Box structure with vacuum insulating layer and refrigerator

A vacuum insulation layer and box structure technology, which is applied in household refrigerators, household appliances, cooling fluid circulation devices, etc., can solve the problems of box volume ratio reduction, increase of foam layer thickness, and production cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

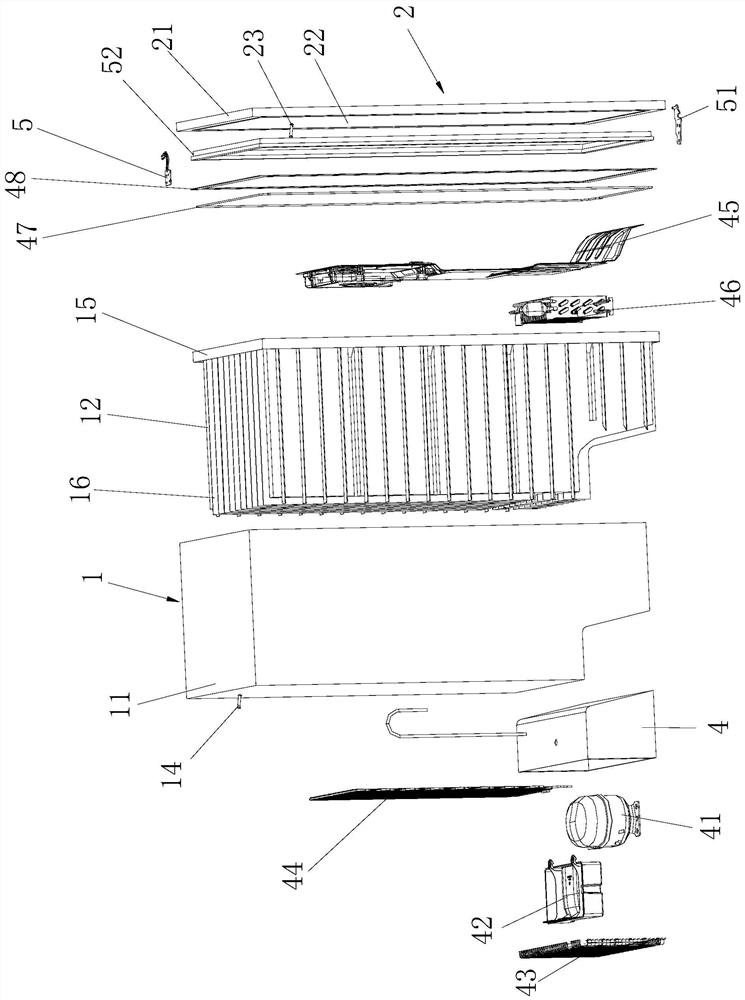

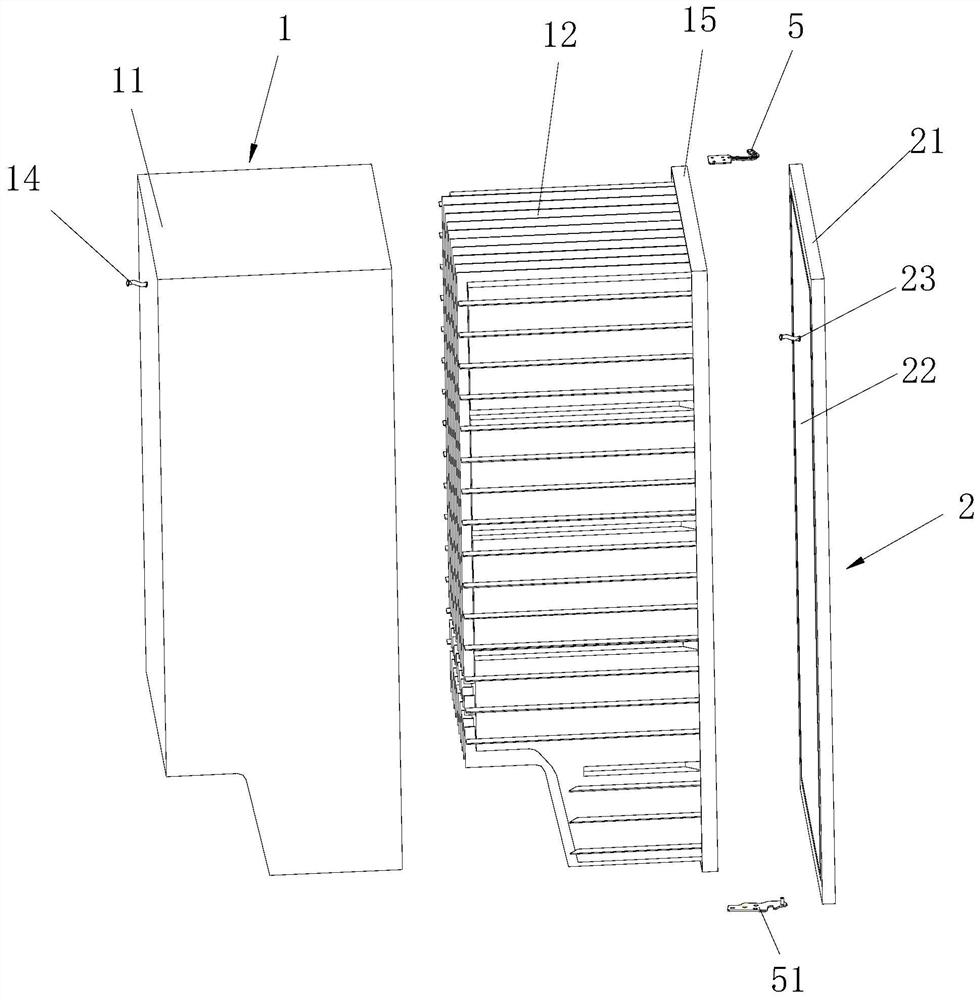

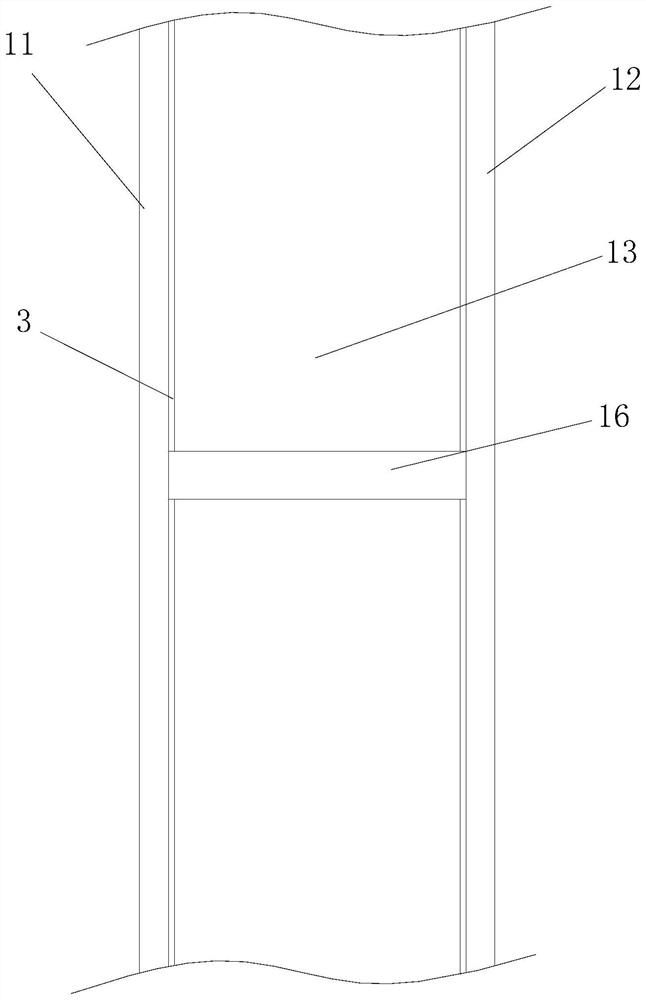

[0032] combine Figure 1 to Figure 3 , a box structure with a vacuum insulation layer, comprising a vacuum box 1 and a vacuum box door 2 connected to the front end of the vacuum box 1, the vacuum box 1 includes a box shell 11 and a box inner shell 12, the box shell 11 The first aluminum foil layer 3 is provided on the inner surface of the box inner shell 12 and the outer surface.

[0033] The inside and outside of the inner surface of the box shell 11 and the outside surface of the box inner shell 12 are determined relative to the assembly positions of the box shell 11 and the box inner shell 12. At this time, the box inner shell 12 is assembled with the box shell 11 Inside, the space inside the box inner shell 12 is the refrigerated space of the refrigerator, and this refrigerated space is the innermost end.

[0034] The box inner shell 12 is embedded in the box shell 11, and after the end of the box inner shell 12 is fixedly connected and sealed with the end of the box shel...

Embodiment 2

[0044] A refrigerator, comprising a main box shell, in which the above-mentioned box body structure with a vacuum insulation layer is connected. At least one set of the box structure of the vacuum insulation layer in each main box shell is provided, and a control main board is arranged in the main box shell.

Embodiment 3

[0046] A vacuum insulated refrigerator is provided with a vacuum box body and a vacuum box door, and the vacuum box door is composed of a box inner shell and a box outer shell. During processing, the inner surface of the box shell is covered with aluminum foil tape, and the outer surface of the box inner shell is covered with aluminum foil tape. The joint between the box inner shell and the box shell is designed as a U-shaped groove structure, and the two parts are connected together by welding to form a closed cavity. Supporting ribs for structural reinforcement are arranged between the inner shell of the box and the outer shell of the box body to ensure the structural strength of the vacuum box door.

[0047] The airtight box composed of the inner shell of the box and the outer shell of the box is evacuated to below 6Pa with a vacuum pump, and then the exhaust pipe is closed to form a vacuum airtight chamber.

[0048] The anti-dew pipe is placed in the annular groove of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com