High-strength silicon dioxide aerogel powder and preparation method thereof

A silica and aerogel technology, applied in the field of nanomaterials, can solve the problems of aerogel microstructure and performance damage, complex related processes, etc., to achieve the effect of realizing industrial production, simplifying the entire process, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

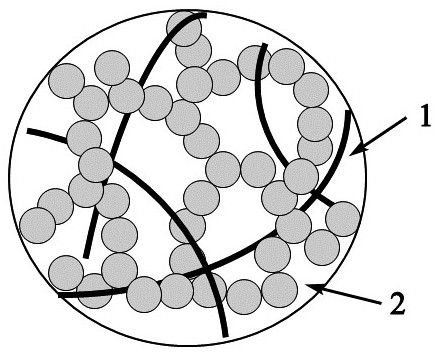

Image

Examples

Embodiment 1

[0038] (1) Preparation of microbial cellulose nanofibers:

[0039] Cut the large-sized coconut flakes into pieces and place them in 25% sulfuric acid to break up the network-like microbial cellulose nanofibers, react at 75°C for 4.5 h, filter with suction, wash 3 times, and then dry to obtain single dispersed microbial cellulose nanofibers;

[0040] Wherein, the mass ratio of coconut fruit and sulfuric acid is 1:6.

[0041] (2) Preparation of silica sol

[0042] Mix and stir 78 mL tetraethyl orthosilicate, 90 mL ethanol and 25 mL deionized water evenly, then add 2 mL 1% hydrochloric acid dropwise, stir for 1 h, then add 9 mL 0.1M ammonia water dropwise Add and stir to obtain a silica sol.

[0043] (3) Preparation of composite wet gel

[0044] Add the monodisperse microbial cellulose nanofibers prepared in step (1) to the silica sol prepared in step (2), stir at 200 rpm for 30 min, then let stand at 50°C for 100 min, then Mechanical pulverization for 7 min to obtain a comp...

Embodiment 2

[0050] (1) Preparation of microbial cellulose nanofibers:

[0051] Cut the large-sized coconut pieces into pieces and place them in 32% sulfuric acid to break up the network-like microbial cellulose nanofibers, react at 65°C for 3.5 h, filter with suction and wash 4 times, then dry to obtain the single dispersed microbial cellulose nanofibers;

[0052] The mass ratio of described coconut fruit and sulfuric acid is 1:5.

[0053] (2) Preparation of silica sol

[0054] Mix and stir 65 mL tetraethyl orthosilicate, 110 mL ethanol and 20 mL deionized water evenly, then add 1.8 mL 1% hydrochloric acid dropwise, stir for 1 h, then add 6.5 mL 0.1M ammonia water dropwise Add and stir to obtain a silica sol.

[0055] (3) Preparation of composite wet gel

[0056] Add the microbial cellulose nanofibers prepared in step (1) to the silica sol prepared in step (2), stir at 200 rpm for 22 min, then stand at 40°C for 140 min, and then mechanically pulverize for 5 min. min, to obtain a compos...

Embodiment 3

[0062] (1) Preparation of microbial cellulose nanofibers:

[0063] Cut the large-sized coconut pieces into pieces and place them in 40% sulfuric acid to break up the network-like microbial cellulose nanofibers, react at 55°C for 2.5 hours, filter with suction, wash 5 times, and then dry to obtain the microorganisms Cellulose nanofibers;

[0064] The mass ratio of described coconut fruit and sulfuric acid is 1:4.

[0065] (2) Preparation of silica sol

[0066] Mix 55 mL of tetraethyl orthosilicate, 120 mL of ethanol and 15 mL of deionized water and stir evenly, then add 1 mL of 1% hydrochloric acid dropwise, and after stirring for 1 h, add 7 mL of 0.1M ammonia water dropwise Add and stir to obtain a silica sol.

[0067] (3) Preparation of composite wet gel

[0068] Add the microbial cellulose nanofibers prepared in step (1) to the silica sol prepared in step (2), stir at 200 rpm for 35 min, then stand at 72°C for 35 min, and then mechanically pulverize for 9 min, to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com