Automatic mushroom culture cabin and mushroom culture method

A cultivation method and technology of mushrooms, applied in gardening methods, mushroom cultivation, botanical equipment and methods, etc., can solve the problems of low accuracy, inability to cover everything, poor timeliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

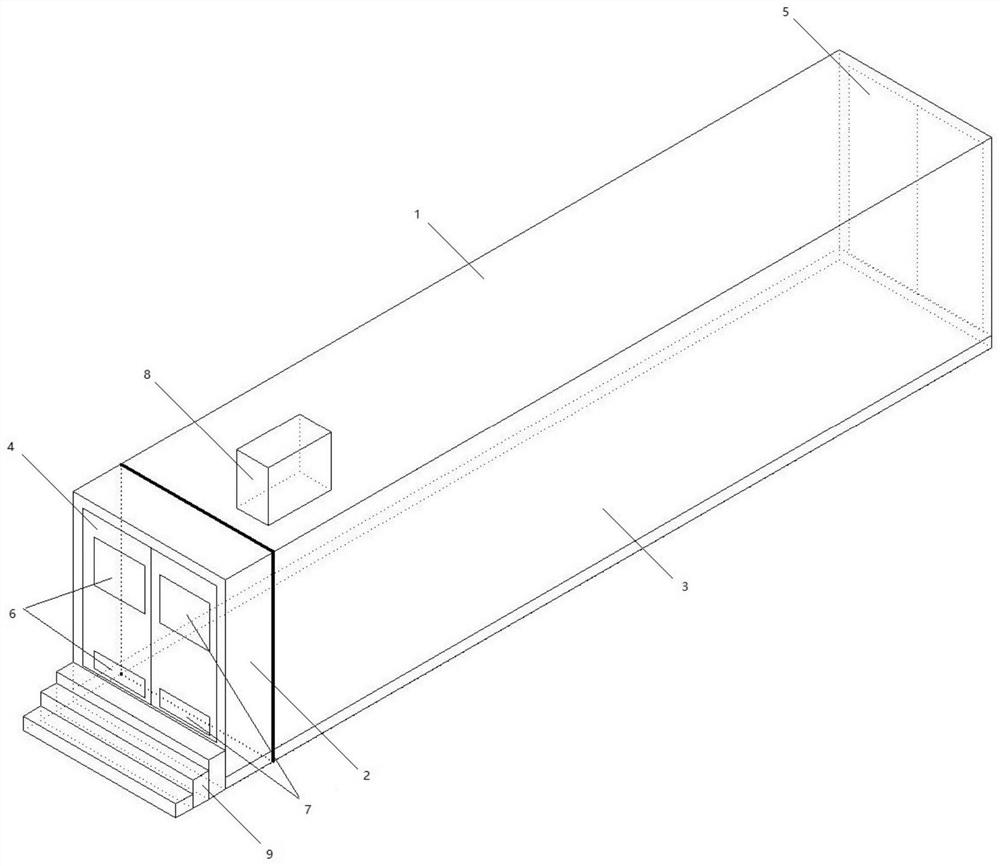

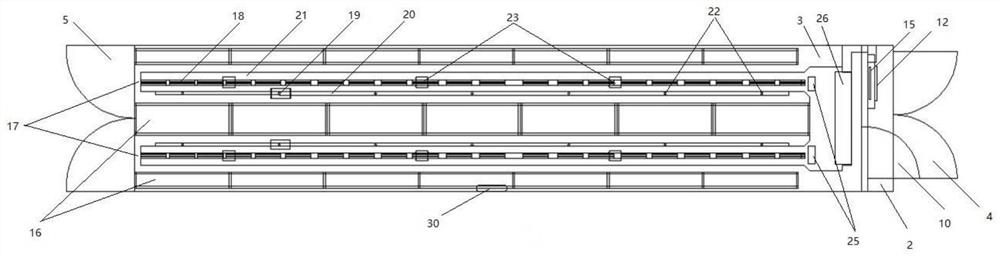

[0039] A kind of automated mushroom culture cabin, such as Figure 1~4 As shown, the training cabin body 1 is a cuboid, and its external dimensions are 12.2×2.4×2.9 meters. The inside of the cabin is divided into a smaller control room 2 and a larger training room 3, the control room is 2.2×0.5×2.6 meters, and the training room is 2.2×10.5×2.6 meters. Front hatch 4 and rear hatch 5 are respectively set at the front and rear ends of the cabin, nameplate 6 and ventilation grid 7 are set on the front hatch, compressor 8 is arranged at the top of the cabin, and the front end of the cabin is equipped with a movable stainless steel Step 9 facilitates access, and the user enters the control room through the front hatch.

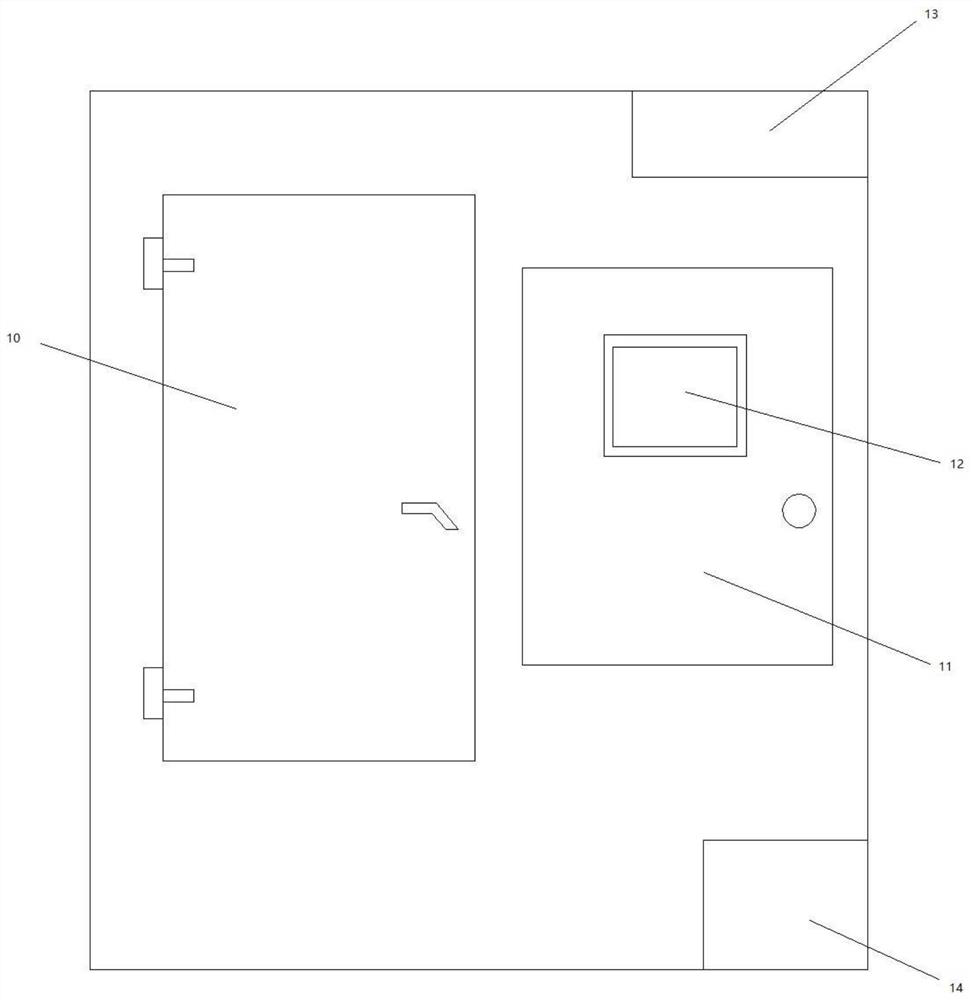

[0040] Such as figure 2 As shown, the left half of the control room is an internal closed door 10, the right half is a control cabinet 11, the upper right corner is provided with an air inlet 13, and the lower right corner is provided with an air outlet 14. A li...

Embodiment 2

[0054] A method for cultivating mushrooms, comprising a cold stimulation stage and a fruiting stage, wherein the mushroom bag is placed on the mushroom shelf of the automated mushroom cultivation cabin described in any one of claims 1-7 for cultivation to obtain mushrooms, and the cultivation It includes the following stages in order:

[0055] Stage 1: Cold stimulation stage, turn off the lights, control the culture chamber at a low temperature of 0-8°C, and keep it for one day;

[0056] Stage 2: In the fruiting stage, the temperature and light in the control cabin change according to certain rules to simulate the change of day and night. In a day and night, there are 12 to 18 hours of daytime and 6 to 12 hours of darkness. In this embodiment, the optional endpoint value of night time is 6 Hours, 12 hours or node value 8 hours, 10 hours; at the same time, maintain the humidity in the cabin between 85% and 95%, and the carbon dioxide concentration below 1000ppm for one week;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com