Pig manure biological treatment process and utilization method

A technology of biological treatment and feces treatment, applied in the field of pig manure biological treatment process and utilization, can solve the problem that pig manure cannot be fully treated, and achieve the effect of reasonable structure design and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

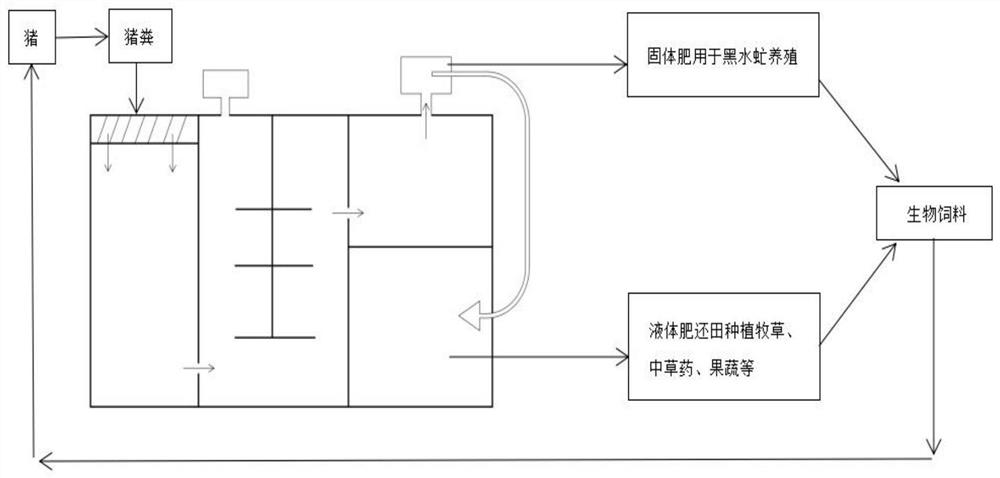

[0027] A kind of pig manure biological treatment process, comprises the following steps:

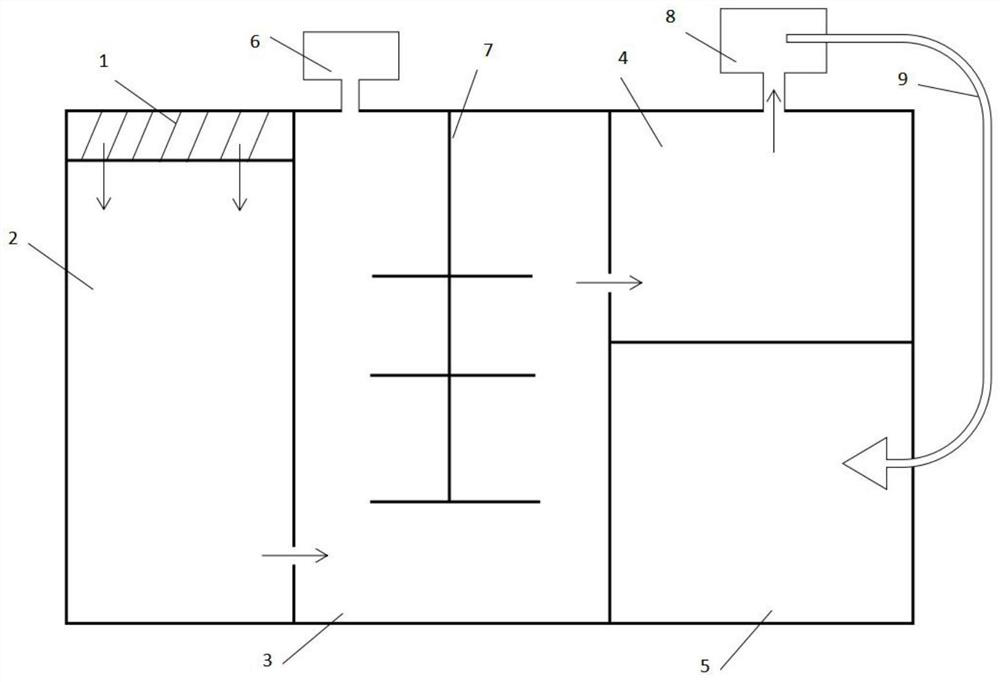

[0028] S1: Put the pig manure into the manure treatment tank. The pig manure first passes through the debris grid 1 to filter out large debris, and then enters the manure concentration tank 2 to further precipitate impurities. When the fermentation tank 3 is full, add weight from the storage tank 6 0.1% by weight of pig manure compound bacterial agent, 2% by weight of pig manure modifier and 6% by weight of pig manure additives, open the agitator 7 and stir for 2 hours to mix evenly, then ferment at 25 ° C for 48 hours to keep the fermented product The water content of the pig manure is 50%, and the fermented product is stirred for 30 minutes every 12 hours; the temperature is raised, and the fermented pig manure is fermented at 28°C for 60 hours. The fertilizer delivery pipe 9 enters the liquid fertilizer collection tank 5 to obtain liquid and solid fermented pig manure fertilizer;

[...

Embodiment 2

[0035] A kind of pig manure biological treatment process, comprises the following steps:

[0036] S1: Put the pig manure into the manure treatment tank. The pig manure first passes through the debris grid 1 to filter out large debris, and then enters the manure concentration tank 2 to further precipitate impurities. When the fermentation tank 3 is full, add weight from the storage tank 6 0.4% by weight of pig manure compound bacterial agent, 4% by weight of pig manure modifier and 11% by weight of pig manure additives, open the agitator 7 and stir for 5 hours to mix evenly, and then ferment at 29 ° C for 72 hours to keep the fermented product The water content of the pig manure is 70%, and the fermented product is stirred for 60 minutes every 12 hours; the temperature is raised, and the fermented pig manure is fermented for 96 hours at 35°C. The fermented pig manure enters the purification tank 4, and enters the solid-liquid separator 8 after removing harmful substances. The f...

Embodiment 3

[0043] A kind of pig manure biological treatment process, comprises the following steps:

[0044] S1: Put the pig manure into the manure treatment tank. The pig manure first passes through the debris grid 1 to filter out large debris, and then enters the manure concentration tank 2 to further precipitate impurities. When the fermentation tank 3 is full, add weight from the storage tank 6 0.36% of the weight of pig manure compound bacteria, modifier of 3.2% of the weight of pig manure and 8% of the weight of pig manure additives, open the agitator 7 and stir for 3 hours to mix evenly, then ferment at 27 ° C for 62 hours, keep the fermented product The water content of the pig manure is 63%, and the fermented product is stirred for 45 minutes every 12 hours; the temperature is increased, and the fermented pig manure is fermented for 72 hours at 33°C. The fermented pig manure enters the purification tank 4, and enters the solid-liquid separator 8 after removing harmful substances....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com