Mixed steel slag coal-based columnar formed active coke for low-temperature flue gas denitrification and preparation method thereof

A technology of low-temperature flue gas and active coke, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high cost and low efficiency, and achieve the effects of improving ignition point, reducing production cost and improving denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

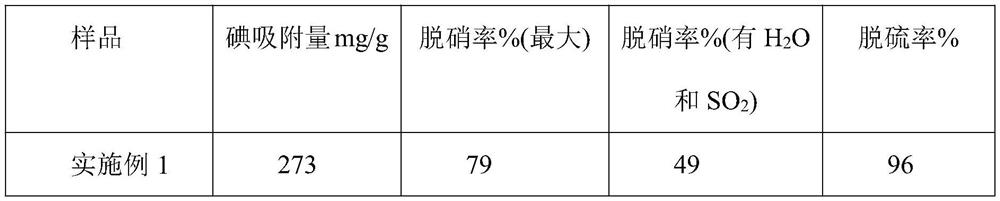

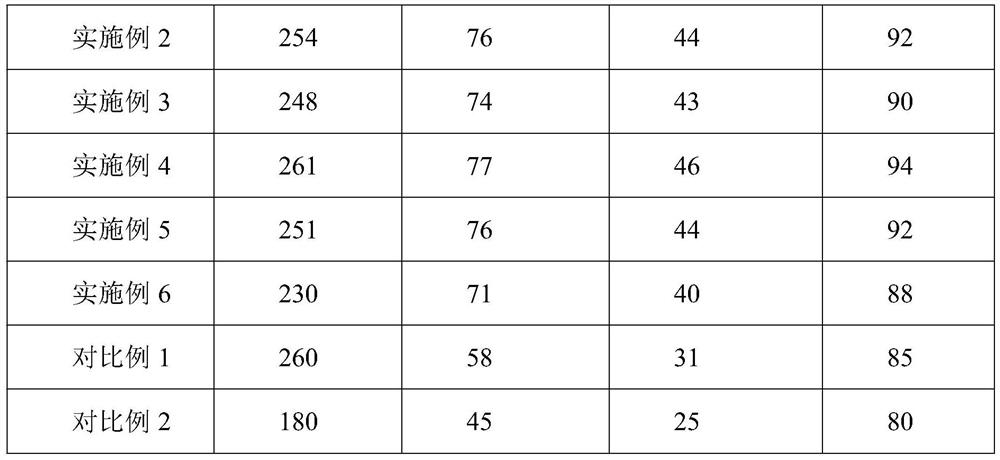

Examples

Embodiment 1

[0028] Take the components and mass proportions of preparing 200 grams of the product of the present invention as an example:

[0029] Crush the steel slag and lignite into 3-8mm materials and wash them with deionized water, put them in a drying box and dry them at 105°C for 6 hours; use a planetary ball mill to grind the coal and steel slag for 30 minutes at 400r / min, Then grind for 30 minutes under the condition of 600 r / min; more than 95% of the ground coal powder and steel slag pass through a 200-mesh standard sampling sieve.

[0030] Fully mix 180g of coal powder and 20g of steel slag powder, that is, steel slag accounts for 10%. Add 125g of coal tar, 55g of glycerin and 70g of water and fully stir and knead, process the powder into a paste with better plasticity and then carry out extrusion molding. The prepared columnar active coke precursor was naturally air-dried at room temperature for 30 minutes; then the active coke precursor was dried in a drying oven at 155°C fo...

Embodiment 2

[0035] Take the components and mass proportions of preparing 200 grams of the product of the present invention as an example:

[0036] Crush the steel slag and lignite into 3-8mm materials and wash them with deionized water, put them in a drying box and dry them at 105°C for 6 hours; use a planetary ball mill to grind the coal and steel slag for 30 minutes at 400r / min, Then grind for 30 minutes under the condition of 600 r / min; more than 95% of the ground coal powder and steel slag pass through a 200-mesh standard sampling sieve.

[0037] Fully mix 180g of coal powder and 20g of steel slag powder, that is, steel slag accounts for 10%. Add 125g of coal tar, 55g of glycerin and 70g of water and fully stir and knead, process the powder into a paste with better plasticity and then carry out extrusion molding. The prepared columnar active coke precursor was naturally air-dried at room temperature for 30 minutes; then the active coke precursor was dried in a drying oven at 155°C fo...

Embodiment 3

[0042] Take the components and mass proportions of preparing 200 grams of the product of the present invention as an example:

[0043] Crush the steel slag and lignite into 3-8mm materials and wash them with deionized water, put them in a drying box and dry them at 105°C for 6 hours; use a planetary ball mill to grind the coal and steel slag for 30 minutes at 400r / min, Then grind for 30 minutes under the condition of 600 r / min; more than 95% of the ground coal powder and steel slag pass through a 200-mesh standard sampling sieve.

[0044] Fully mix 180g of coal powder and 20g of steel slag powder, that is, steel slag accounts for 10%. Add 125g of coal tar, 55g of glycerin and 70g of water and fully stir and knead, process the powder into a paste with better plasticity and then carry out extrusion molding. The columnar active coke precursor was naturally air-dried at room temperature for 30 minutes; then the active coke precursor was dried in a drying oven at 155°C for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com