Preparation method and application of three-dimensional graphdiyne/Fe3O4 nano composite material

A nanocomposite material and graphdiyne technology, which is applied in the field of preparation of three-dimensional graphdiyne/Fe3O4 composite materials, achieves the effects of simple method, easy operation, high stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

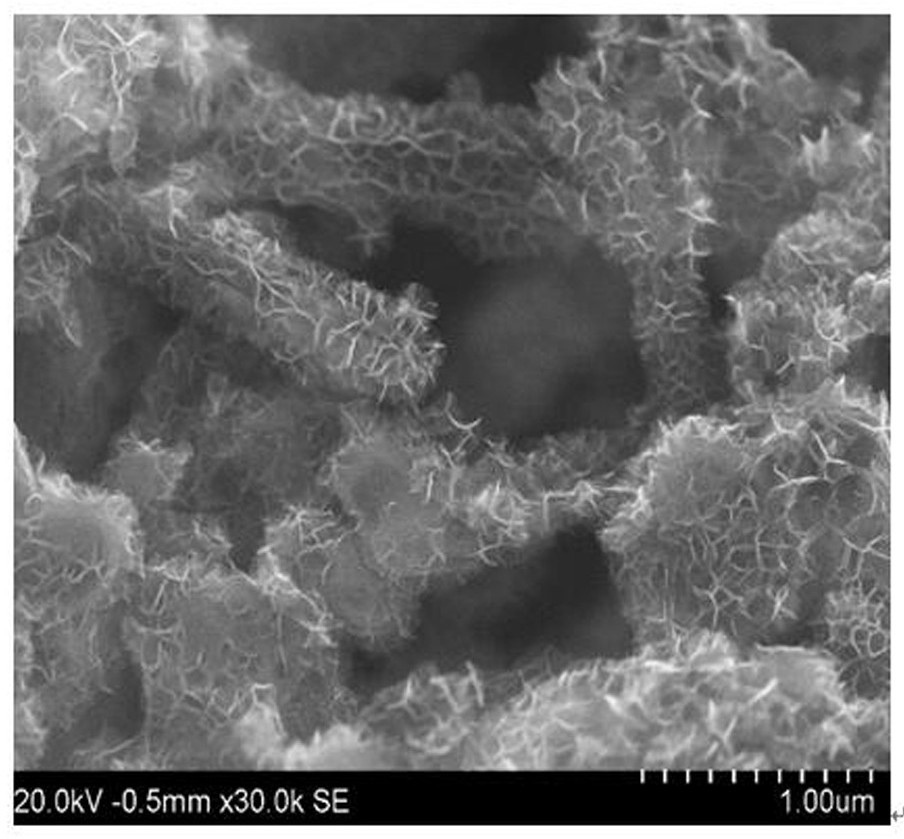

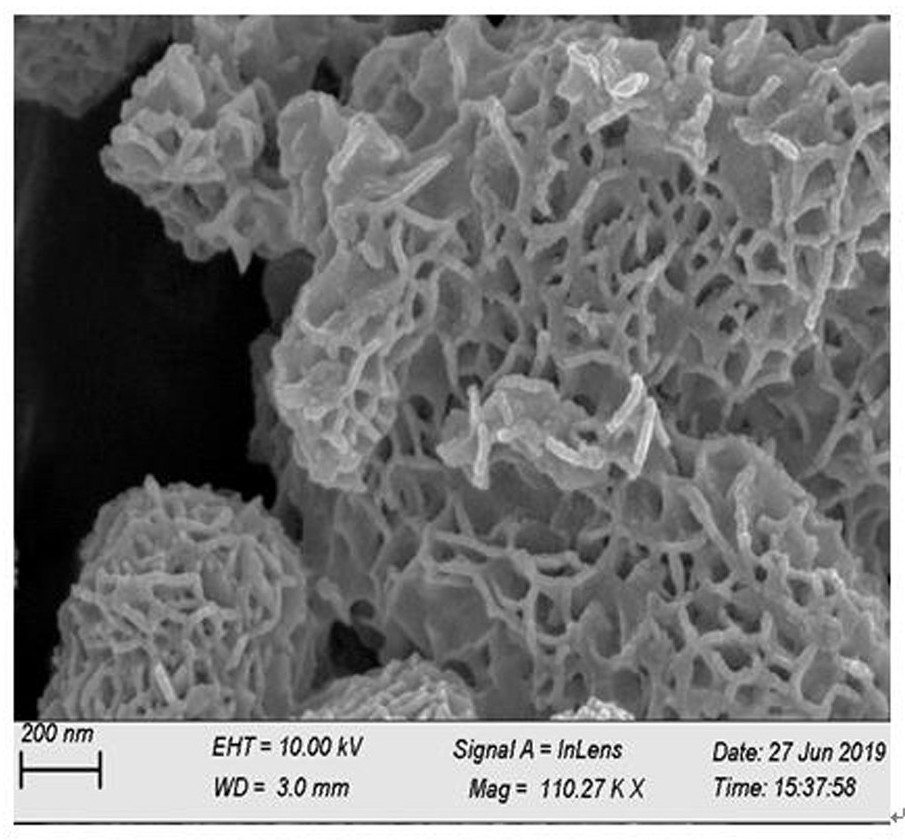

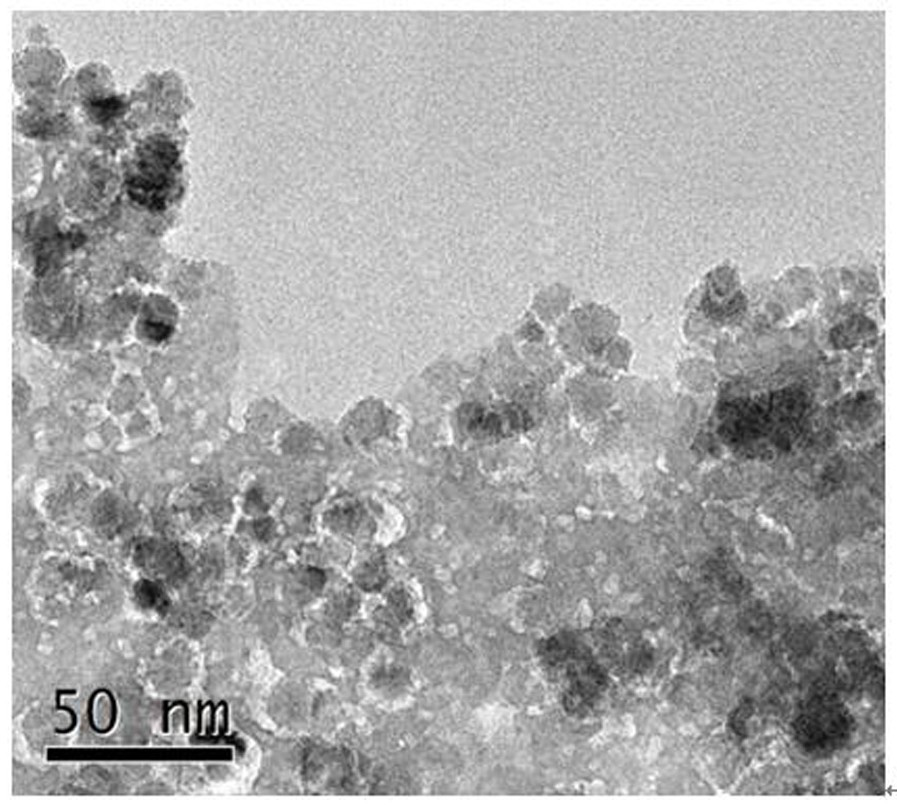

Image

Examples

Embodiment 1

[0025] (1) Treatment of graphyne nanotubes: Disperse 5 mg graphyne nanotubes in 5 mL concentrated H 2 SO 4 (98%), treated at 60°C for 6 hours, cooled with ice water, centrifuged at 12,000 rpm for 15 minutes to remove mixed acid, washed repeatedly with distilled water to make the clear liquid neutral, and finally centrifuged at 12,000 rpm Separate and dry in an oven at 80°C for 24 hours;

[0026] (2) Add 10 ml of 1.0 mmol / L FeCl 3 and 0.5 mmol / L FeCl 2 The mixed solution was placed in a 50 ml three-necked flask and stirred vigorously under nitrogen protection. After thorough mixing, 5.0 mg of GDY treated in step (1) was dispersed in the above solution and stirred continuously for 30 minutes. The solution was incubated at 35°C, and then aqueous ammonia was added dropwise to adjust the pH value of the solution to 8.5. After continuing to stir the mixed solution for one hour, the temperature was raised rapidly, and the stirring reaction was continued at a constant temperature ...

Embodiment 2

[0033] (1) Treatment of graphyne nanotubes: Weigh 10 mg graphyne and disperse in 8 mL concentrated HNO at 1:3 3 (68%), and H 2 SO 4 (98%) and the mixture, treated at 80°C for 8 hours, cooled with ice water, centrifuged at 14,000 rpm for 10 min at high speed, after acid removal, washed repeatedly with distilled water until the clear liquid was neutral, and finally 14,000 rpm Centrifuge and dry in an oven at 80°C for 24 hours;

[0034] (2) Add 10 ml of 3.0 mmol / L FeCl 3 and 1.0 mmol / L FeCl 2 The mixed solution was placed in a 25 ml three-necked flask and stirred vigorously under nitrogen protection. After thorough mixing, 10.0 mg of GDY treated in step (1) was dispersed in the above solution and stirred continuously for 30 minutes. The solution was kept warm at 45°C, and then a mixed base of concentrated ammonia water with a volume ratio of 1:1 and 2.5 mol / L NaOH was added dropwise to adjust the pH value of the solution to 10.0. After continuing to stir the mixed solution f...

Embodiment 3

[0036] (1) Treatment of graphyne nanotubes: Weigh 20 mg graphyne and disperse in 20 mL concentrated HNO at 1:2 3 (68%), and H 2 SO 4 (98%) and the mixture, treated at 70°C for 5 hours, cooled with ice water, centrifuged at 14000 rpm for 20min at high speed, after acid removal, washed repeatedly with distilled water until the clear liquid was neutral, and finally 14000 rpm Centrifuge and dry in an oven at 80°C for 24 hours;

[0037] (2) Add 20 ml of 2.0 mmol / L FeCl 3 and 1.0 mmol / L FeCl 2 The mixed solution was placed in a 50 ml three-necked flask and stirred vigorously under nitrogen protection. After thorough mixing, 15 mg of GDY treated in step (1) was dispersed in the above solution and stirred continuously for 30 minutes. The solution was kept warm at 45°C, and then a mixed base of concentrated ammonia water with a volume ratio of 3:1 and 1.0 mol / L KOH was added dropwise to adjust the pH value of the solution to 10.0. After continuing to stir the mixed solution for on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com