Preparation method of hydrophilic lubricating coating on surface of PVC catheter

A technology for lubricating coatings and catheters, applied in catheters, coatings, etc., to achieve the effects of convenient use, simple equipment and good coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

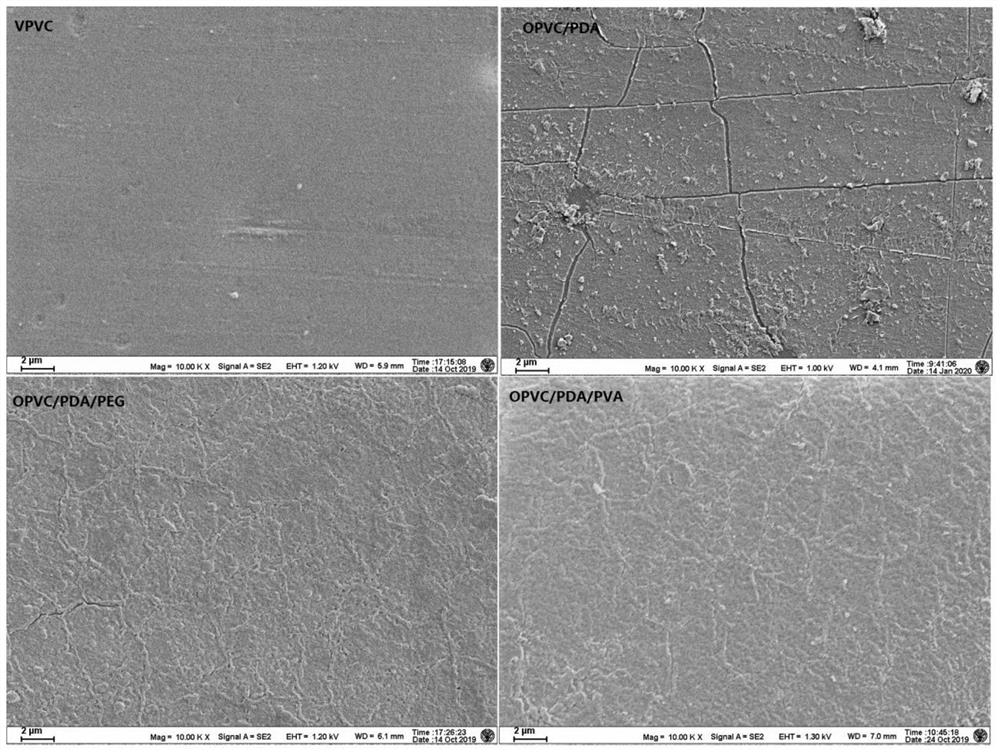

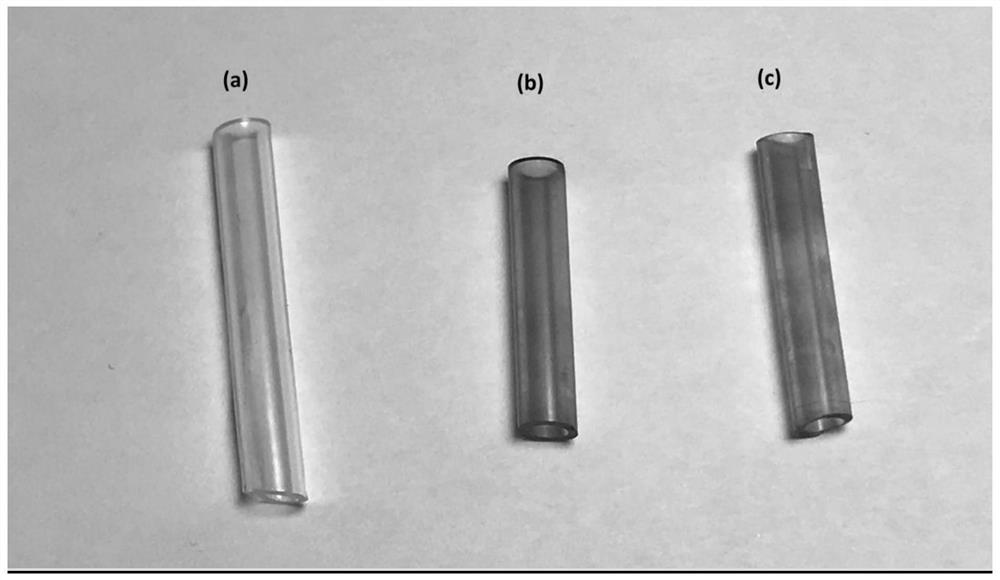

Embodiment 1

[0030] Treat PVC catheter with oxygen plasma for 50s; immerse in Tris-Hcl buffer solution (Tris concentration = 0.01mol / L) with PH=8-9 and dopamine concentration of 2mg / ml to modify at room temperature for 24h; The dopamine-modified urinary catheter was soaked for 30 minutes, and washed three times with deionized water; the cleaned urinary catheter was placed in the above-mentioned Tris-Hcl buffer with an amino PEG concentration of 2 mg / ml, and modified at a constant temperature of 50°C for 24 hours.

Embodiment 2

[0032] Treat PVC catheter with oxygen plasma for 50s; immerse in Tris-Hcl buffer solution (Tris concentration = 0.01mol / L) with PH=8-9 and dopamine concentration of 2mg / ml to modify at room temperature for 28h; The dopamine-modified urinary catheter was soaked for 30 minutes, and washed three times with deionized water; the cleaned urinary catheter was placed in the above-mentioned Tris-Hcl buffer with an amino-PVA concentration of 1 mg / ml, and modified at a constant temperature of 50°C for 12 hours.

Embodiment 3

[0034] Treat PVC catheter with oxygen plasma for 30s; immerse in Tris-Hcl buffer solution (Tris concentration = 0.01mol / L) with PH=8-9 and dopamine concentration of 2mg / ml for modification at room temperature for 6h; Soak the dopamine-modified urinary catheter for 30 minutes, and wash it three times with deionized water; put the cleaned urinary catheter into the above-mentioned Tris-Hcl buffer solution with an amino PEG concentration of 1.5 mg / ml, and modify it at a constant temperature of 50°C for 6 hours .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com