Carboxyl group-containing beaten acrylonitrile-based fibers, production method for said fibers, and structure containing said fibers

An acrylonitrile-based, manufacturing method technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber treatment, fiber type, etc., can solve the problems of poor shape stability, easy shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

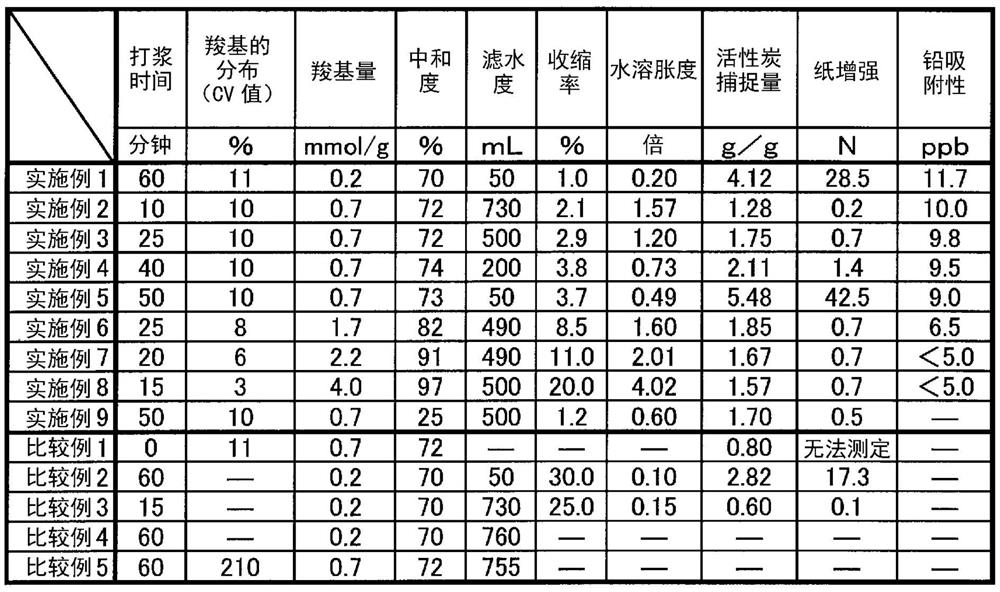

Embodiment 1

[0086] 90 parts of 44% sodium thiocyanate aqueous solution dissolved with 10 parts of acrylonitrile-based polymers containing 90% of acrylonitrile and 10% of methyl acrylate were spun out in a coagulation bath at -2.5°C for coagulation , washing with water, and stretching 12 times to obtain a gel-like acrylic fiber with a moisture content of 35%. The fibers were immersed in 1.5% aqueous sodium hydroxide solution, extruded, hydrolyzed at 123°C for 25 minutes in a hot and humid atmosphere, washed with water, and dried at 105°C for 1 hour to obtain unbeaten fibers. This unbeaten fiber is cut into 4mm, after forming the water slurry of concentration 1%, with Niagara beater (BE-23 manufactured by Kumagai Riki Industry Co., Ltd.), carry out beating process with the beating time recorded in Table 1 with a weight of 2 kg, The beaten acrylic fiber of Example 1 was obtained. In addition, the freeness of the unbeaten fiber cut into 4 mm was 760 ml.

Embodiment 2~5

[0088] In the formulation of Example 1, the concentration of the aqueous sodium hydroxide solution was changed to 4.0%, and the beating treatment was carried out with the beating time recorded in Table 1, except that the beating-like acrylonitrile of Examples 2 to 5 was obtained in the same manner. Department of fiber.

Embodiment 6~8

[0090] In the formula of embodiment 1, for the concentration of aqueous sodium hydroxide solution, change to 7.5% in embodiment 6, change to 10.0% in embodiment 7, change to 20.0% in embodiment 8, and with the beating described in table 1 Except that the beating treatment was performed over a period of time, the beaten acrylic fibers of Examples 6 to 8 were obtained in the same manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com