Super-wear-resistant long-acting antibacterial and antiviral nano-coating and preparation method thereof

A nano-coating, anti-virus technology, applied in anti-fouling/underwater coatings, alkali metal silicate coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

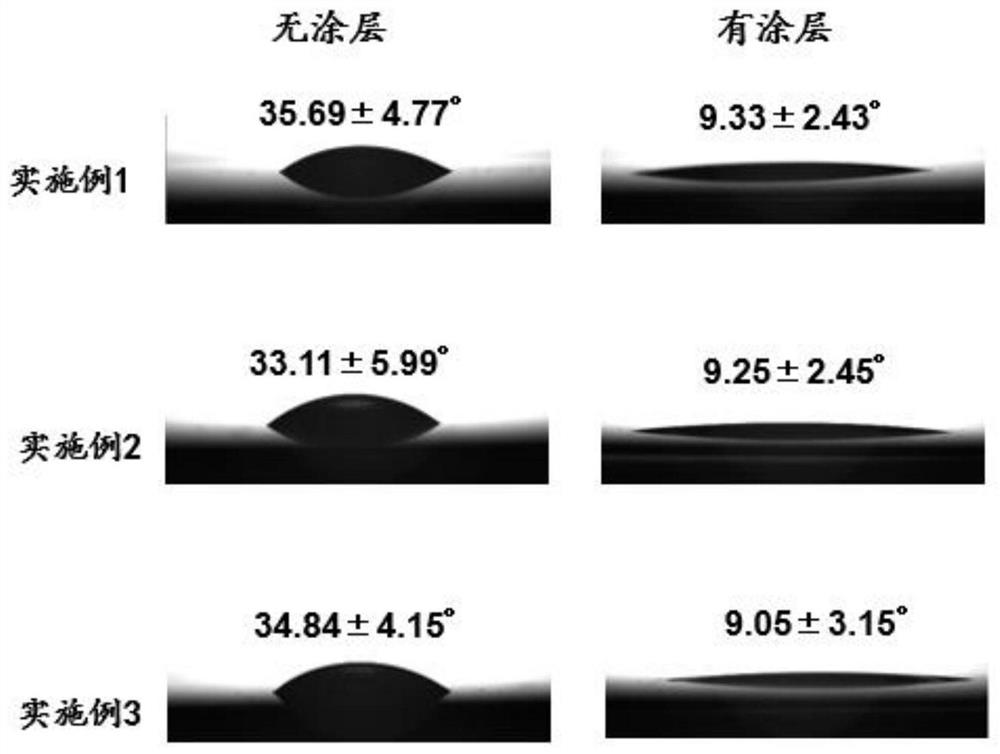

Embodiment 1

[0038] First add 150 parts of deionized water to the beaker, add 1 part of EK 50 and 1 part of silver nitrate at a speed of 300 rpm, and continue stirring for 5 minutes; add 15 parts of lithium silicate at a speed of 400 rpm , continue stirring for 10 minutes; increase the speed to 500 rpm, add 15 parts of potassium silicate, and continue stirring for 10 minutes; add 1 part of TEGO 2000; add 1 part of silicone defoamer, 1 part of poly Methylsiloxane leveling agent, continue to stir for 10 minutes, and finally get super wear-resistant long-lasting antibacterial and antiviral nano-coating.

[0039] The paint is used as follows:

[0040] (1) Stir well before use, filter with a 400-mesh filter, and apply air precision spraying on glass sheets or stainless steel sheets with a coating thickness of 50 microns;

[0041] (2) Bake at 50°C for 10 minutes and at 180°C for 30 minutes.

Embodiment 2

[0043] First add 200 parts of deionized water to the beaker, add 3 parts of EK 50 and 3 parts of silver nitrate at a speed of 300 rpm, and continue stirring for 5 minutes; add 20 parts of silicic acid at a speed of 400 rpm Lithium, continue to stir for 10 minutes; increase the speed to 500 rpm, add 35 parts of potassium silicate, continue to stir for 10 minutes; add 1.5 parts of TEGO 2000; add 2 parts of polyether modified silicone foaming agent, 2 parts of organically modified polydimethylsiloxane leveling agent, continue to stir for 10 minutes, and finally get a super wear-resistant long-lasting antibacterial and antiviral nano-coating.

[0044] The using method of coating is identical with embodiment 1.

Embodiment 3

[0046] First add 250 parts of deionized water to the beaker, add 3 parts of EK 50 and 2 parts of silver nitrate at a speed of 300 rpm, and continue stirring for 5 minutes; add 20 parts of lithium silicate at a speed of 400 rpm , continue to stir for 10 minutes; increase the speed to 500 rpm, add 30 parts of potassium silicate, and continue to stir for 10 minutes; add 2 parts of TEGO 2000; add 2 parts of silicone defoamer, 2 parts of poly Methylsiloxane leveling agent, continue to stir for 10 minutes, and finally get super wear-resistant long-lasting antibacterial and antiviral nano-coating.

[0047] The using method of coating is identical with embodiment 1.

PUM

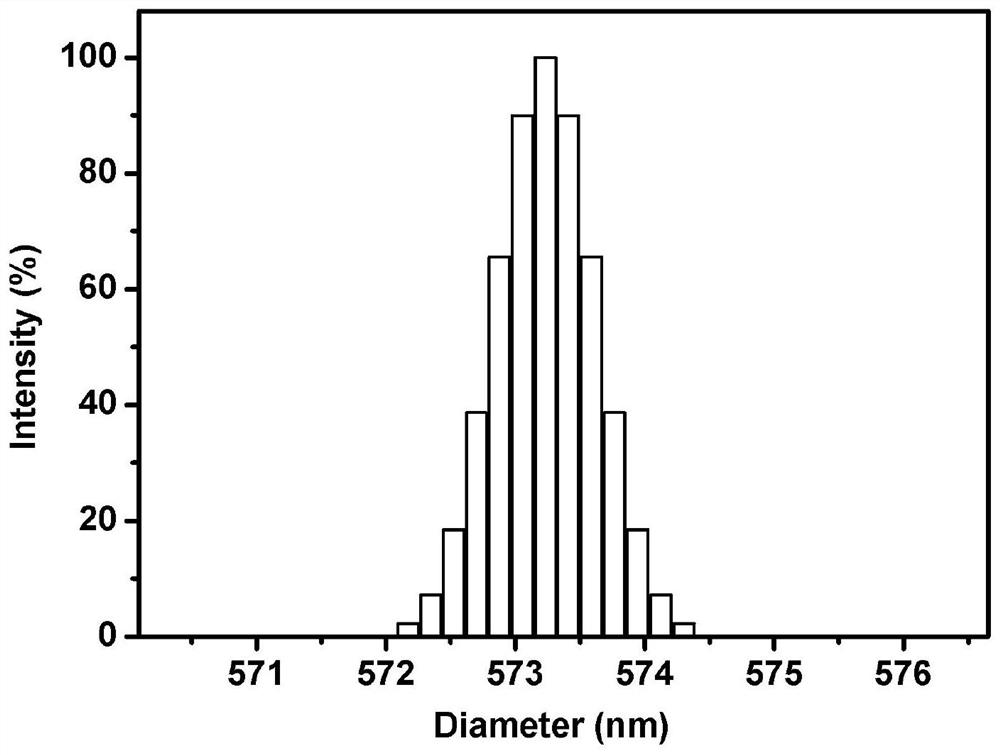

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com