Supersulfide phosphogypsum phosphorus slag cement concrete product and preparation method thereof

A technology for cement concrete and phosphogypsum, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cement content and low utilization rate of phosphogypsum, and achieves improved strength and shortened setting time. , the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below.

[0023] A preparation method of phosphorous gypsum phosphorous slag cement concrete products, the steps are as follows:

[0024] S1. Phosphorus slag grinding: wet-grind phosphorus slag with water until the specific surface area is 481.2m 2 / kg to obtain a solid content of 57.3% phosphorus slag slurry for subsequent use.

[0025] S2. Grinding of phosphogypsum: add 1% ordinary Portland cement to phosphogypsum, add water and wet grind until the specific surface area is 413.5m 2 / kg to obtain phosphogypsum slurry with a solid content of 57.5%, for subsequent use.

[0026] S3. Filtration and concentration: the phosphorus slag slurry and phosphogypsum slurry are filtered and concentrated to obtain phosphorus slag sludge and 77.6% phosphogypsum slurry with a solid content of 78.2%, which are set aside.

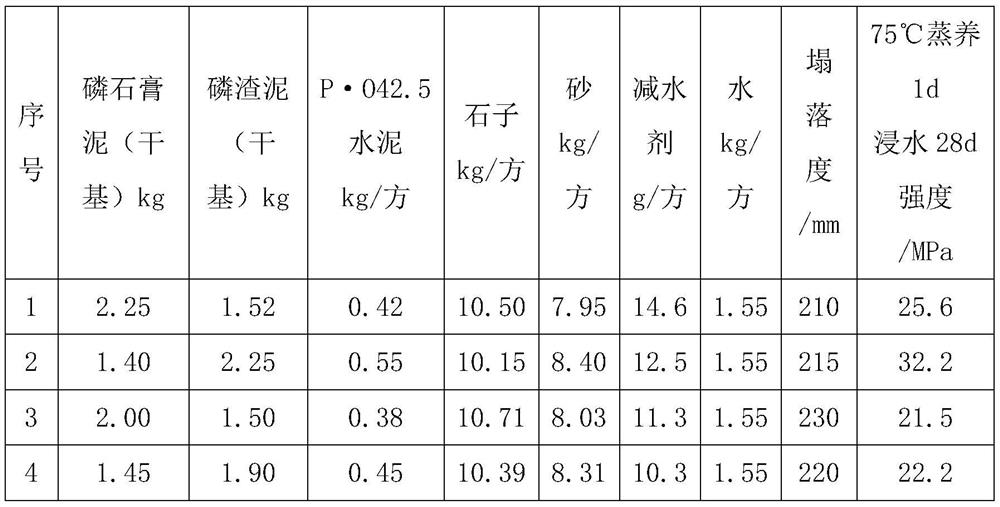

[0027] S4. Mixing and mixing: add phosphogypsum mud, phosphorus slag mud, ordinary Portland...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com