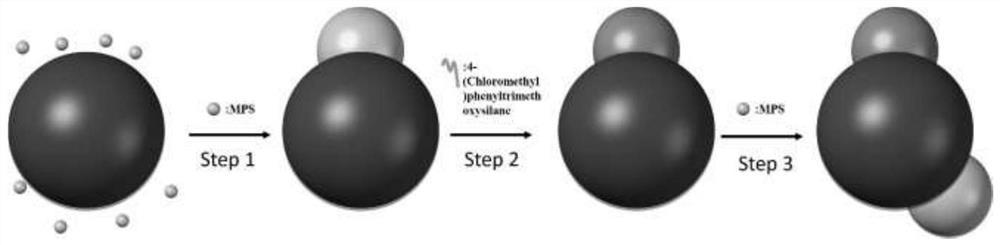

[0051] figure 1 A schematic diagram showing the preparation method of the organic / inorganic hybrid three-component Janus particle of the present invention. The preparation method of the organic / inorganic hybrid three-component Janus particles provided by the invention is to prepare the organic / inorganic hybrid three-component Janus particles by emulsion polymerization. see figure 1 , the method includes the following steps:

[0052] 1) dispersing polymer microspheres in water to obtain seed emulsion;

[0053] 2) Add the silane coupling agent emulsion to the seed emulsion, carry out the polymerization reaction under mechanical stirring, and produce phase separation to obtain the Janus particle emulsion; the silane coupling agent emulsion includes the silane coupling agent monomer and the polymerization initiator ;

[0054] 3) drying the Janus particle emulsion obtained in step 2) by spray drying or freeze-drying to obtain Janus particles separated from organic and inorganic...

Embodiment 1

[0063] Disperse 1 g of cross-linked polystyrene hollow spheres in 23.6 g of deionized water, add 0.0236 g of sodium lauryl sulfate as a surfactant, and stir mechanically to form a uniform seed emulsion.

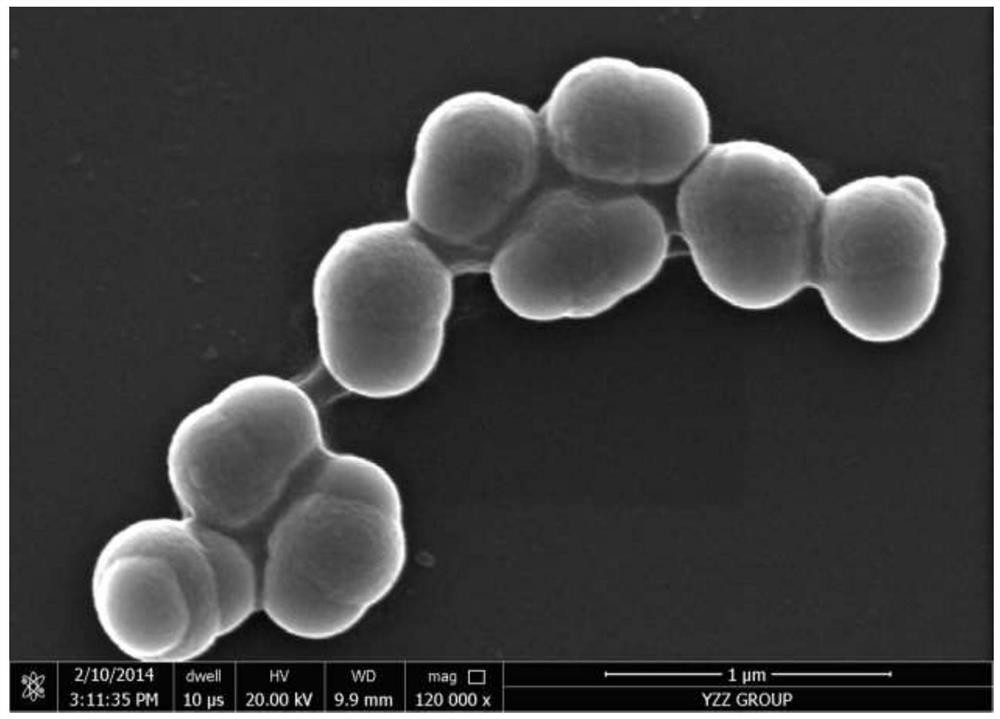

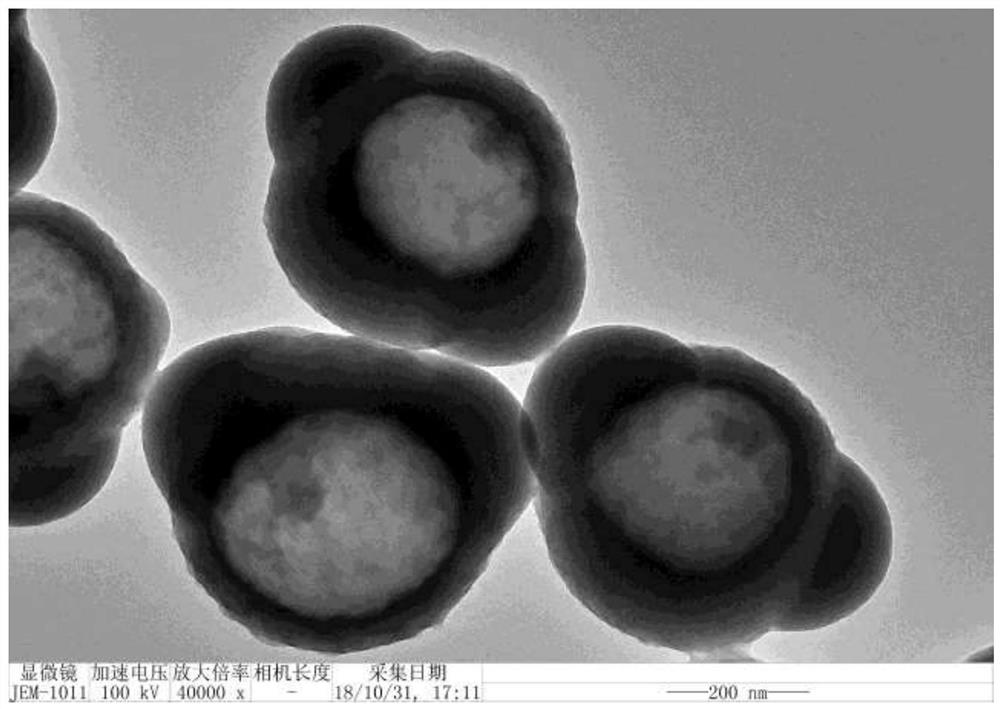

[0064] 1g silane coupling agent monomer (3-(methacryloyloxy)propyltrimethoxysilane (MPS)), 0.01g polymerization initiator (potassium persulfate (KPS)), 0.02g surfactant (10 Sodium dialkyl sulfate (SDS)) and 10 g of deionized water were mixed into a uniform silane coupling agent emulsion by ultrasonic. The seed emulsion containing the cross-linked styrene hollow spheres was heated to 70° C., and the silane coupling agent emulsion was added to the seed sphere emulsion containing the cross-linked styrene hollow spheres at a speed of 2.5 rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours to obtain a silica / polystyrene Janus particle emulsion.

[0065] The emulsion is dried by a spray-drying method...

Embodiment 2

[0067] Disperse 1 g of cross-linked polystyrene hollow spheres in 23.6 g of deionized water, add 0.0236 g of sodium lauryl sulfate as a surfactant, and stir mechanically to form a uniform seed emulsion.

[0068] With 0.5g silane coupling agent monomer (3-(methacryloxy) propyltrimethoxysilane (MPS)), 0.005g polymerization initiator (potassium persulfate (KPS)), 0.02g surfactant ( Sodium dodecyl sulfate (SDS)) and 10 g of deionized water were mixed into a uniform silane coupling agent emulsion by ultrasonic. The seed emulsion containing the cross-linked styrene hollow spheres was heated to 70° C., and the silane coupling agent emulsion was added to the seed sphere emulsion containing the cross-linked styrene hollow spheres at a speed of 2.5 rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours to obtain a silica / polystyrene Janus particle emulsion.

[0069] The emulsion is dried by a spray-drying me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com