High-plasticity cement product doped with iron ore dressing tailing powder and preparation method of high-plasticity cement product

A cement product, high plasticity technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of limited transportation distance, low added value, and low utilization rate of iron beneficiation tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

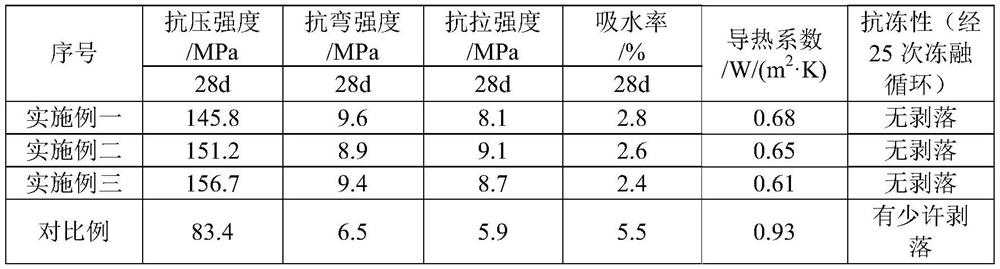

Examples

Embodiment 1

[0026] This embodiment provides a high-plasticity cement product mixed with iron-selection tailings powder, which consists of the following components in terms of parts by mass: kiln dust: 18 parts; dihydrate gypsum: 17 parts; chalk: 30 parts; Clay: 55 parts; Diatomite: 4 parts; Iron tailings: 12 parts; Concrete with fiber: 8 parts; Ceramic micropowder: 12 parts; Grinding aid: 1 part.

[0027] Above-mentioned a kind of preparation method of the high plasticity cement product that is mixed with iron-selection tailings powder comprises the following steps:

[0028] (1) Mix kiln dust, chalk, clay, and correction materials together to obtain a mixed raw material with a particle diameter of 20-22mm. Use a dryer to dry the mixed raw material. The moisture content in the mixed raw material is controlled at 1-22 mm. 1.5%;

[0029] (2) Send the above-mentioned dried mixed raw materials and grinding aids into a raw meal mill to prepare mixed powder, and the particle size of the mixed p...

Embodiment 2

[0034] This embodiment provides a high plasticity cement product mixed with iron-selection tailings powder, which consists of the following components in terms of parts by mass: kiln dust: 12 parts; dihydrate gypsum: 20 parts; chalk: 35 parts; Clay: 40 parts; Bauxite: 7 parts; Iron tailings: 11 parts; Concrete with fiber: 12 parts; Ceramic micropowder: 15 parts; Grinding aid: 2 parts.

[0035] Above-mentioned a kind of preparation method of the high plasticity cement product that is mixed with iron-selection tailings powder comprises the following steps:

[0036] (1) Mix kiln dust, chalk, clay, and correction materials together to obtain a mixed raw material with a particle diameter of 20-24 mm. Use a dryer to dry the mixed raw material. The moisture content in the mixed raw material is controlled at 1-24 mm. 1.8%;

[0037] (2) Send the above-mentioned dried mixed raw materials and grinding aids into a raw meal mill to prepare mixed powder, and the particle size of the mixed ...

Embodiment 3

[0042] This embodiment provides a high plasticity cement product mixed with iron-selection tailings powder, which consists of the following components in terms of parts by mass: kiln dust: 15 parts; dihydrate gypsum: 15 parts; chalk: 20 parts; Clay: 50 parts; siltstone: 8 parts; iron tailings: 10 parts; concrete with fiber: 6 parts; ceramic powder: 7 parts; grinding aid: 2 parts.

[0043] Above-mentioned a kind of preparation method of the high plasticity cement product that is mixed with iron-selection tailings powder comprises the following steps:

[0044] (1) Mix kiln dust, chalk, clay, and correction materials together to obtain a mixed raw material with a particle diameter of 20-25mm. Use a dryer to dry the mixed raw material. The moisture content in the mixed raw material is controlled at 1.2- 2%;

[0045] (2) Send the above-mentioned dried mixed raw materials and grinding aids into a raw meal mill to prepare mixed powder, and the particle size of the mixed powder is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com