Energy-saving treatment process for textile printing and dyeing wastewater

A technology of textile printing and dyeing and treatment process, which is applied in the field of energy-saving treatment process of textile printing and dyeing wastewater, which can solve the problems of affecting the efficiency of continuous sedimentation of wastewater, low mixing efficiency of flocculant and wastewater, and low cleaning efficiency, so as to increase the efficiency of classification treatment, Guarantee the efficiency of static settlement and increase the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

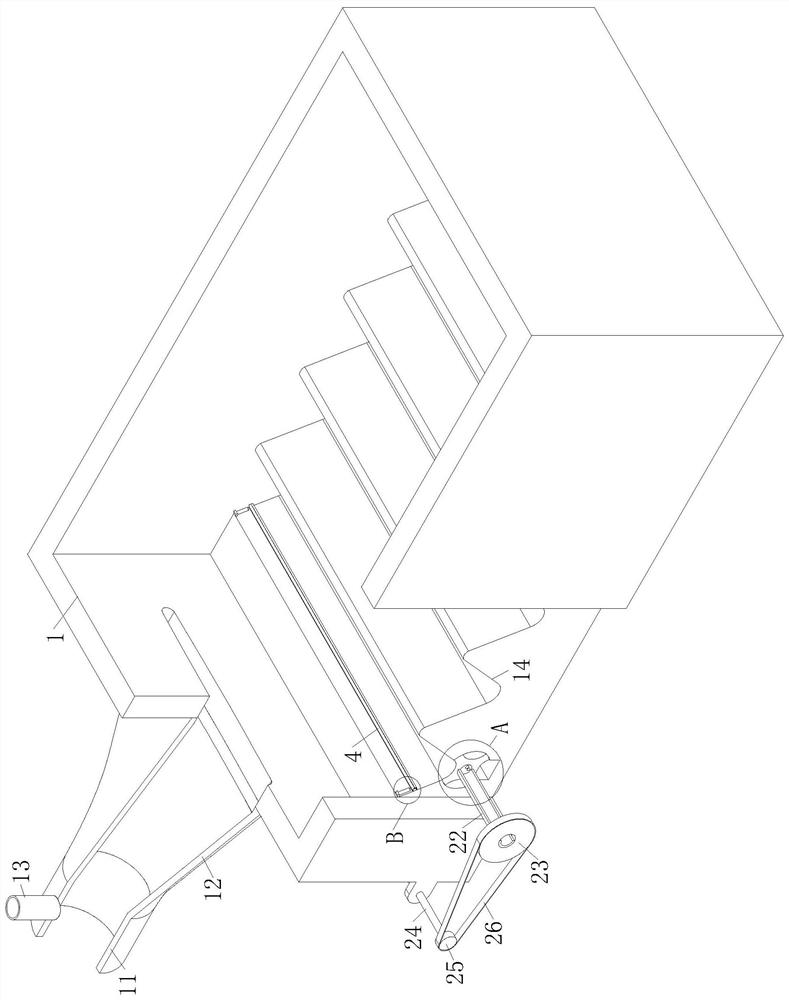

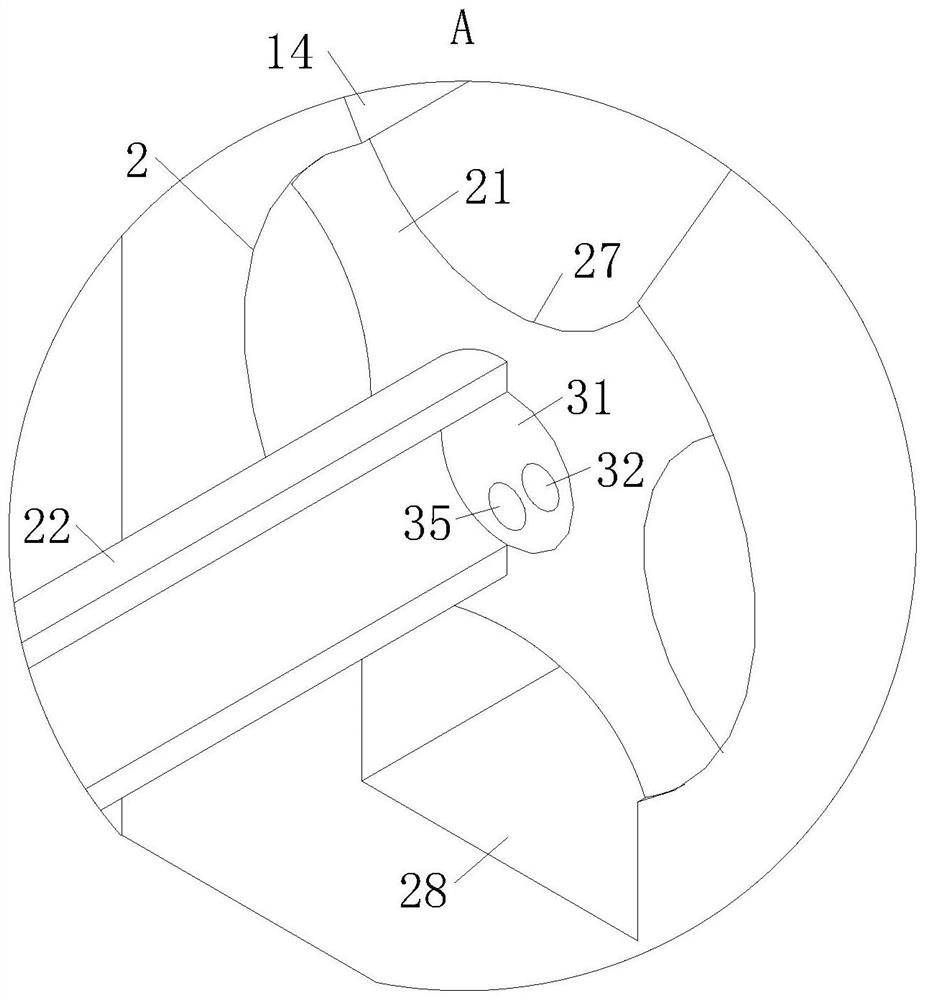

[0034] As an embodiment of the present invention, an arc-shaped chute 2 is provided at the bottom of the groove 14, and a dredging column 21 is rotatably connected in the chute 2; The pool body 1 extends to the outside of the pool body 1; the shaft sleeve 22 is fixedly connected with a No. 1 pulley 23, and the pool body 1 is connected with a drive shaft 24 through a support for rotation. The drive shaft 24 corresponds to the No. 1 pulley 23 The position is fixedly connected with the second pulley 25, and the transmission between the first pulley 23 and the second pulley 25 is driven by a belt 26; the drive shaft 24 is driven by a reduction motor fixedly connected to one side of the pool body 1; the shaft sleeve The rotating speed of 22 is lower than 10r / h; The outer circumference of the dredging column 21 is evenly distributed with a group of arc-shaped grooves 27 along the axial direction; the bottom of the chute 2 is provided with a discharge groove 28, and the discharge groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com