Junction Gate-Drain Power Devices

A leakage power and junction gate technology, applied in the field of microelectronics, can solve the problems of increasing device difficulty, high manufacturing cost, and reducing device yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

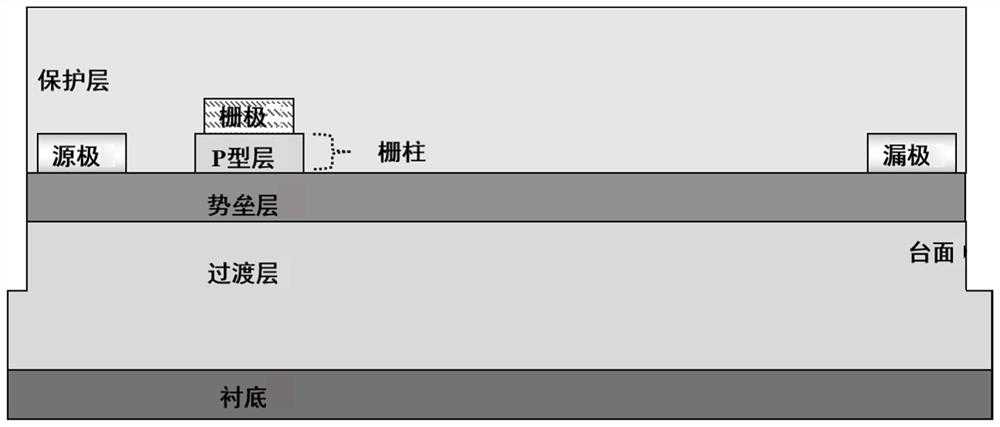

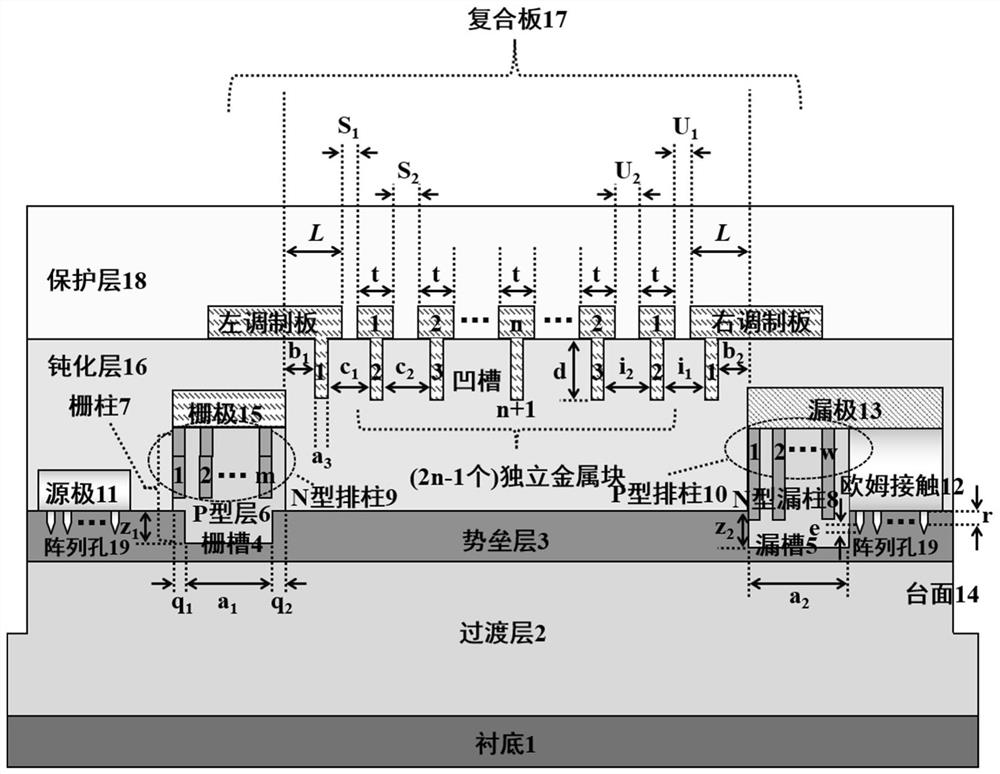

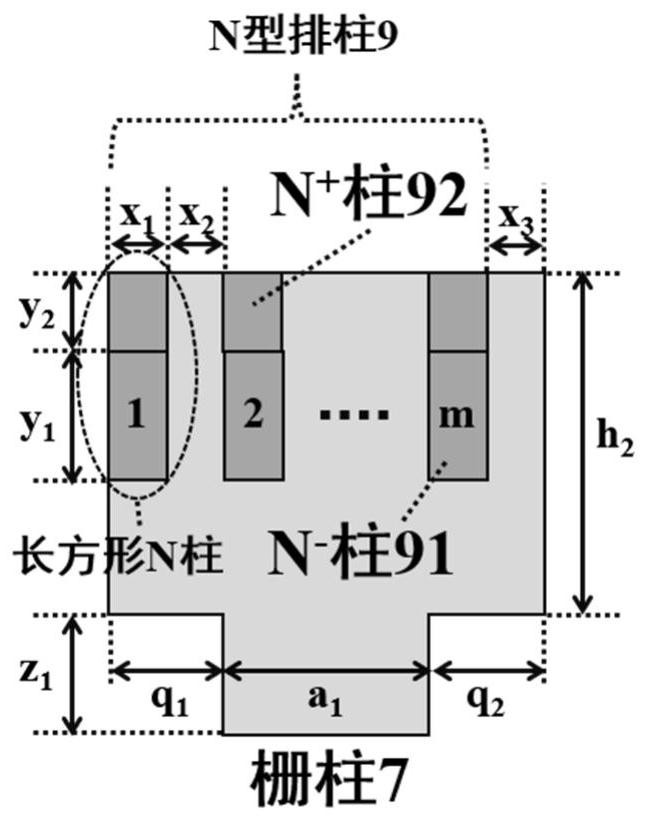

[0104] Embodiment 1: Making the thickness h of the P-type layer 6 above the barrier layer 3 2 20nm, the doping concentration of P-type layer 6 is 5×10 20 cm -3 , the length of gate column 7 is 4nm, and the doping concentration of N-type drain column 8 is 5×10 20 cm -3 , which lies at a thickness h above the barrier layer 3 1 is 10nm, and the depth of the P-type column 10 is u 1 7nm, doping concentration is 5×10 20 cm -3 , the number w of rectangular P columns is 1, N - column 91 depth y 1 10nm, doping concentration is 1×10 18 cm -3 , N + Depth y of column 92 2 8nm, doping concentration is 5×10 20 cm -3 , the number m of rectangular N columns is 1, the array hole 19 is composed of 2×2 holes of the same size, the number of grooves is 3, and the number of independent metal blocks is 1 junction gate-drain power device.

[0105] Step 1. Epitaxial GaN material is made transition layer 2 on sapphire substrate 1, as Figure 8 a.

[0106] 1a) GaN material with a thickne...

Embodiment 2

[0155] Embodiment 2: Making the thickness h of the P-type layer 6 above the barrier layer 3 2 200nm, the doping concentration of P-type layer 6 is 1×10 19 cm -3 , the length of gate column 7 is 1800nm, and the doping concentration of N-type drain column 8 is 5×10 19 cm -3 , which lies at a thickness h above the barrier layer 3 1 is 200nm, and the depth of the P-type column 10 is u 1 80nm, doping concentration is 1×10 19 cm -3 , the number w of rectangular P columns is 3, N - column 91 depth y 1 100nm, doping concentration 1×10 17 cm -3 , N + Depth y of column 92 2 80nm, doping concentration is 5×10 19 cm -3 , the number m of rectangular N pillars is 3, the array hole 19 is composed of 5×5 holes of the same size, the number of grooves is 5, and the number of independent metal blocks is 3 junction gate-drain power devices.

[0156] Step 1. Epitaxially AlN and GaN materials on the silicon carbide substrate 1 to form the transition layer 2, such as Figure 8 a.

[...

Embodiment 3

[0192] Embodiment 3: Making the thickness h of the P-type layer 6 above the barrier layer 3 2 400nm, the doping concentration of P-type layer 6 is 5×10 16 cm -3 , the length of gate column 7 is 5000nm, and the doping concentration of N-type drain column 8 is 1×10 16 cm -3 , which lies at a thickness h above the barrier layer 3 1 is 600nm, and the depth of the P-type column 10 is u 1 550nm, doping concentration is 1×10 16 cm -3 , the number w of rectangular P columns is 5, N - column 91 depth y 1 50nm, doping concentration is 1×10 11 cm -3 , N + Depth y of column 92 2 300nm, doping concentration is 1×1018 cm -3 , the number m of rectangular N pillars is 5, the array hole 19 is composed of 10×10 holes of the same size, the number of grooves is 7, and the number of independent metal blocks is 5 junction gate-drain power devices.

[0193] Step A. Epitaxial AlN and GaN materials on the silicon substrate 1 from bottom to top to make the transition layer 2, such as Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com