Production line equipment and process for preparing high-purity magnesium alloy through continuous vacuum smelting

A production line equipment and vacuum melting technology, applied in the field of industrial magnesium alloy preparation devices, can solve the problems of container contamination of magnesium and magnesium alloys, affecting the purity and quality of finished products, and high energy consumption of equipment, so as to increase the crystallization area that can be used for cooling and improve cooling. Excellent crystallization efficiency and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing, the present invention is described in further detail:

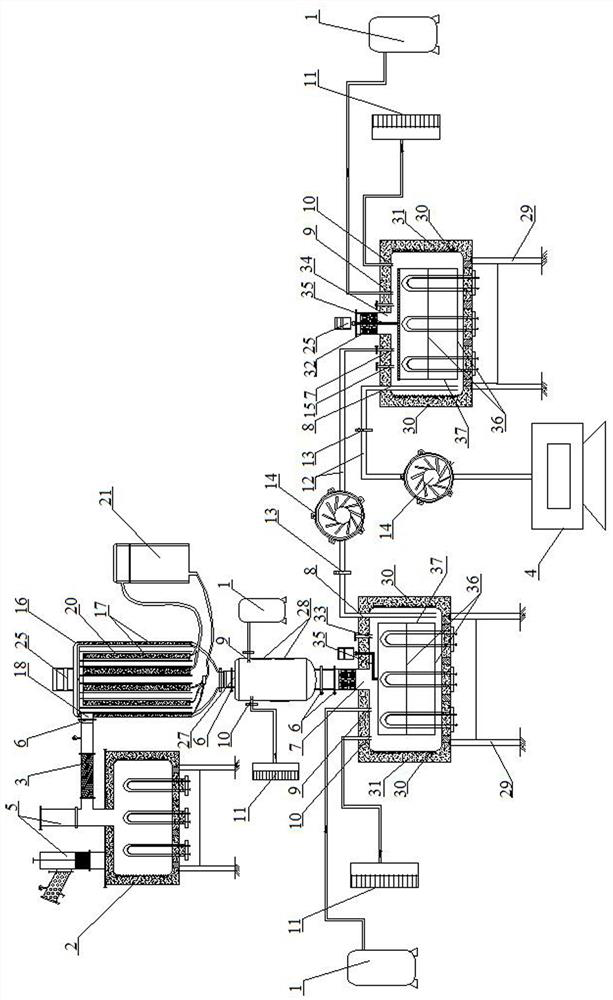

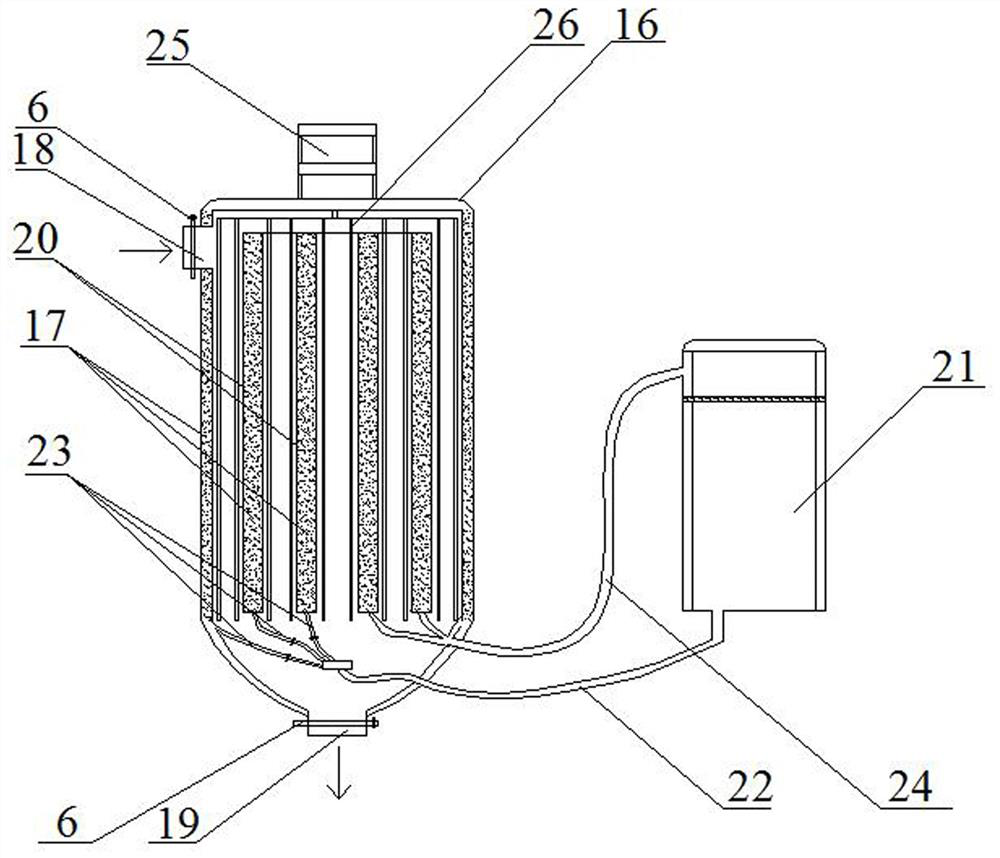

[0050] As shown in the figure, a production line equipment for continuous vacuum smelting to prepare high-purity magnesium alloys, including a vacuum assembly 1 and a control mechanism connected to the vacuum assembly 1, a heating volatilization furnace 2, a magnesium vapor filter device 3, a cooling crystallizer, a vacuum Receiver, crystal melting furnace, alloy melting furnace and alloy forming device 4, the vacuum pumping assembly 1 in this application can be one, also can be multiple, according to actual equipment needs layout setting, described vacuum pumping assembly 1 can be in Under the control of the control mechanism, vacuumize the inside of the heating volatilization furnace 2, magnesium vapor filtering device 3, cooling crystallizer, vacuum receiver, crystal melting furnace, alloy melting furnace and alloy forming device 4; the production line equipment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com