Large-scale preparation and patterning method of two-dimensional material semiconductor film and two-dimensional material semiconductor film

A technology for large-scale preparation of two-dimensional materials, applied in the field of two-dimensional semiconductor thin film preparation, can solve the problems of inability to apply roll-to-roll technology, low resolution and precision, and uneven stacking of nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

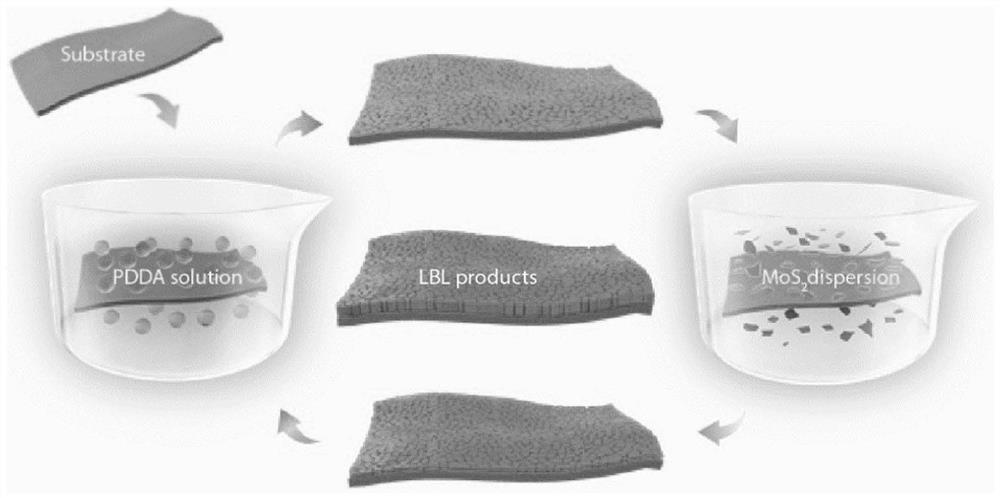

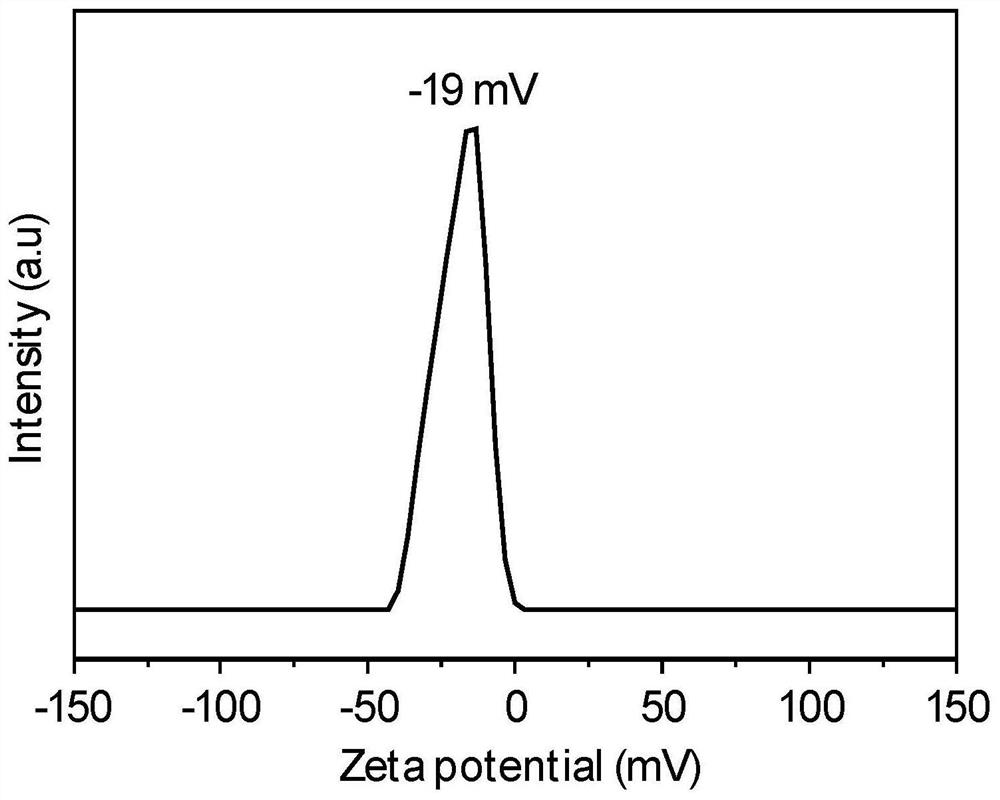

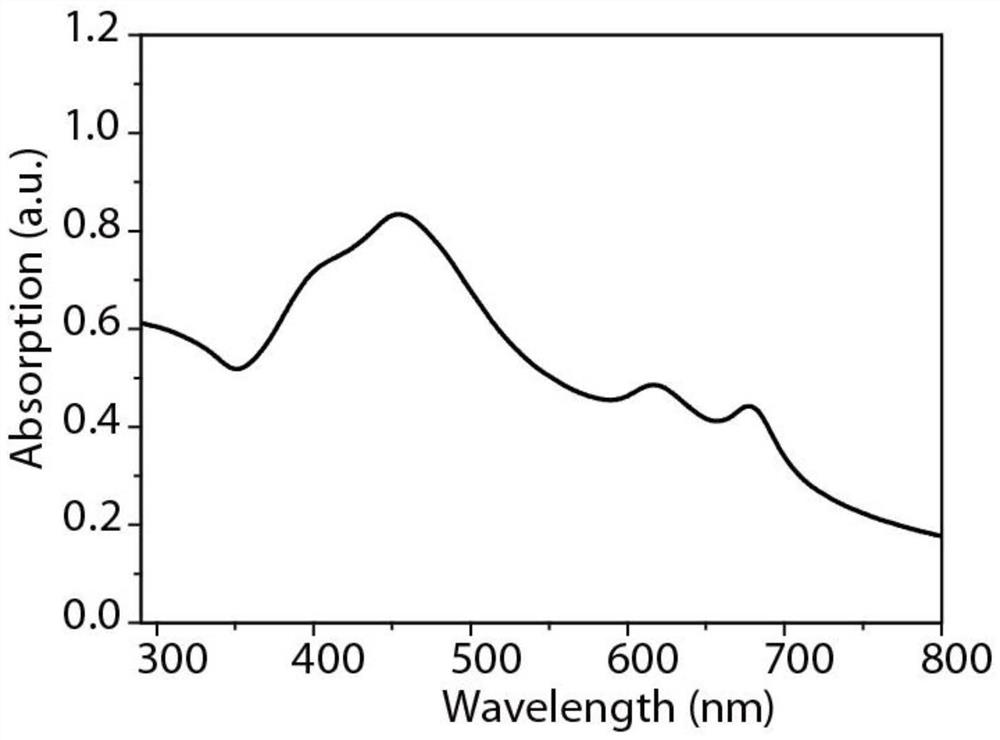

[0045] The invention discloses a large-scale preparation and patterning method of a two-dimensional material semiconductor thin film, comprising the following steps:

[0046] Step 1, pre-treat the substrate, the substrate can be rigid SiO 2 / Si or glass sheet, or flexible PET or PI, the specific operation is to ultrasonicate the substrate in acetone and isopropanol for 5 minutes, and then treat the substrate with oxygen plasma (120w, 5min).

[0047] Step 2, use a negative photolithography target pattern on the pretreated substrate: the specific operation is to spin coat the photoresist on the substrate (4000rpm, 30s); treat the substrate on a heating plate at 150°C for 1min; place the substrate on Under the mask plate of the target pattern of the lithography machine, expose it to a UV lamp for 10s; treat the substrate on a heating plate at 100°C for 1min; develop the substrate in the developer for 12s, clean the developer on the substrate with distilled water and dry it with a...

Embodiment 2

[0051] The solution self-assembly preparation and patterning method disclosed in the present invention can also be extended to other charged two-dimensional semiconductor materials, such as In 2 Se 3 two-dimensional semiconductor.

[0052] Step 1, pre-treat the substrate, the substrate can be rigid SiO 2 / Si or glass sheet, or flexible PET or PI, the specific operation is to ultrasonicate the substrate in acetone and isopropanol for 5 minutes, and then treat the substrate with oxygen plasma (120w, 5min).

[0053] Step 2, use a negative photolithography target pattern on the pretreated substrate: the specific operation is to spin coat the photoresist on the substrate (4000rpm, 30s); treat the substrate on a heating plate at 150°C for 1min; place the substrate on Under the mask plate of the target pattern of the lithography machine, expose it to a UV lamp for 10s; treat the substrate on a heating plate at 100°C for 1min; develop the substrate in the developer for 12s, clean th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com