Metallographic chemical polishing solution and application thereof to field of austenitic stainless steel metallographic detection

A technology of austenitic stainless steel and chemical polishing, applied in the preparation of test samples, etc., can solve problems such as inability to chemical polishing, and achieve the effect of easy control of polishing speed, good polishing effect, and not easy to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

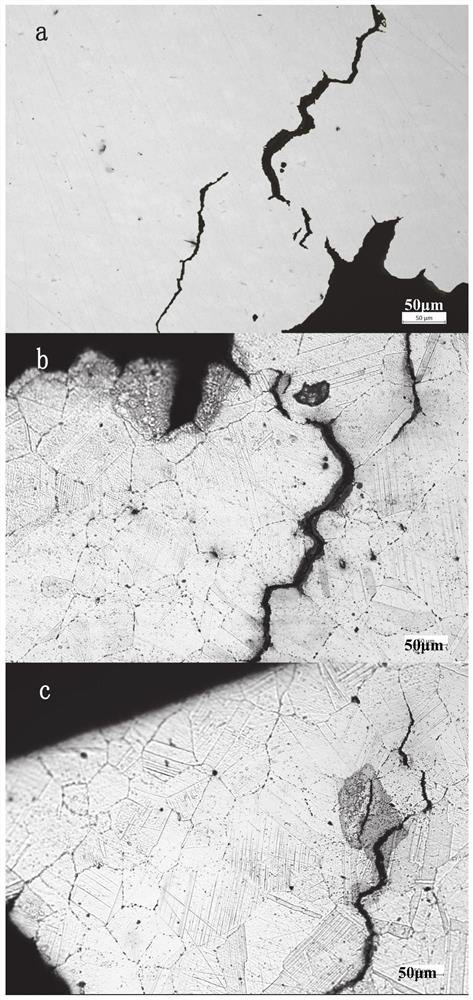

Image

Examples

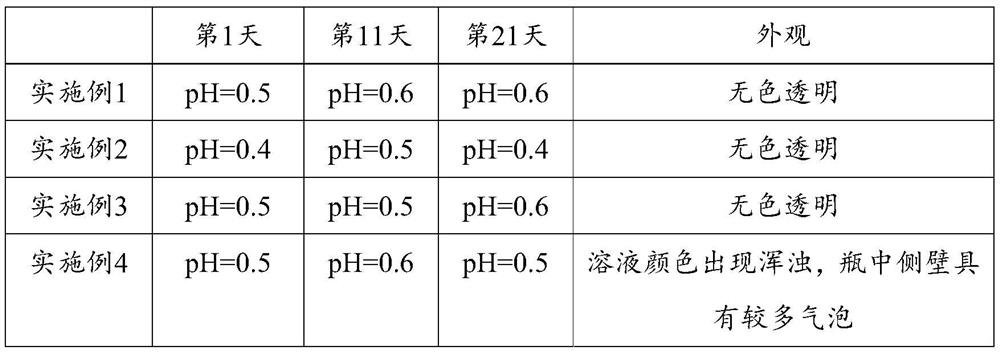

Embodiment 1

[0059] In the present embodiment, a kind of metallographic chemical polishing liquid and preparation method are provided, each component and proportioning ratio are as follows in the described metallographic chemical polishing liquid: hydrochloric acid 130ml / L, phosphoric acid 160ml / L, sodium nitrate 50g / L, 30% Hydrogen peroxide 280ml / L, absolute ethanol 110ml / L, thiourea 6g / L, hydrochloric acid fog suppressant 0.8g / L, and distilled water as the balance.

[0060] Wherein, the hydrochloric acid is 130ml / L and the configuration method is as follows: 130ml of concentrated hydrochloric acid with a mass fraction of 36-38% is added to each L of metallographic chemical polishing solution.

[0061] The 160ml / L of phosphoric acid is configured as follows: 160ml of concentrated phosphoric acid with a mass fraction ≥ 85% is added to each L of metallographic chemical polishing solution.

[0062] The configuration of 280ml / L of 30% hydrogen peroxide is as follows: 280ml of hydrogen peroxid...

Embodiment 2

[0070] In the present embodiment, another kind of metallographic chemical polishing liquid is provided, and each raw material and proportioning ratio in the metallographic chemical polishing liquid are as follows: hydrochloric acid 130ml / L, phosphoric acid 160ml / L, sodium nitrate 50g / L, 30% peroxide Hydrogen 280ml / L, absolute ethanol 110ml / L, thiourea 6g / L, hydrochloric acid fog suppressant 0.8g / L, and distilled water as the balance.

[0071] The hydrochloric acid fog suppressant is Yuantai YT-1101 type.

[0072] The configuration method of the metallographic chemical polishing solution is the same as that described in Example 1.

Embodiment 3

[0074] In the present embodiment, another kind of metallographic chemical polishing liquid is provided, and each raw material and proportioning ratio in the metallographic chemical polishing liquid are as follows: hydrochloric acid 150ml / L, phosphoric acid 120ml / L, sodium nitrate 70g / L, 30% peroxide Hydrogen 310ml / L, absolute ethanol 80ml / L, thiourea 4g / L, hydrochloric acid fog suppressant 1.2g / L, and distilled water as the balance.

[0075] The hydrochloric acid fog suppressant is Yuantai YT-1101 type.

[0076] The configuration method of the metallographic chemical polishing solution is the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com