Carbon nanotube and covalent organic framework compounded OER catalyst

A technology of covalent organic frameworks and carbon nanotubes, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor conductivity and achieve preparation The method is simple, easy to operate, and improves the effect of electron transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

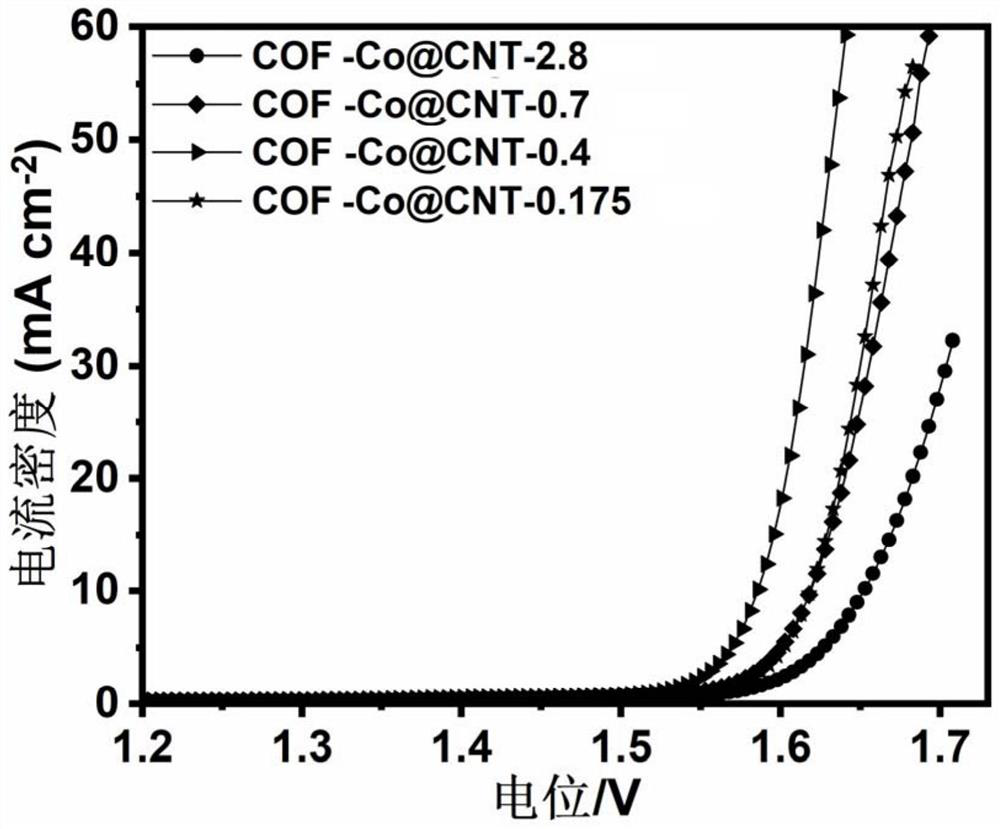

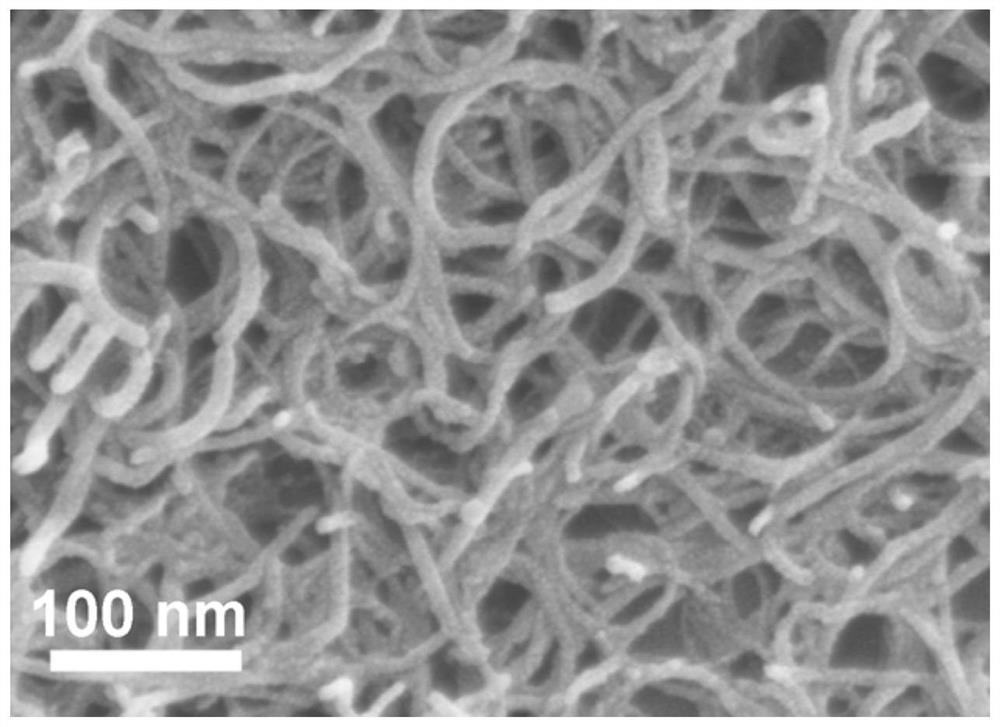

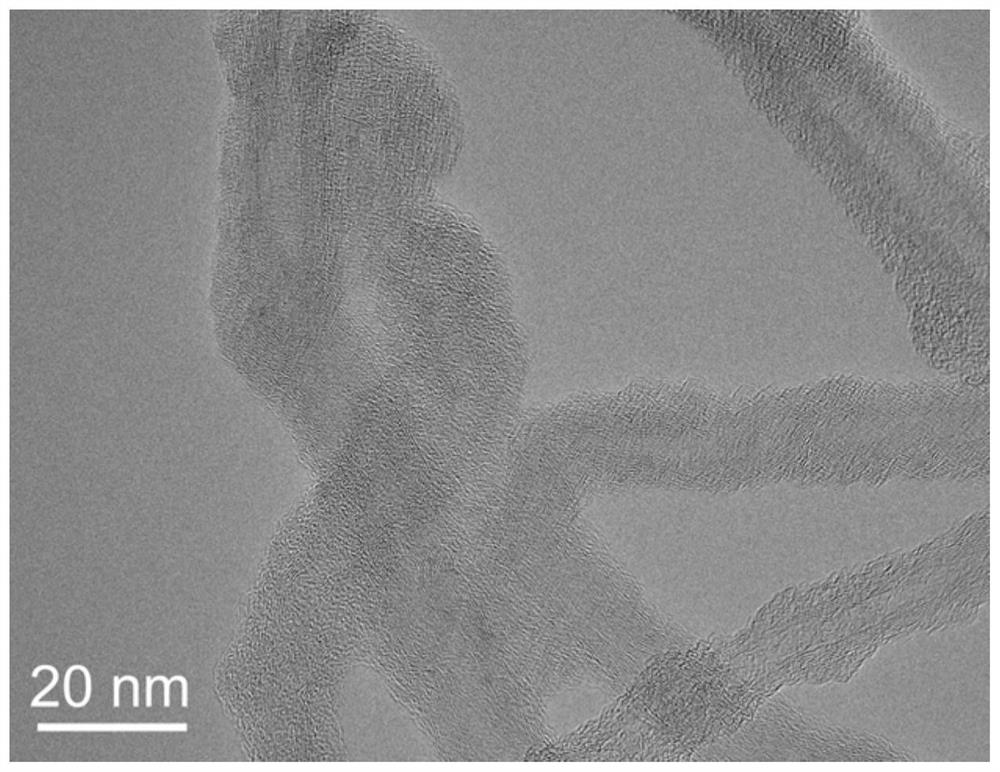

[0051] A method for preparing an OER catalyst composited with carbon nanotubes and a covalent organic framework, comprising the steps of:

[0052] (1) Take 3mg of carbon nanotubes and 6mg of 5,10,15,20-tetrakis(4-aminophenyl)porphyrin in a glass bottle and add 2mL of n-butanol / o-dichlorobenzene (volume ratio=1:1 ) mixed solution, ultrasonic (ultrasonic power is 200W) mixed for 30 minutes, then added 0.2mL3M acetic acid solution and continued ultrasonic for 5 minutes to obtain a mixed solution;

[0053] (2) Dissolve 2.4mg terephthalaldehyde in 400 microliters of n-butanol / o-dichlorobenzene (volume ratio=1:1) and ultrasonically homogenize to obtain a terephthalaldehyde solution; The diformaldehyde solution was slowly added dropwise to the mixed solution in step (1), and continued to sonicate for 20 minutes; then the mixed solution was transferred to a Pyrex glass bottle, and three times of freezing-vacuumizing-dissolving with liquid nitrogen and a double-row tube device process...

Embodiment 2

[0057] A method for preparing an OER catalyst composited with carbon nanotubes and a covalent organic framework, comprising the steps of:

[0058] (1) Take 3mg of carbon nanotubes and 1.5mg of 5,10,15,20-tetrakis(4-aminophenyl)porphyrin in a glass bottle and add 2mL of n-butanol / o-dichlorobenzene (volume ratio=1: 1) mixed solution, ultrasonic (ultrasonic power is 200W) mixed for 30 minutes, then added 0.2mL 3M acetic acid solution and continued ultrasonic for 5 minutes to obtain a mixed solution;

[0059] (2) 0.6mg terephthalaldehyde is dissolved in the mixed solution of n-butanol / o-dichlorobenzene (volume ratio=1:1) of 400 microliters and after ultrasonic homogenization, obtain terephthalaldehyde solution; The terephthalaldehyde solution is slowly added dropwise to the mixed solution in step (1), and the ultrasonic wave is continued for 20 minutes; then the mixed solution is transferred to a Pyrex glass bottle, and the liquid nitrogen and double-row tube device are used for t...

Embodiment 3

[0063] A method for preparing an OER catalyst composited with carbon nanotubes and a covalent organic framework, comprising the steps of:

[0064] (1) Take 3.5mg of carbon nanotubes and 1mg of 5,10,15,20-tetrakis(4-aminophenyl)porphyrin in a glass bottle and add 2mL of n-butanol / o-dichlorobenzene (volume ratio=1: 1) mixed solution, ultrasonic (ultrasonic power is 200W) mixed for 30 minutes, then added 0.2mL 3M acetic acid solution and continued ultrasonic for 5 minutes to obtain a mixed solution;

[0065] (2) 0.4mg terephthalaldehyde is dissolved in the mixed solution of n-butanol / o-dichlorobenzene (volume ratio=1:1) of 400 microliters and after ultrasonic homogenization, obtain terephthalaldehyde solution; The terephthalaldehyde solution is slowly added dropwise to the mixed solution in step (1), and the ultrasonic wave is continued for 20 minutes; then the mixed solution is transferred to a Pyrex glass bottle, and the liquid nitrogen and double-row tube device are used for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com