Soybean uniform crushing and guiding device

A material guiding device and uniform technology, applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of crushing accuracy, insufficient fineness adjustment, and narrow working range of the crushed working surface, so as to achieve sufficient rotational torque, The effect of expanding the operating range and improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

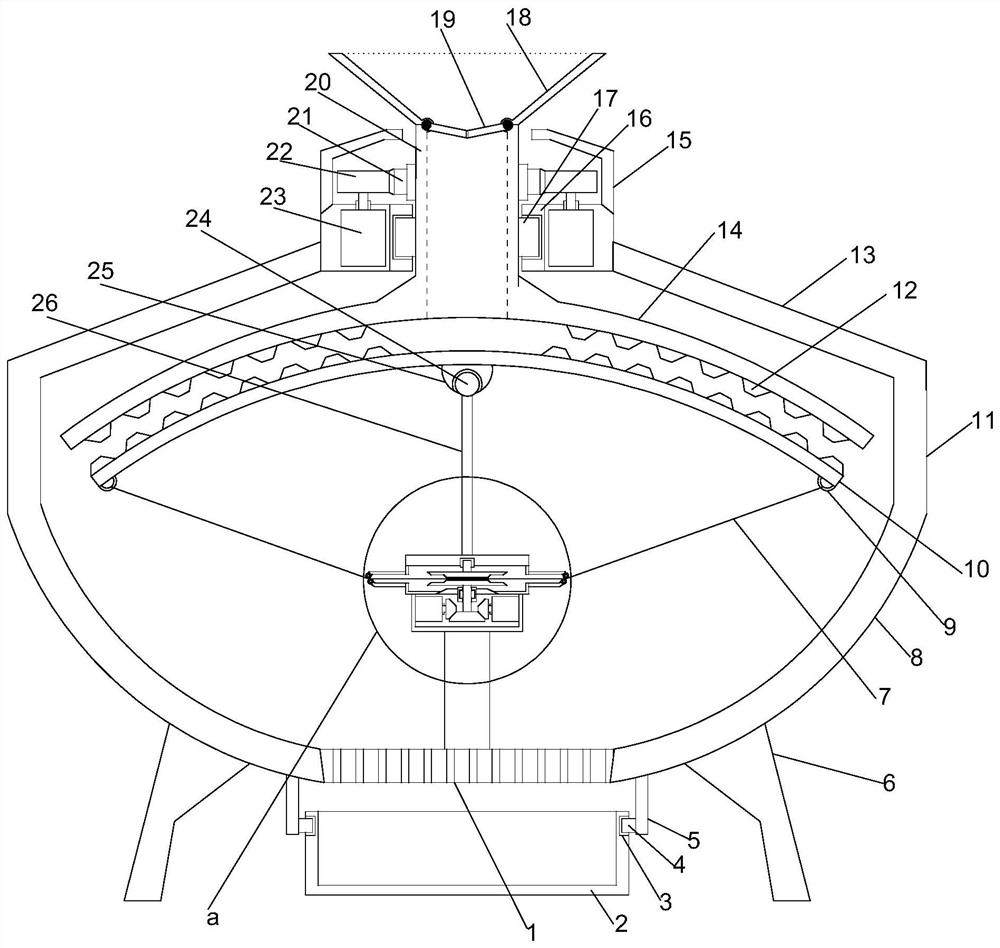

[0021] see Figure 1~3 , in an embodiment of the present invention, a soybean uniform crushing guide device includes a vertically arranged support installation cylinder 11, the lower end of the support installation cylinder 11 is provided with an arc-shaped material guide cylinder 8, and the upper end of the support installation cylinder 11 is vertically arranged There is a cone surface installation cylinder 13, the upper end of the cone surface installation cylinder 13 is vertically provided with a transmission installation cover 15, the lower end of the arc surface material guide cylinder 8 is horizontally provided with a porous material guide plate 1, and the arc surface guide plate 1 outside the porous material guide plate 1 The lower end of the barrel 8 is provided with several support installation columns 6 at equal angles, and the middle position of the transmission installation cover 15 is vertically provided with a rotating material guide cylinder 20, which runs throug...

Embodiment 2

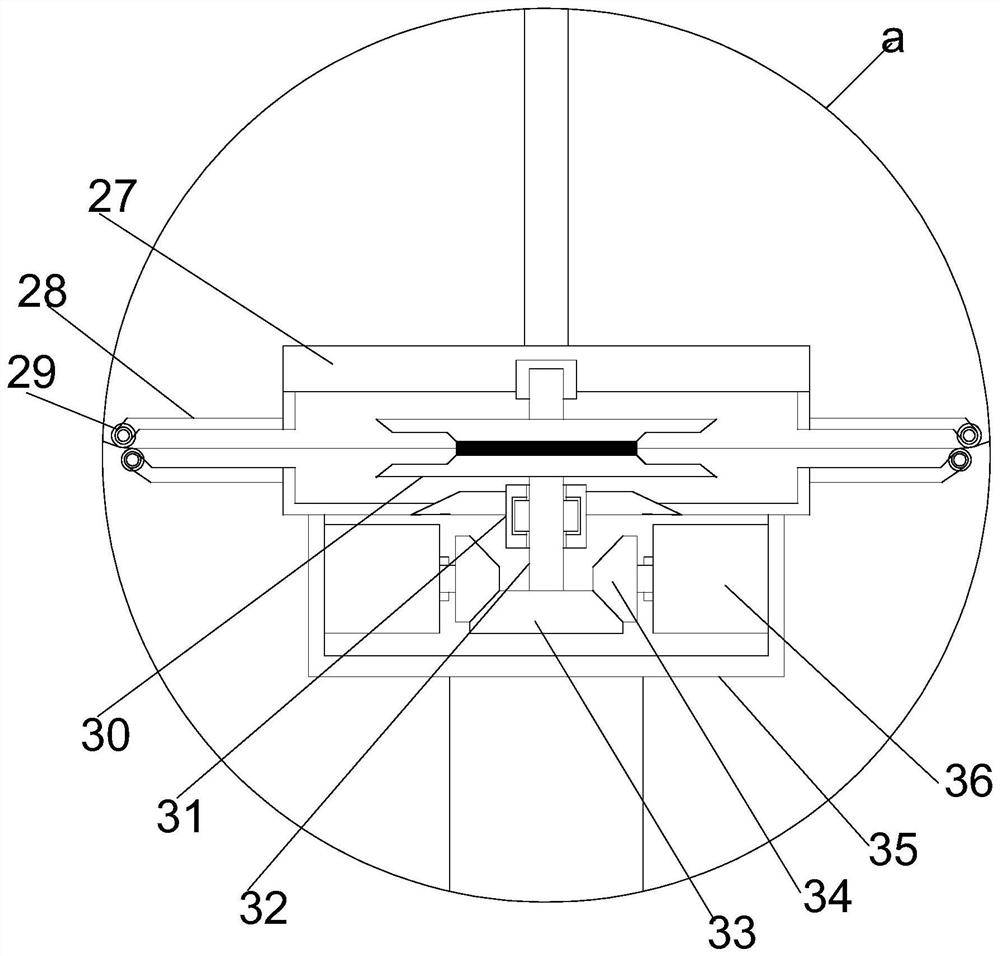

[0024] On the basis of Embodiment 1, when the soybeans are crushed, the working motor 36 is started, so that the working bevel gear 34 and the transmission bevel gear 33 are connected together, so that the limit rotating shaft 32 rotates together with the rotating reel 30, and the traction rope 7 is controlled. The protruding length, so as to control the curvature of the deformation rotating disk 10, realize the gap between it and the spherical rotating disk 14, so that the crushing accuracy of soybeans can be adjusted efficiently and comprehensively, and it can also adapt to the crushing treatment of other beans with different diameters. The operating range of the device is expanded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com