Multilayer vacuum cooling crystallization device for magnesium vapor

A technology of vacuum cooling and crystallization device, which is applied to the improvement of process efficiency, sublimation, chemical instruments and methods, etc., can solve the problems of inability to obtain high-purity magnesium, inability to unload by itself, and limited area of the crystallizer, so as to improve the operability and Safety and reliability, avoiding the hidden danger of left and right swinging, and improving the effect of cooling and crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

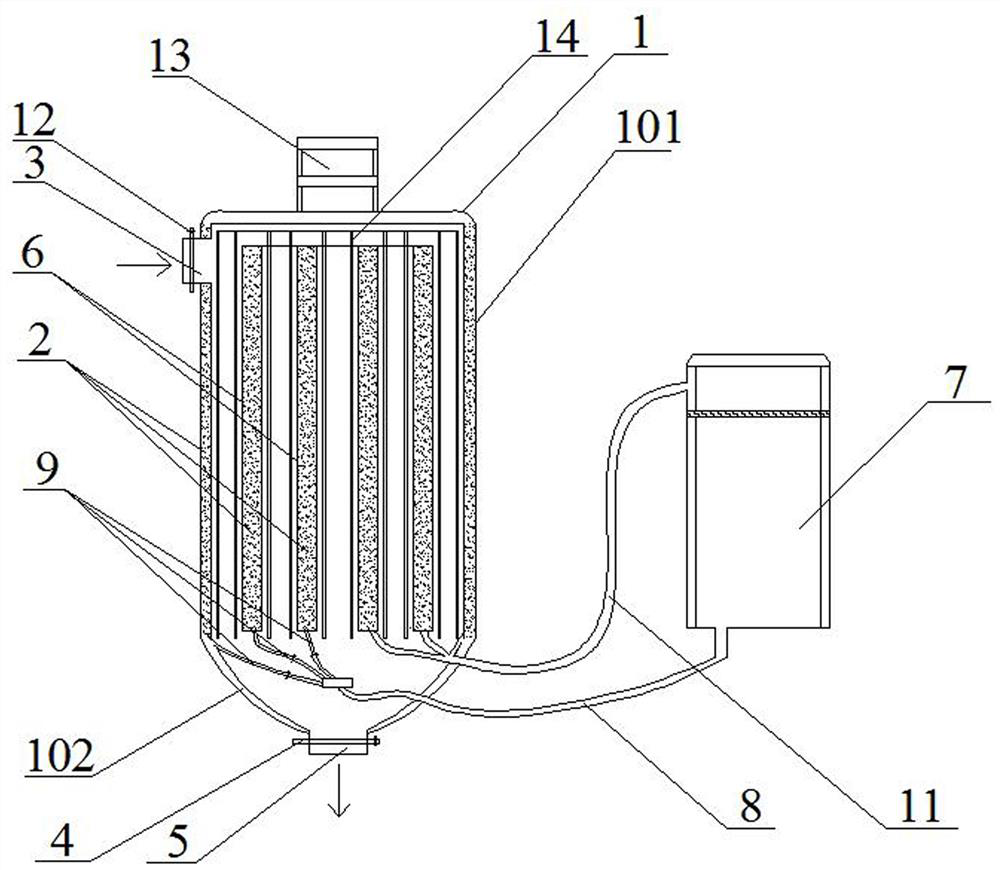

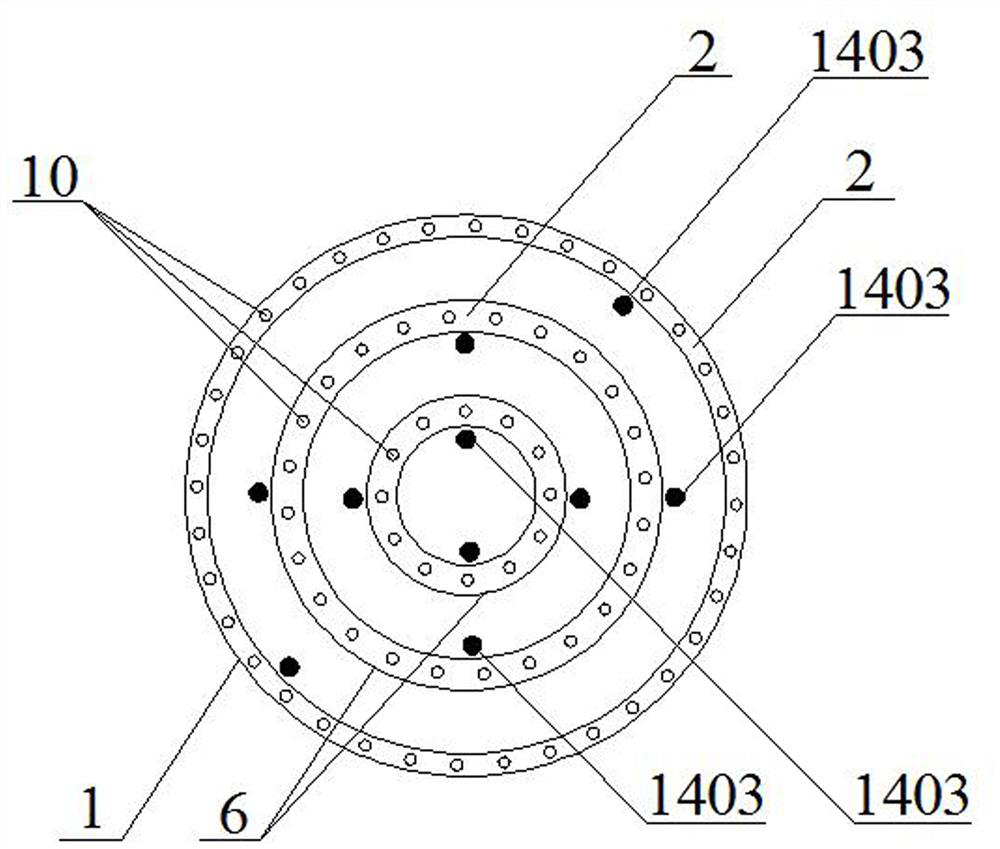

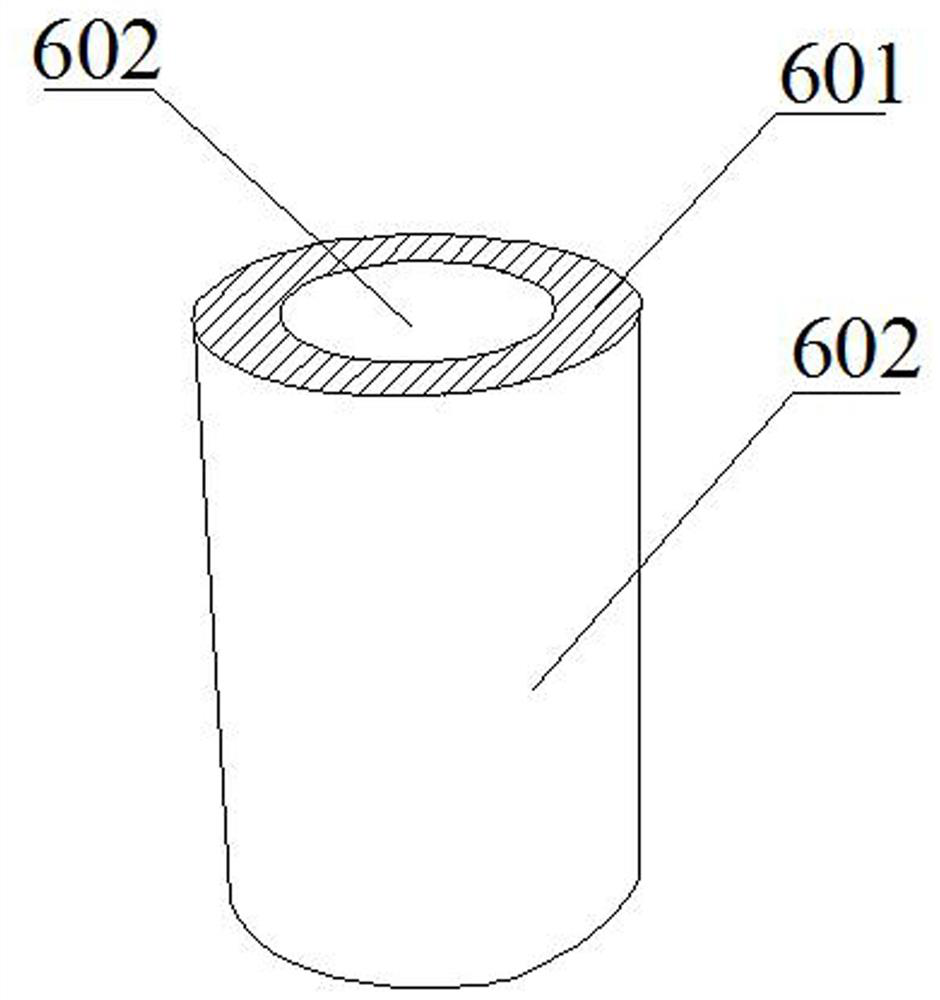

[0025] As shown in the figure, a multi-layer vacuum cooling crystallization device for magnesium vapor includes a vertical double-layer shell 1, an internal multi-layer crystallization assembly, a circulating water cooling assembly and a control mechanism, and the vertical double-layer shell The body 1 is composed of an upper crystallization section 101 and a lower collection section 102 which are butted up and down, wherein the upper crystallization section 101 is a vertical double-layer cylindrical structure with an open lower end, and is provided between the double-layer cylindrical structures. The interlayer cavity 2 through which the cooling water passes is also provided with a magnesium vapor inlet 3 on the side wall of the upper crystallization section 101. The magnesium vapor inlet 3 is provided with a feed valve 12, and the feed valve 12 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com