Control system of hair follicle extraction structure

A technology of controlling system and extracting structure, applied in the direction of control system, control/regulation system, control mechanical energy, etc., can solve the problems of unsatisfactory hair follicle extraction effect, hair follicle costing a lot of time and energy, and hair follicle accuracy reduction, etc. The requirements of technology and experience, the effect of few manual operation steps and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment discloses a control system for a hair follicle extraction structure, including an upper computer for controlling the hair follicle extraction structure, a control system I, a control system II, a control system III, and a control system IV.

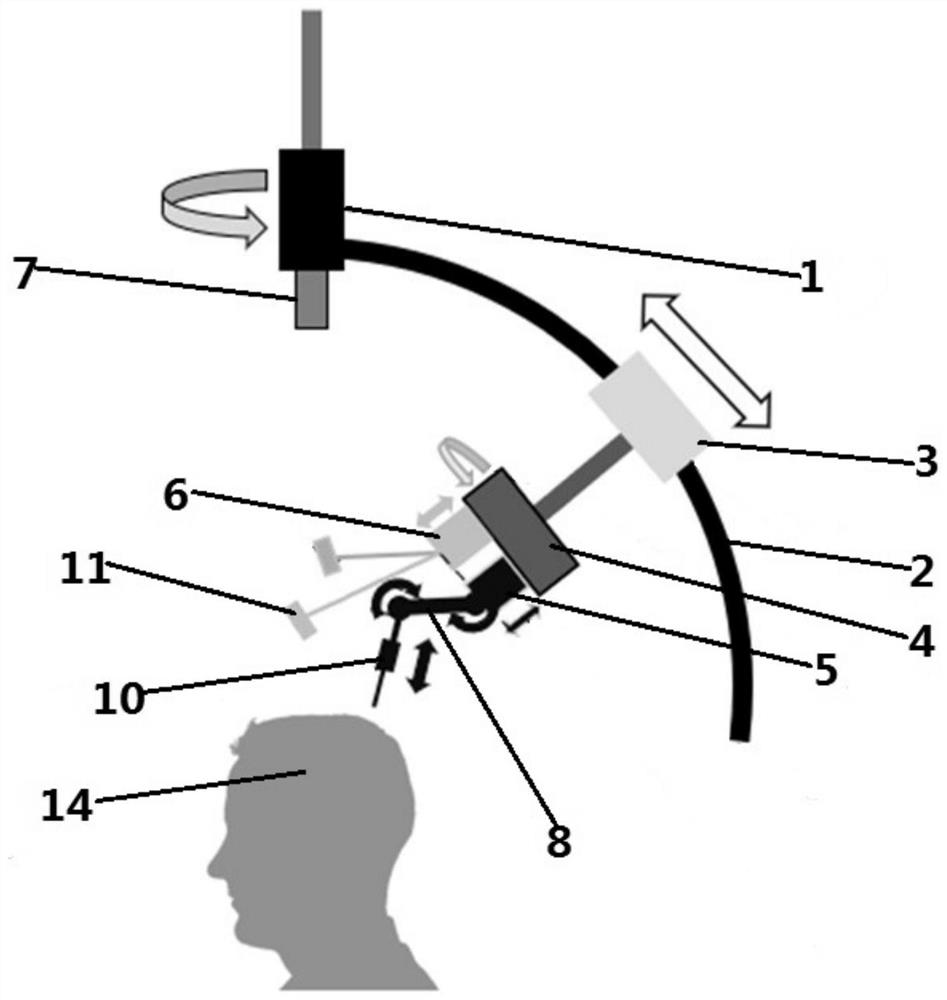

[0056] The hair follicle extraction structure includes a coarse adjustment screw 1, a sliding groove 2, a slider 3, a fine adjustment screw 4, a fine adjustment lifting part 5, an electron microscope lifting part 6, a binocular global camera 7, a connecting arm II 8, a cutter 10, and an electron microscope 11. . figure 1 The adjustment direction of each component is shown.

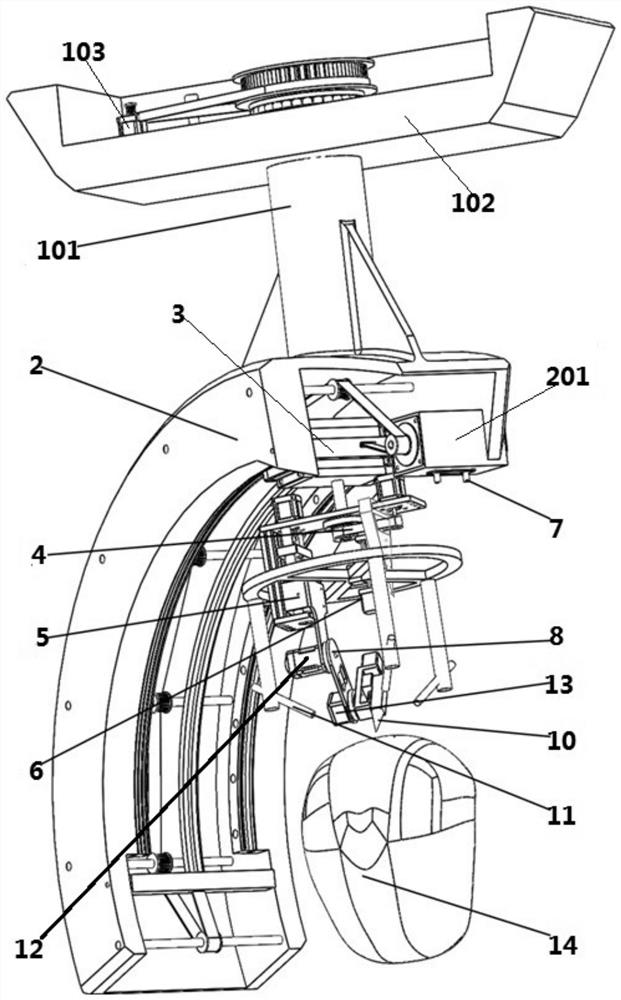

[0057] See figure 2 The coarse adjustment screw 1 includes a rotating rod 101, a platform 102 and a stepping motor I 103. The platform 102 is provided with a through hole I for the rotating rod 101 to pass through. The rotating rod 101 is vertically arranged, and the upper end of the rotating rod 101 passes through The through hole I on the platform...

Embodiment 2

[0085] This embodiment discloses a control system for a hair follicle extraction structure, including an upper computer for controlling the hair follicle extraction structure, a control system I, a control system II, a control system III, and a control system IV.

[0086] The hair follicle extraction structure includes a coarse adjustment screw 1, a sliding groove 2, a slider 3, a fine adjustment screw 4, a fine adjustment lifting part 5, an electron microscope lifting part 6, a binocular global camera 7, a connecting arm II 8, a cutter 10, and an electron microscope 11. .

[0087] See figure 2 The coarse adjustment screw 1 includes a rotating rod 101, a platform 102 and a stepping motor I 103. The platform 102 is provided with a through hole I for the rotating rod 101 to pass through. The rotating rod 101 is vertically arranged, and the upper end of the rotating rod 101 passes through The through hole I on the platform 102 extends out of the upper surface of the platform 102, and...

Embodiment 3

[0109] The main structure of this embodiment is the same as that of Embodiment 2. For further details, see Figure 8 The control system I also includes an encoder I and an encoder II, and the encoder I and the encoder II are respectively arranged on the stepper motor I103 and the stepper motor II201. The encoder I and the encoder II collect the rotation information of the stepper motor I103 and the stepper motor II201 respectively and send them to the single-chip microcomputer I, and the single-chip microcomputer I feeds back the rotation information to the upper computer.

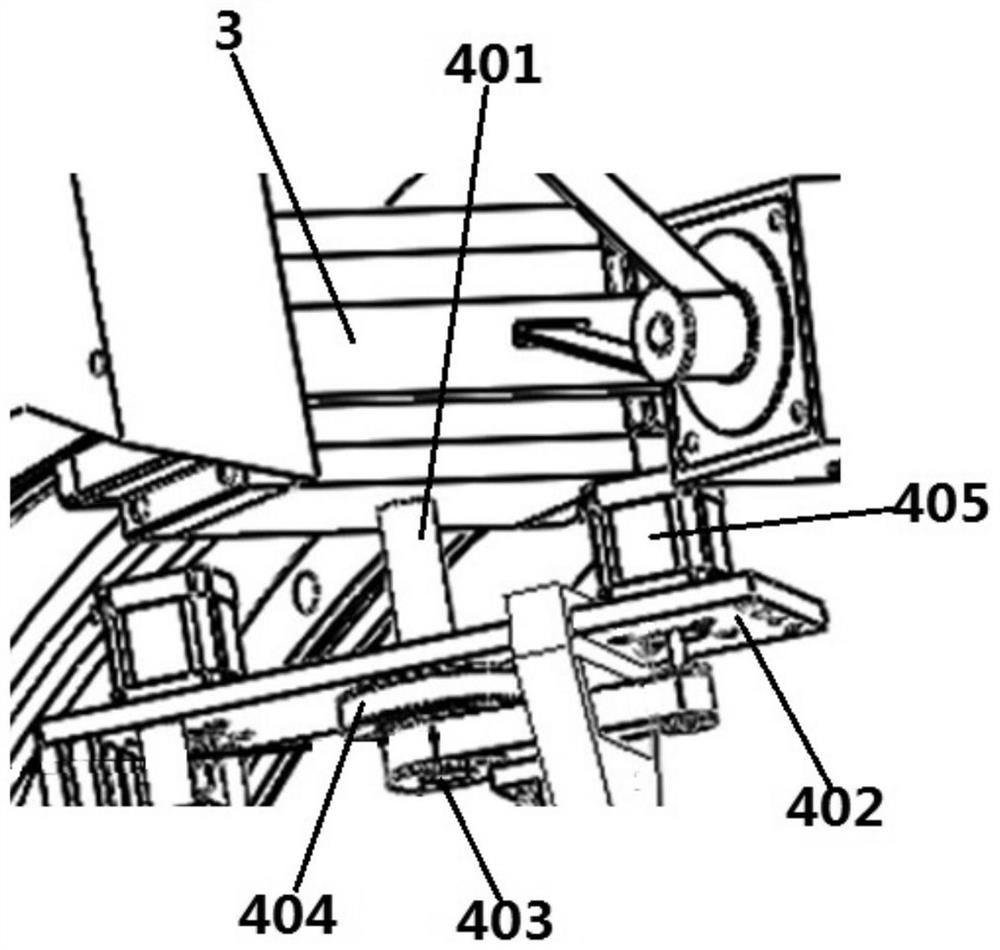

[0110] See Picture 9 The control system II also includes an encoder III and an encoder IV, and the encoder III and the encoder IV are respectively arranged on the stepper motor III405 and the stepper motor IV601. The encoder III and the encoder IV II collect the rotation information of the stepping motor III 405 and the stepping motor IV 601 respectively and send them to the single-chip microcomputer II, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com