Power battery and battery cloud platform management method

A technology for power batteries and battery casings, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of irreparable batteries, and achieve the effects of increasing battery safety performance, easy implementation, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

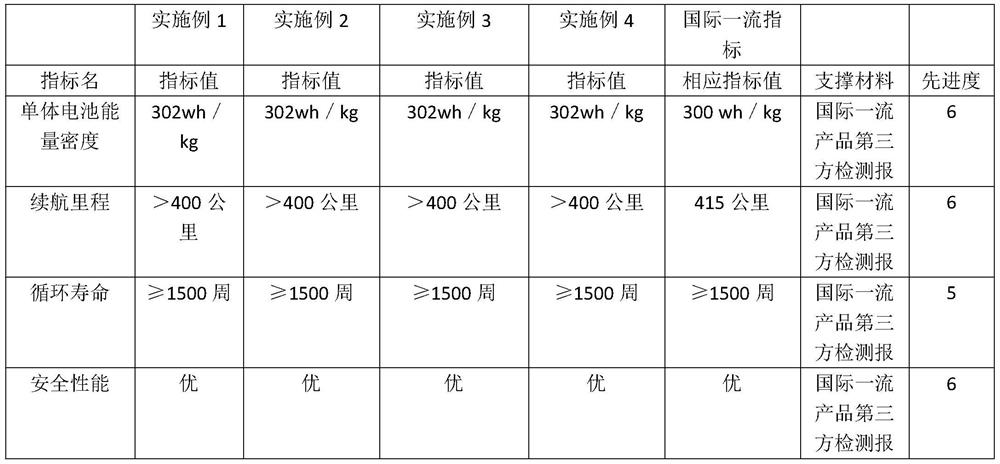

Examples

Embodiment 1

[0034] 1. A power battery, comprising a battery casing, an electrode group and an electrolyte coated in the battery casing; the electrode group is formed by laminating a plurality of positive and negative electrode sheets and a diaphragm; it is characterized in that the positive electrode sheet is coated with The high-nickel positive electrode material composition of the cloth, by weight percentage, in the positive electrode material composition, binder 1-2.5%; Conductive agent 2.5-4%, the balance is high-nickel positive electrode active material; Silicon coated on the negative plate The base negative electrode material composition is calculated by weight percentage. In the silicon base negative electrode material composition, 1-2% of binder;

[0035] 1. The high-nickel positive electrode material is prepared by the following method:

[0036] 1) Mix nickel oxide, manganese oxide, lithium oxide and lutetium oxide by ball milling to obtain a uniform powder. The molar ratio of ni...

Embodiment 2

[0059] Example 2: The difference from Example 1 is that in the positive electrode material composition, the binder is 2.1%, the conductive agent is 2.9%, and the balance is the positive electrode active material. The negative electrode material composition includes the following components by weight percentage: 1.6% of binder; 3.6% of conductive agent, 1.6% of thickener, and the balance is negative electrode active material.

Embodiment 3

[0060] Example 3: The difference from Example 1 is that in the positive electrode material composition, the binder is 2.2%, the conductive agent is 2.5%, and the balance is the positive electrode active material. The negative electrode material composition includes the following components in terms of weight percentage: 2% binder; 2.8% conductive agent, 2 thickeners, and the balance is negative active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com