Silicon-based negative electrode material and preparation method and application thereof

A technology of silicon-based negative electrode materials and silicon materials, which is applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low initial charge and discharge efficiency of lithium-ion batteries, poor cycle performance, and volume changes of silicon materials, etc. Effects of initial charge and discharge efficiency, buffering stress, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

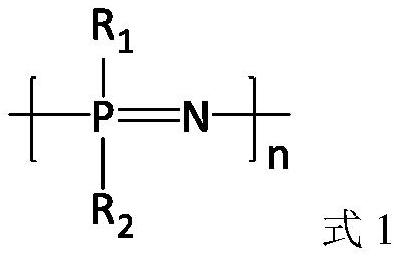

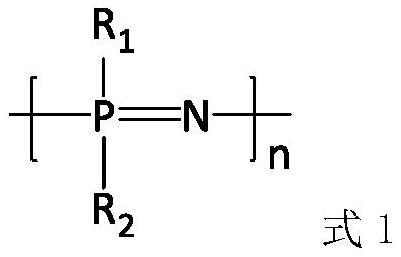

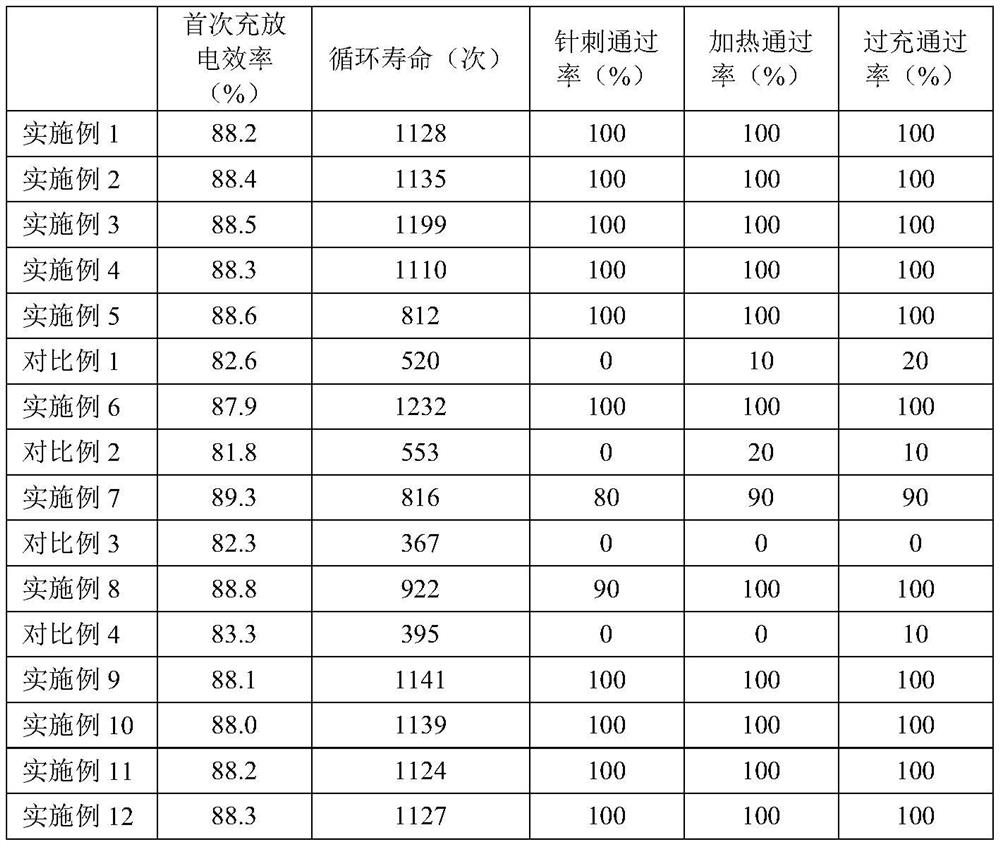

[0036] The silicon-based negative electrode material provided in this example includes silicon oxide and a polymer coated on the surface of silicon oxide, wherein the silicon oxide is in the form of irregular particles, and its Dv50 is 20 μm; the polymer has the structure shown in formula 1 , the average degree of polymerization n is 1000, R 1 and R 2 Both are -Cl, and the mass of the polymer is 0.01% of the total mass of the silicon-based negative electrode material.

[0037] The preparation method of the silicon-based negative electrode material provided in this embodiment includes:

[0038] Dissolve 0.02 parts by mass of hexachlorocyclotriphosphazene and 100 parts by mass of silicon oxide in 200 parts by mass of toluene, fully stir with a mechanical stirrer for 4 hours and mix evenly. 10 Pa) and heated for 48 hours. After the reaction, the obtained material was washed with toluene, filtered to remove the solvent, and dried at 150° C. to obtain a silicon-based negative ele...

Embodiment 2

[0042] The silicon-based negative electrode material provided in this example includes silicon oxide and a polymer coated on the surface of silicon oxide, wherein the silicon oxide is in the form of irregular particles, and its Dv50 is 20 μm; the polymer has the structure shown in formula 1 , the average degree of polymerization n is 1000, R 1 and R 2 Both are -Cl, and the mass of the polymer is 0.11% of the total mass of the silicon-based negative electrode material.

[0043] The preparation method of the silicon-based negative electrode material and the negative electrode sheet provided in this example may refer to Example 1, except that the mass fraction of hexachlorocyclotriphosphazene is 0.21.

Embodiment 3

[0045] The silicon-based negative electrode material provided in this example includes silicon oxide and a polymer coated on the surface of silicon oxide, wherein the silicon oxide is in the form of irregular particles, and its Dv50 is 20 μm; the polymer has the structure shown in formula 1 , the average degree of polymerization n is 1000, R 1 and R 2 Both are -Cl, and the mass of the polymer is 1.31% of the total mass of the silicon-based negative electrode material.

[0046] The preparation method of the silicon-based negative electrode material and the negative electrode sheet provided in this example can refer to Example 1, except that the mass fraction of hexachlorocyclotriphosphazene is 2.01.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com