Composite board of artificial base material and adhesive impregnated veneer and production process

A composite board and production process technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of poor flame retardancy and waterproof performance, poor texture and visual aesthetics, stability and aesthetics Discount and other issues, achieve strong wear resistance, strong texture and visual aesthetics, and ensure the effect of pressing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

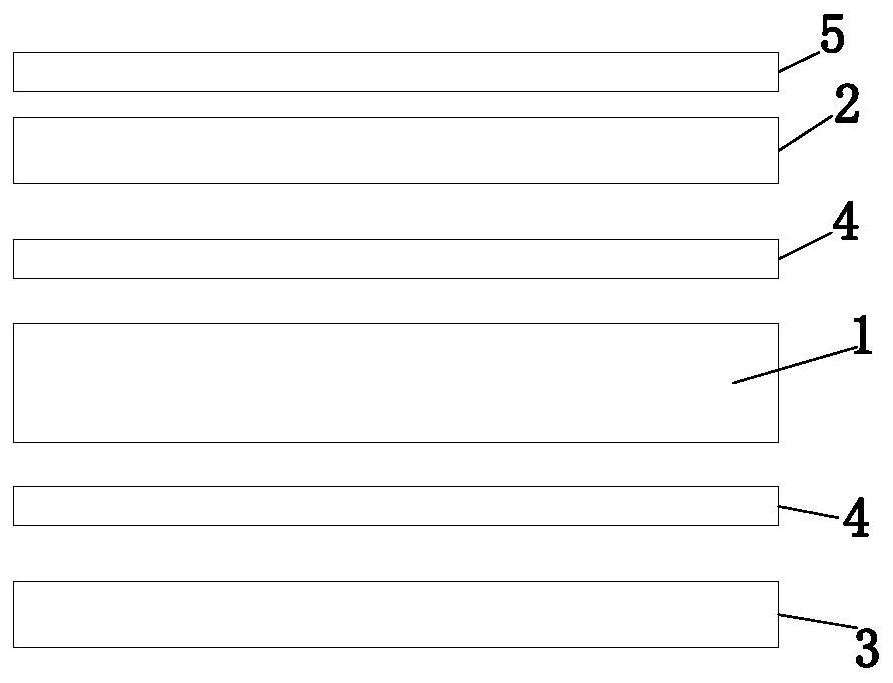

[0026] Example 1. Composite panels of man-made base material and glue-impregnated veneer, constituted as figure 1 As shown, it includes a man-made base material 1, and the front side of the man-made base material 1 is provided with a veneer 2 impregnated with melamine glue.

[0027] The reverse side of the artificial substrate 1 is provided with melamine impregnated paper 3 .

[0028] Waterproof and high-temperature-resistant adhesive glue layers 4 are provided between the melamine glue-impregnated veneer 2 and the artificial substrate 1 and between the artificial substrate 1 and the melamine-impregnated paper 3 .

[0029] Water-based acrylic emulsion, U961, can be used as waterproof and high-temperature-resistant bonding glue.

[0030] A melamine wear-resistant layer 5 is arranged above the veneer 2 impregnated with melamine glue.

[0031] The artificial substrate 1 is vinyl material.

[0032] The production process of the composite board of artificial substrate and glue-...

Embodiment 2

[0050] Example 2. Composite panels of man-made base material and glue-impregnated veneer, constituted as figure 1 As shown, it includes a man-made base material 1, and the front side of the man-made base material 1 is provided with a veneer 2 impregnated with melamine glue.

[0051] The reverse side of the artificial substrate 1 is provided with melamine impregnated paper 3 .

[0052] Waterproof and high-temperature-resistant adhesive glue layers 4 are provided between the melamine glue-impregnated veneer 2 and the artificial substrate 1 and between the artificial substrate 1 and the melamine-impregnated paper 3 .

[0053] A melamine wear-resistant layer 5 is arranged above the veneer 2 impregnated with melamine glue.

[0054] The artificial substrate 1 is vinyl material.

[0055] The production process of the composite board of artificial substrate and glue-impregnated veneer comprises the following steps:

[0056] A, the surface of the artificial substrate is frosted to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com