Universal electrode material for lithium-sulfur battery and preparation method thereof

A general-purpose electrode and composite material technology, applied in battery electrodes, lithium batteries, negative electrodes, etc., can solve the problems of dendrite growth, sulfur positive electrode shuttle effect, etc., and achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

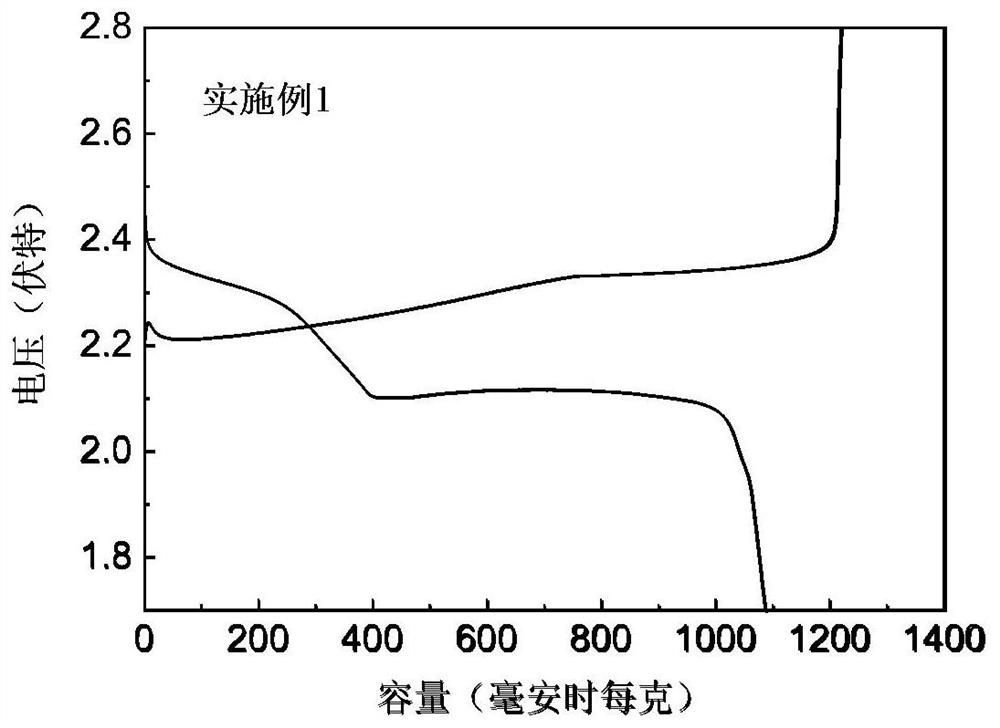

Embodiment 1

[0031] The general electrode material for lithium-sulfur batteries is a dense and highly ordered three-dimensional graphene solid composite material.

[0032] The preparation method of described universal electrode material, comprises the following steps:

[0033] (1) Preparation of graphene hydrogel: first add 21 mL of deionized water to 9 mL of graphene oxide dispersion with a concentration of 10 mg / mL, stir for 0.5 h, and dilute to a concentration of 3 mg / mL; Add 0.202 g of KOH solution with a concentration of 0.12 mol / L to the olefin dispersion, stir continuously at room temperature for 1 hour, then transfer the mixed solution to a 50 mL autoclave and heat it at 180 ° C for 6 hours. After the reactor cools down, graphite is obtained. Alkene hydrogel;

[0034] (2) Preparation of graphene solid composite material: first, the graphene hydrogel obtained in step (1) is rinsed with an aqueous hydrochloric acid solution of 1mol / L for 3 to 4 times to remove residual KOH, and then...

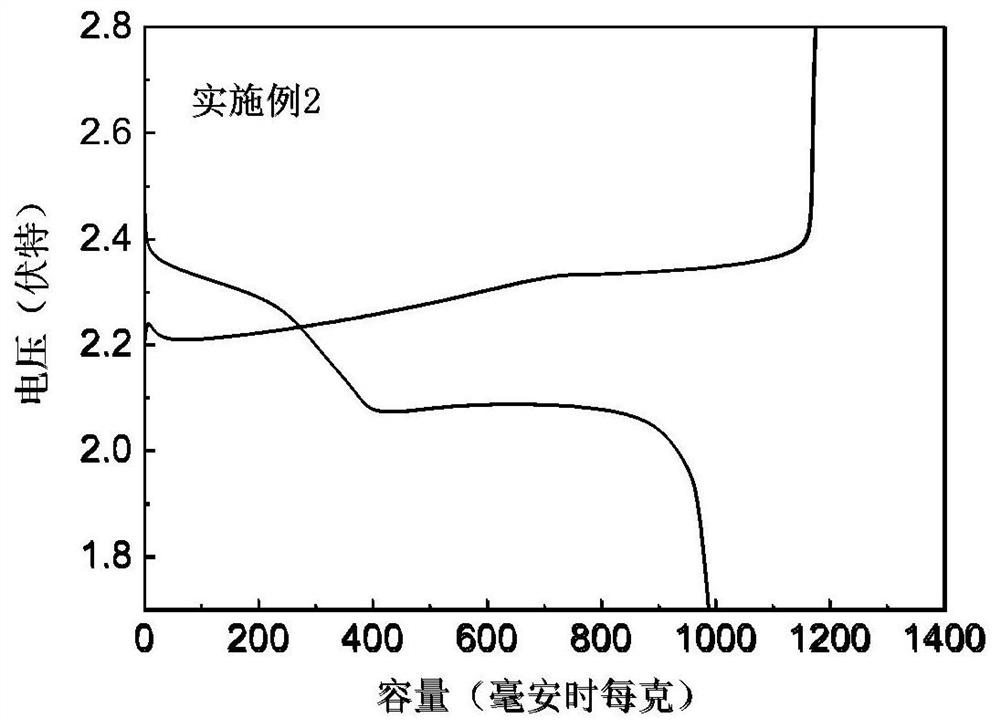

Embodiment 2

[0037] The preparation method of the general electrode material is characterized in that it comprises the following steps:

[0038] (1) Preparation of graphene hydrogel: first add 21 mL of deionized water to 9 mL of graphene oxide dispersion with a concentration of 10 mg / mL, stir for 0.5 h, and dilute to a concentration of 3 mg / mL; Add 0.168 g of KOH solution with a concentration of 0.10 mol / L to the olefin dispersion, stir continuously at room temperature for 1 hour, then transfer the mixed solution to a 50 mL autoclave and heat it at 180 ° C for 6 hours. After the reactor cools down, graphite is obtained. Alkene hydrogel;

[0039] (2) Preparation of graphene solid composite material: first, the graphene hydrogel obtained in step (1) is rinsed with an aqueous hydrochloric acid solution of 1mol / L for 3 to 4 times to remove residual KOH, and then the residual hydrochloric acid is removed by dialysis; Finally, the treated graphene hydrogel was dried in a vacuum oven at 55° C. f...

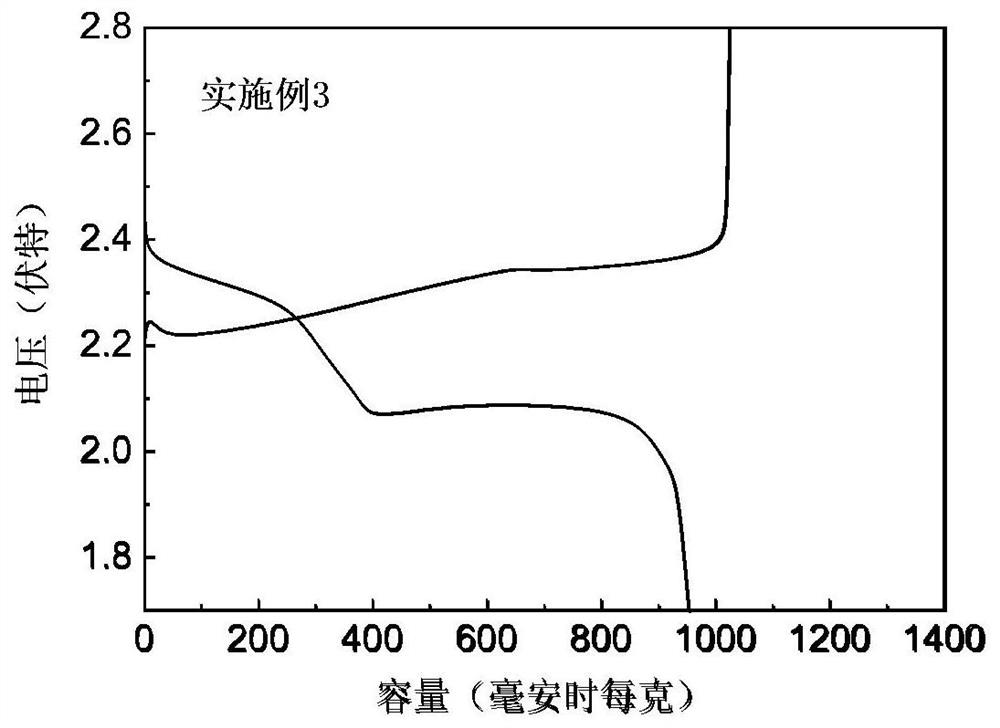

Embodiment 3

[0042] The preparation method of the general electrode material is characterized in that it comprises the following steps:

[0043] (1) Preparation of graphene hydrogel: first add 21 mL of deionized water to 9 mL of graphene oxide dispersion with a concentration of 10 mg / mL, stir for 0.5 h, and dilute to a concentration of 3 mg / mL; Add 0.252 g of KOH solution with a concentration of 0.15 mol / L to the olefin dispersion, stir continuously at room temperature for 1 hour, then transfer the mixed solution to a 50 mL autoclave and heat it at 180°C for 6 hours. After the reaction kettle cools down, graphite is obtained. Alkene hydrogel;

[0044] (2) Preparation of graphene solid composite material: first, the graphene hydrogel obtained in step (1) is rinsed with an aqueous hydrochloric acid solution of 1mol / L for 3 to 4 times to remove residual KOH, and then the residual hydrochloric acid is removed by dialysis; Finally, the treated graphene hydrogel was dried in a vacuum oven at 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com