Controllable batch preparation method of organic/inorganic hybrid janus particles

A particle and inorganic technology, applied in the field of controllable batch preparation of organic/inorganic hybrid Janus particles, can solve the problem of difficult to achieve strict partitioning of chemical composition and fine control of microstructure, inability to obtain submicron or even nanoscale materials, lack of Janus particle fine-tuning methods and other issues, to achieve high industrial application potential, realize batch industrial production, and facilitate multi-functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

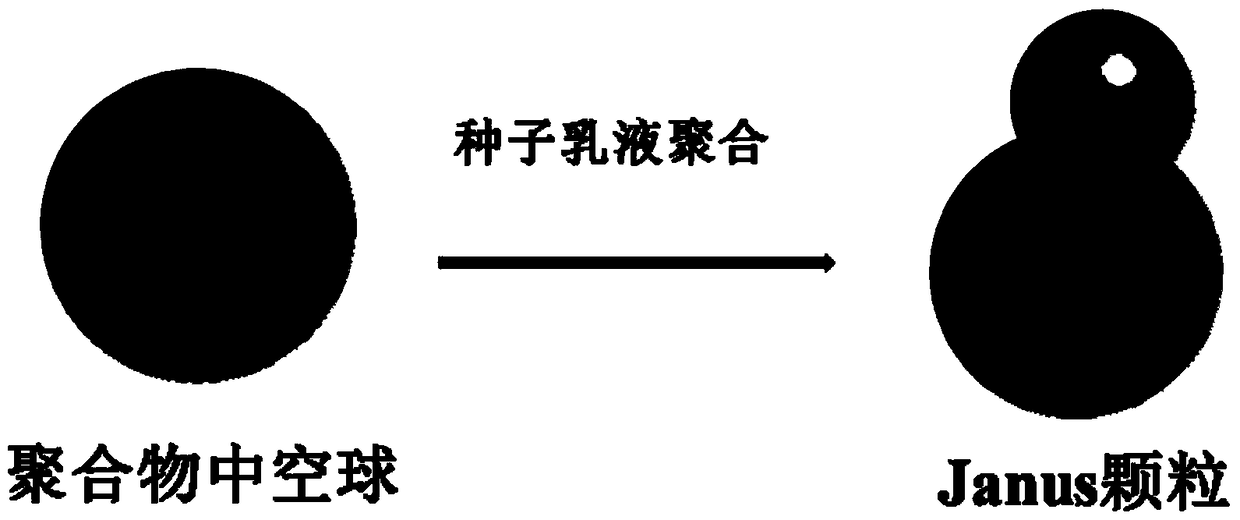

[0050] Based on the present invention, the present invention provides organic / inorganic hybrid Janus particles with separated organic and inorganic parts and methods for their preparation, such as figure 1 As shown, it is a schematic diagram of the preparation process of organic / inorganic hybrid Janus particles prepared by the present invention. The organic / inorganic hybrid Janus particles provided by the present invention are prepared by emulsion polymerization. The method comprises the steps of:

[0051] 1) dispersing polymer hollow spherical particles in water to obtain seed emulsion;

[0052] 2) Add the silane coupling agent emulsion to the seed emulsion, carry out the polymerization reaction under mechanical stirring, and produce phase separation to obtain the Janus particle emulsion; the silane coupling agent emulsion includes the silane coupling agent monomer and the polymerization initiator .

[0053] 3) The Janus particle emulsion obtained in step 2) is spray-dried ...

Embodiment 1

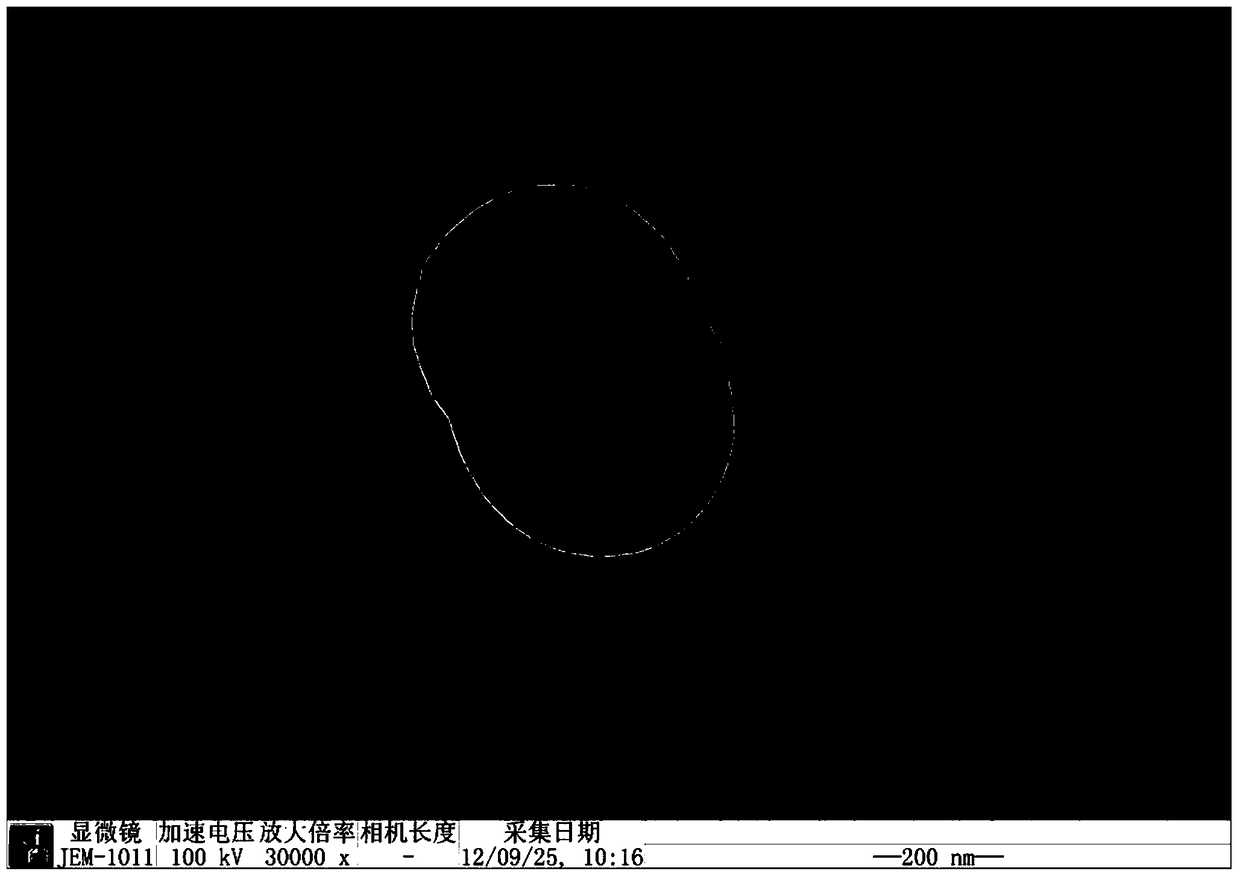

[0057] Add 20 g of deionized water to 2.667 g of linear polystyrene (PS) hollow sphere emulsion with a solid content of 37.5%, and mechanically stir to form a uniform seed sphere emulsion (with a solid content of 4.41%). Adopt 2.0g oil-soluble silane coupling agent monomer (3-(methacryloxy) propyltrimethoxysilane (MPS)), initiator (1% potassium persulfate solution (KPS)) 2.0g, 0.02g Surfactant (sodium dodecyl sulfate (SDS)) and 10g deionized water ultrasonically form a homogeneous silane coupling agent monomer emulsion (silane coupling agent monomer 14.2%, initiator 1.42‰; surfactant 1.42‰, The balance is water). The rotation speed is 400rpm and mechanical stirring is performed, the seed emulsion is heated to 70°C, and the above-mentioned silane coupling agent monomer emulsion is added to the seed ball emulsion at a speed of 2.5rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours. At the beginni...

Embodiment 2

[0059]Add 10 g of deionized water to 2.667 g of linear polystyrene (PS) hollow sphere emulsion with a solid content of 37.5%, and mechanically stir to form a uniform seed sphere emulsion (with a solid content of 4.41%). Adopt 1.0g oil-soluble silane coupling agent monomer (3-(methacryloyloxy) propyltrimethoxysilane (MPS)), initiator (1% potassium persulfate solution (KPS)) 2.0g, surface activity Agent (sodium dodecyl sulfate (SDS)) 0.02g and 10g deionized water ultrasonically form a homogeneous monomer emulsion (silane coupling agent monomer 14.2%, initiator 1.42‰; surfactant 1.42‰, the balance is water ). The rotation speed is 400rpm and mechanical stirring is performed, the seed emulsion is heated to 70° C., and the silane coupling agent monomer emulsion is added to the seed ball emulsion at a speed of 2.5 rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours to obtain a silica / polystyrene Janus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com