Slow cutter servo cutter path and design method thereof

A tool path and path technology, which is applied to the field of free-form surface machining with a single-point diamond lathe with slow tool servo, can solve the problems of the machine tool being unable to respond, the machining efficiency is low, and the tracking trajectory error becomes large, and the calculation is simple and convenient. High machining efficiency and the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

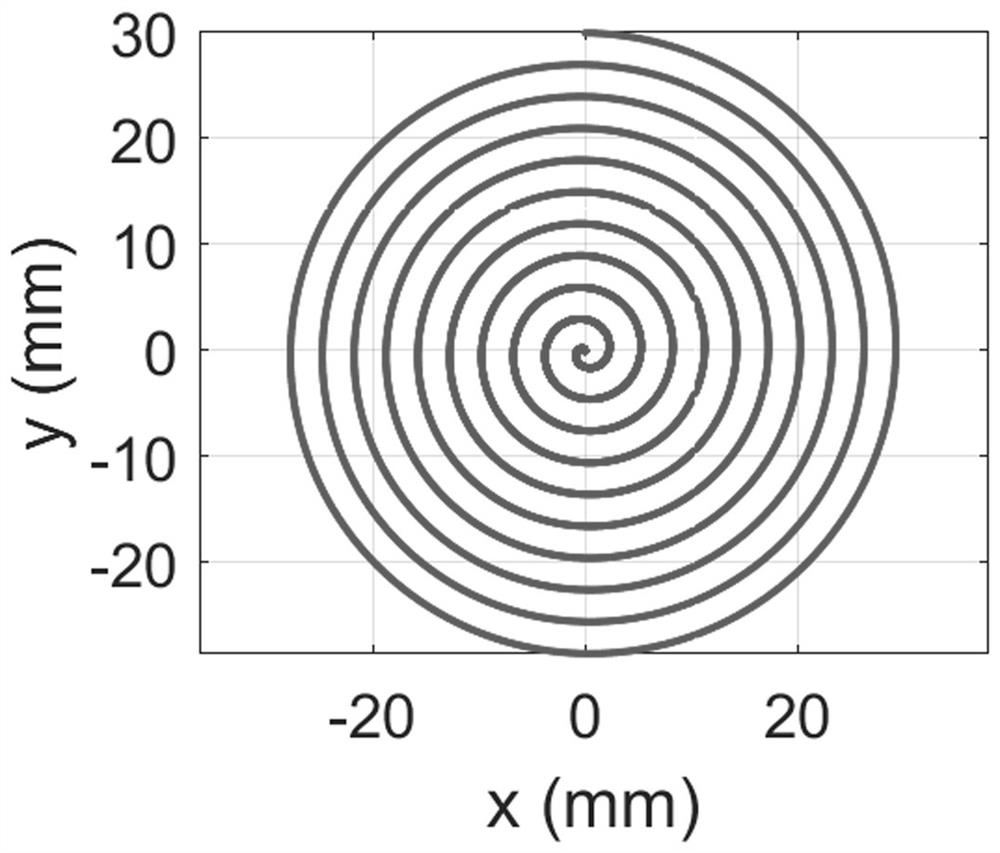

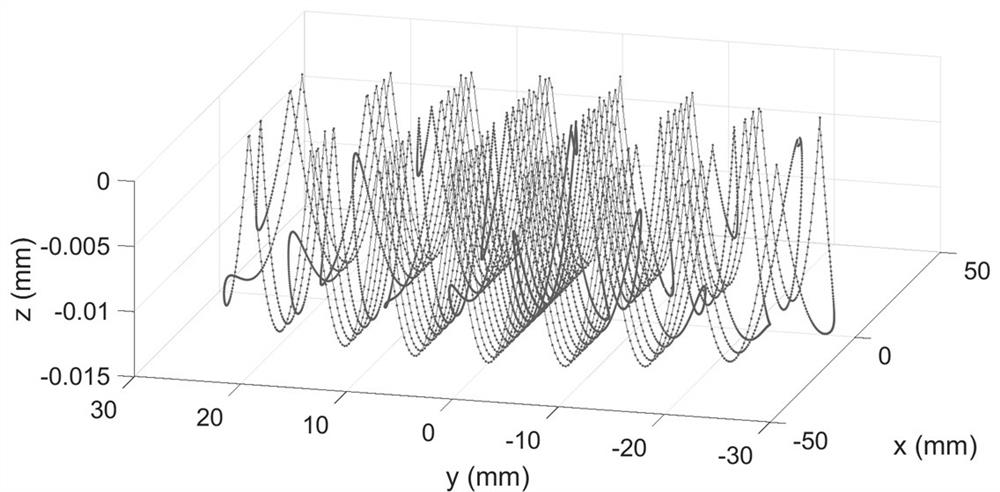

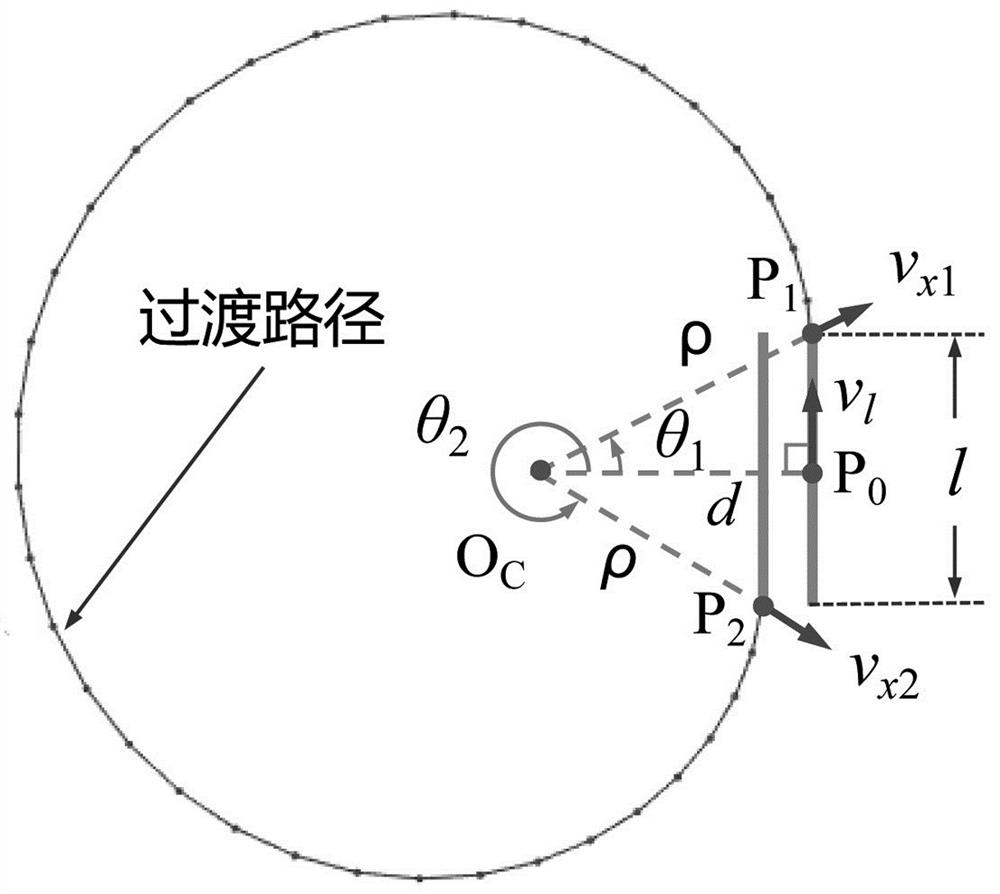

[0068] The workpiece to be processed in this embodiment is a square workpiece, and the side length 1 is 30mm. The surface shape to be processed is a parabolic cylinder array, and the width of each parabolic cylinder is 7mm. Figure 5 shown. The distance d from the outermost edge of the workpiece to the center of C-axis rotation 0 It is 60mm, and the C axis rotates 20 times per minute during processing. Use the formula (2, 3) to calculate the starting polar angle and ending polar angle θ of each effective path 2 and θ 1 , use the formula (1) to calculate the polar diameter ρ of each effective path E (n, θ), solve the equation group (11) to get the polar radius polynomial coefficient c of each transition path m , so that the polar diameter ρ of each transition path can be obtained by formula (4) T (n, θ), use the formula (12, 13) to calculate the z value of each effective path and transition path. In order to display the trajectory of the tool path, the polar angle step is...

Embodiment 2

[0075] The difference between this example and Example 1 is that there are four effective paths in one path cycle, and the centers of the effective paths are located at the four positions where the polar angle θ is 0, π / 2, π and 3π / 2, and the free-form surfaces at the four positions The shape is exactly the same, and the technical scheme proposed by the invention is used to generate four transition paths to smoothly connect four effective paths. Figure 13 is the projection of the tool path on the θ-ρ plane in this embodiment. Figure 14 It is the relationship curve between the X-axis position and the polar angle when the tool path is running on the lathe in this embodiment, and the change curve of the X-axis position in the figure is closer to a sinusoidal curve. Figure 15 is the relationship curve between the X-axis speed and the polar angle when the tool path is running on the lathe in this embodiment, Figure 16 It is the relationship curve between X-axis acceleration an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com