Tin-carbon co-doped titanium niobate material as well as preparation method and application thereof

A technology of co-doping and titanium niobate, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of high energy consumption and complicated preparation process, and achieve simple preparation method, excellent specific capacity and long cycle The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

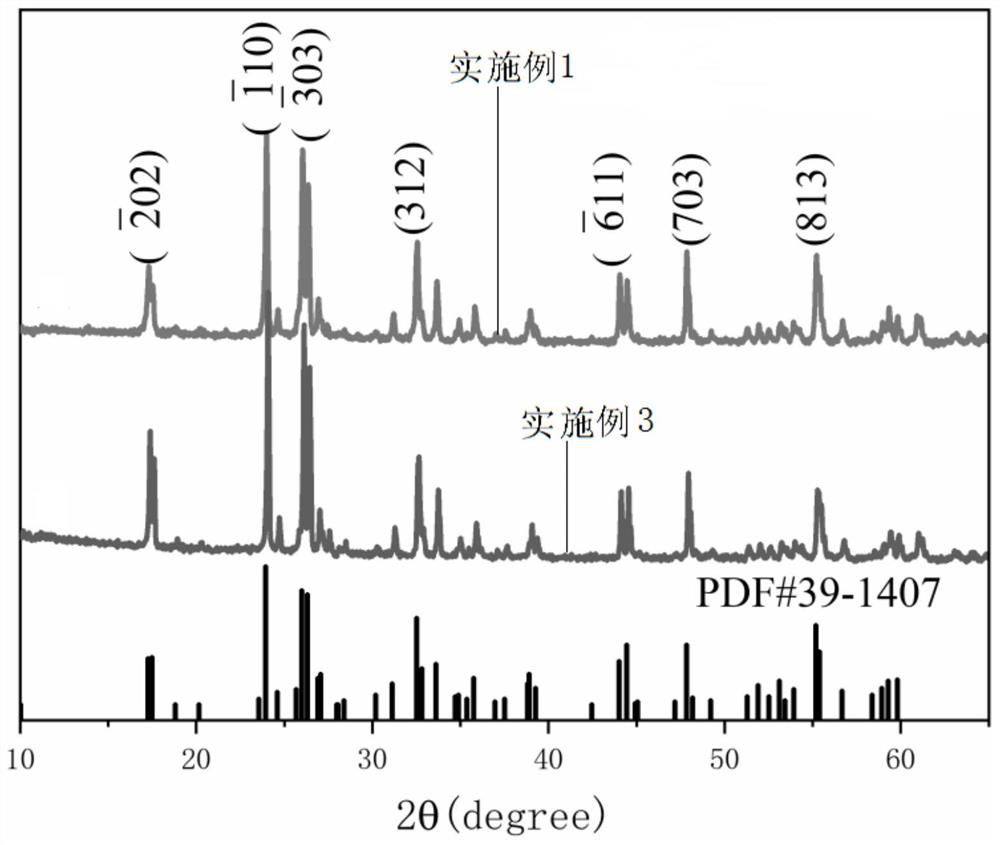

[0027] A tin-carbon co-doped titanium niobate material, the molar fraction of tin in the tin-carbon co-doped titanium niobate material is 8%, and the mass of carbon in the tin-carbon co-doped titanium niobate material is The score is 1.53%.

[0028] The preparation method of the above-mentioned tin-carbon co-doped titanium niobate material comprises the following steps:

[0029] (1) Weigh 2.65g of niobium pentoxide (Nb 2 o 5 ), 587mg of titanium dioxide (TiO 2 ), 256 mg of dodecyl stannoic acid (C 12 h 25 SnOOH) was added into 10.0mL of absolute ethanol to obtain a mixed solution, then the mixed solution was placed in a zirconia ball mill jar, and ball milled on a star ball mill, the rotating speed of the ball mill was set to 300rpm, and the ball milling time was 8 hours, and the ball milling was completed Finally, the mixed solution was transferred to a blast drying oven, dried at 80°C for 3 hours, and the solid collected after drying was the precursor;

[0030] (2) Put...

Embodiment 2

[0032] A tin-carbon co-doped titanium niobate material, the molar fraction of tin in the tin-carbon co-doped titanium niobate material is 6%, and the mass of carbon in the tin-carbon co-doped titanium niobate material is The score is 1.02%.

[0033] The preparation method of the above-mentioned tin-carbon co-doped titanium niobate material comprises the following steps:

[0034] (1) Weigh 2.65g of niobium pentoxide (Nb 2 o 5 ), 600mg of titanium dioxide (TiO 2 ), 192mg of dodecyl stannoic acid (C 12 h 25 SnOOH) was added into 10.0mL of absolute ethanol to obtain a mixed solution, then the mixed solution was placed in a zirconia ball mill jar, and ball milled on a star ball mill, the rotating speed of the ball mill was set to 300rpm, and the ball milling time was 8 hours, and the ball milling was completed Finally, the mixed solution was transferred to a blast drying oven, dried at 80°C for 3 hours, and the solid collected after drying was the precursor;

[0035] (2) Put ...

Embodiment 3

[0041] A tin-carbon co-doped titanium niobate material, the molar fraction of tin in the tin-carbon co-doped titanium niobate material is 8%, and the mass of carbon in the tin-carbon co-doped titanium niobate material is The score is 2.55%.

[0042] The preparation method of the above-mentioned tin-carbon co-doped titanium niobate material comprises the following steps:

[0043] (1) Weigh 2.65g of niobium pentoxide (Nb 2 o 5 ), 587mg of titanium dioxide (TiO 2 ), 504mg of dibutyltin dilaurate (Bu 2 Sn(OOCC 11 h 23 ) 2 ) was added to 10.0mL of absolute ethanol to obtain a mixed solution, then the mixed solution was placed in a zirconia ball mill jar, and ball milled on a star ball mill, the rotating speed of the ball mill was set to 300rpm, and the ball milling time was 8 hours. Transfer the mixed solution to a blast drying oven, dry at 80°C for 3 hours, and collect the solid as the precursor after drying;

[0044] (2) Put the precursor obtained in the above steps into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com