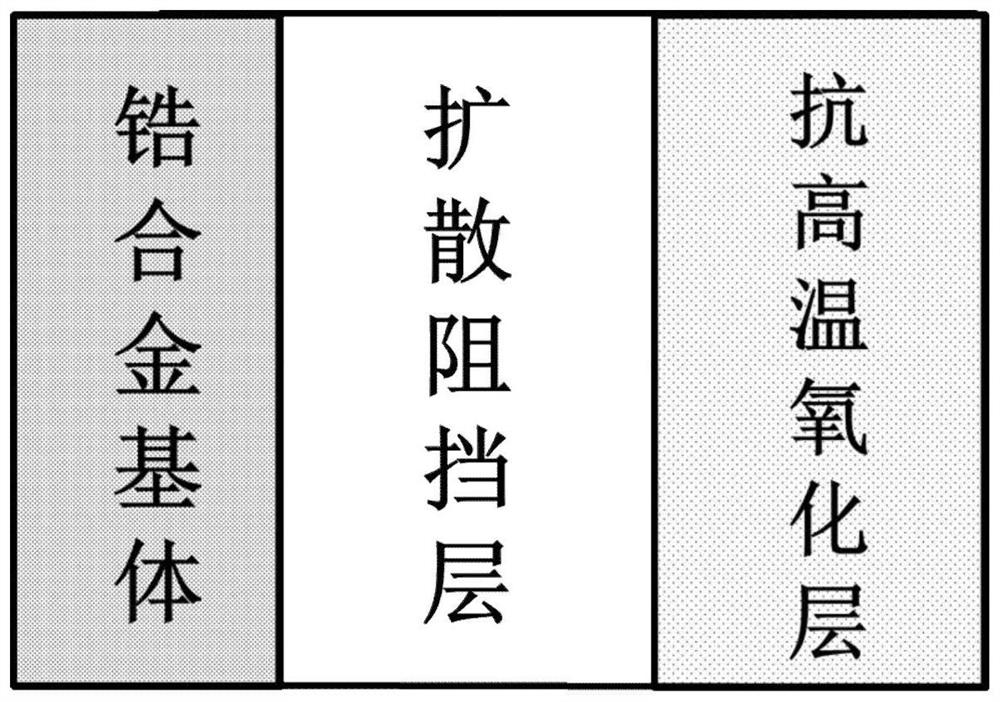

Accident-tolerant nuclear fuel cladding double-layer coating structure and preparation method thereof

A double-layer coating, double-layer cladding technology, applied in the field of nuclear materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the accident-tolerant nuclear fuel cladding double-layer coating structure in this embodiment includes the following steps:

[0033] Sandblasting is performed on the surface of the zirconium alloy plate first to improve its bonding ability with metal powder.

[0034] Use a 500-mesh sieve to screen out Ta, Ti, W, V and Cr metal powders with particle diameters below 30 μm. Prepare W55Ta20Ti10V10Cr5 alloy powder according to mass percentage.

[0035] Dry the above alloy powder in a drying oven for 30 minutes at a drying temperature of 100°C.

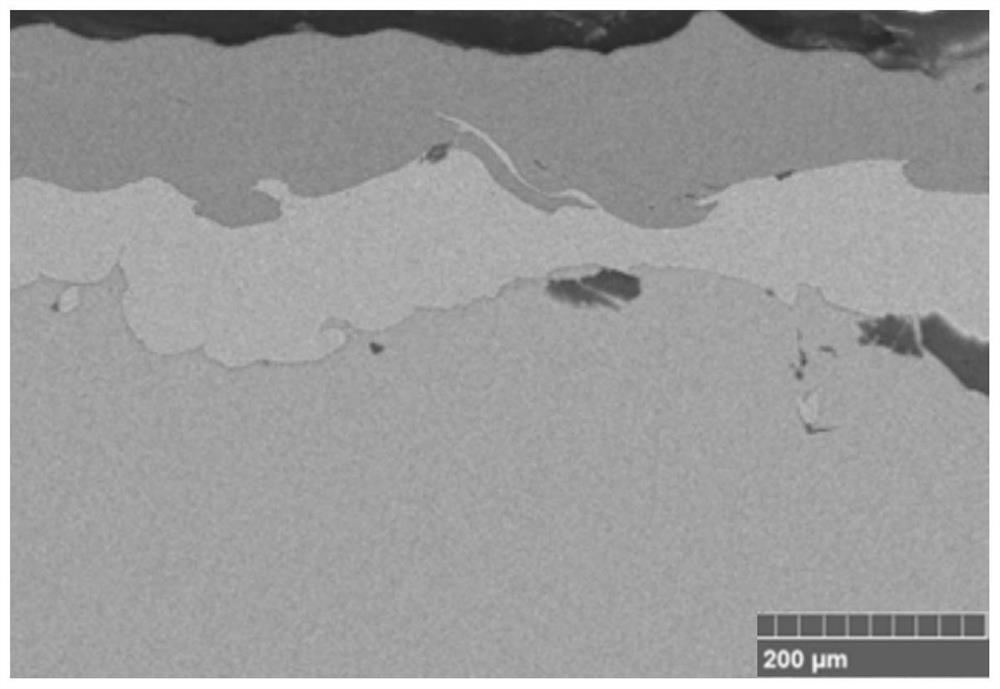

[0036] Use PCS-2000 type cold spraying instrument to cold spray diffusion barrier layer on the surface of zirconium alloy plate. The specific process parameters are: air pressure 4Mpa, gas temperature 750℃, alloy powder feed rate 0.25rpm, spray gun moving speed 800mm / s .

[0037] The cold spray gun is used to feed low-speed, large-size micro-forged particles, and through the hammering and forging action of ...

Embodiment 2

[0043] The preparation method of the accident-tolerant nuclear fuel cladding double-layer coating structure in this embodiment includes the following steps:

[0044] Sandblasting is performed on the surface of the zirconium alloy plate first to improve its bonding ability with metal powder.

[0045] Use a 500-mesh sieve to screen out Ta, Ti, W, V and Cr metal powders with particle diameters below 30 μm. According to the mass percentage, the alloy powder of Ta45W25Ti15V5Cr5 is prepared.

[0046] Dry the above alloy powder in a drying oven for 30 minutes at a drying temperature of 100°C.

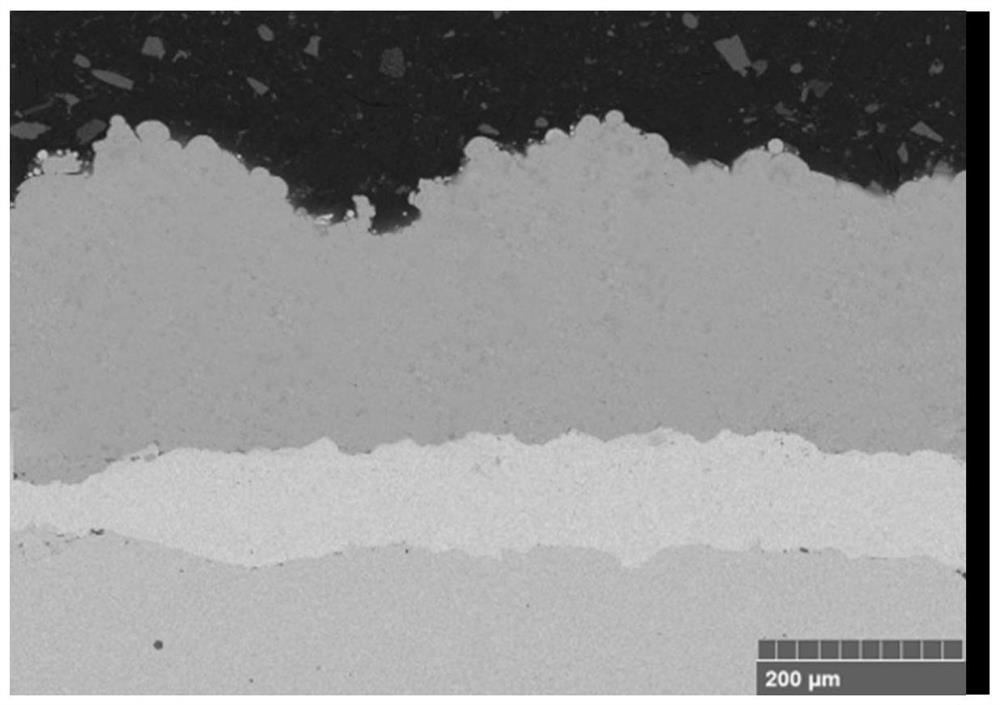

[0047] PCS-2000 cold spraying equipment is used to cold spray the diffusion barrier layer on the surface of the zirconium alloy plate. The specific process parameters are: air pressure 4.5Mpa, gas temperature 800 ℃, alloy powder feed rate 0.35rpm, spray gun moving speed 850mm / s.

[0048] The cold spray gun is used to feed low-speed, large-size micro-forged particles, and through the hammer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com