Method for preparing hydrogenated rosin through rosin hydrogenation and catalyst thereof

A technology for rosin hydrogenation and hydrogenation of rosin, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high catalyst cost, poor recycling effect, low catalytic activity, etc. The effect of improved efficiency, low cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Catalyst Ni / CxNy@mSiO 2 preparation of

[0023] S 1 , Amphiphilic nano-mesoporous material CxNy@mSiO 2 The preparation of 0.16g CTAB (cetyltrimethylammonium bromide) and 5mLEDA (ethylenediamine) were weighed respectively and dispersed in the mixed solution of ethanol and water of 50mL (ethanol: water=3:7) , then add 0.12g resorcinol, ultrasonically disperse for 30min, add 0.24mL formaldehyde dropwise, stir for 2h, then add 50mg CTAB, add 0.8mLTEOS (tetraethyl orthosilicate) dropwise, continue stirring for 12h, and then stand for aging 48h, centrifugal separation, and finally high-temperature carbonization under argon atmosphere to obtain the amphiphilic nano-mesoporous material CxNy@mSiO 2 ;

[0024]S 2 , Amphiphilic nanocatalyst Ni / CxNy@mSiO 2 Preparation, weigh 200mg CxNy@mSiO 2 Add it into a three-necked flask, ultrasonically disperse in ethanol solution at room temperature, and then add 50mg NiCl 2 , continue to disperse for 10min, then weigh 30mgN...

Embodiment 2

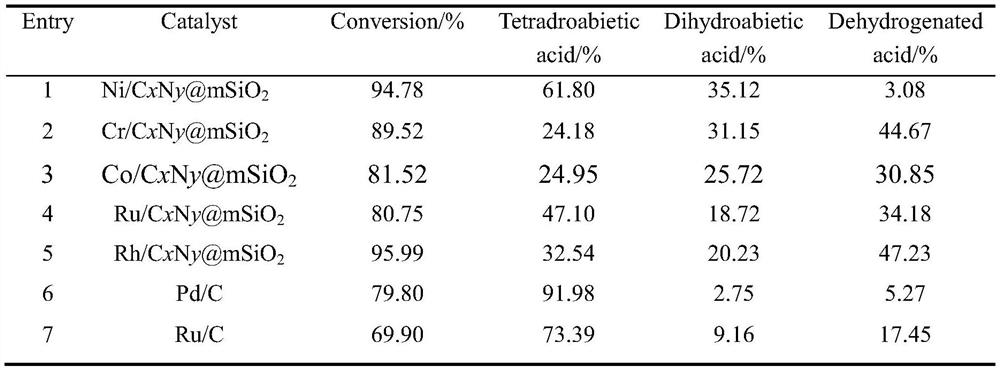

[0025] Embodiment 2 rosin hydrogenation prepares hydrogenated rosin

[0026] Weigh 1g of rosin and add it to a stainless steel mechanically stirred tank, then add 4mL of water and 6mL of 200# solvent oil, and weigh 40mg of the amphiphilic catalyst Ni / CxNy@mSiO 2 Mix evenly, replace the gas in the kettle with 1MPa hydrogen for 4 times, then flush into 4MPa hydrogen, and react with mechanical stirring at 140°C for 4 hours. After the reaction, let stand for a period of time to separate the catalyst from the product, collect the upper product phase and use chromatography Quantitative analysis shows that the conversion rate of rosin reaches 94.78%, the selectivity of tetrahydroabietic acid in the product is 61.80%, and the selectivity of dihydroarginic acid is 35.12%, which meet the requirements of super-grade rosin.

Embodiment 3

[0027] Embodiment 3 rosin hydrogenation prepares hydrogenated rosin

[0028] Weigh 1g of rosin and add it to a stainless steel mechanically stirred tank, then add 4mL of water and 6mL of 200# solvent oil, and weigh 40mg of the amphiphilic catalyst Ni / CxNy@mSiO 2 Mix evenly, replace the gas in the kettle with 1MPa hydrogen for 4 times, then pour in 2MPa hydrogen, and react with mechanical stirring at 120°C for 2 hours. Quantitative analysis by chromatography shows that the conversion rate of rosin reaches 92.09%, the selectivity of tetrahydroabietic acid in the product is 61.17%, and the selectivity of dihydroarginic acid is 29.09%, which meets the requirements of super-grade rosin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com