Composition having effects of protecting livers and eyes, and preparation method and applications of composition

A technology of composition and action, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, applications, etc. It can solve the problems of toughness, viscosity, slippery feeling and poor taste, and achieve brewability Good, improve efficacy, easy to scrape off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

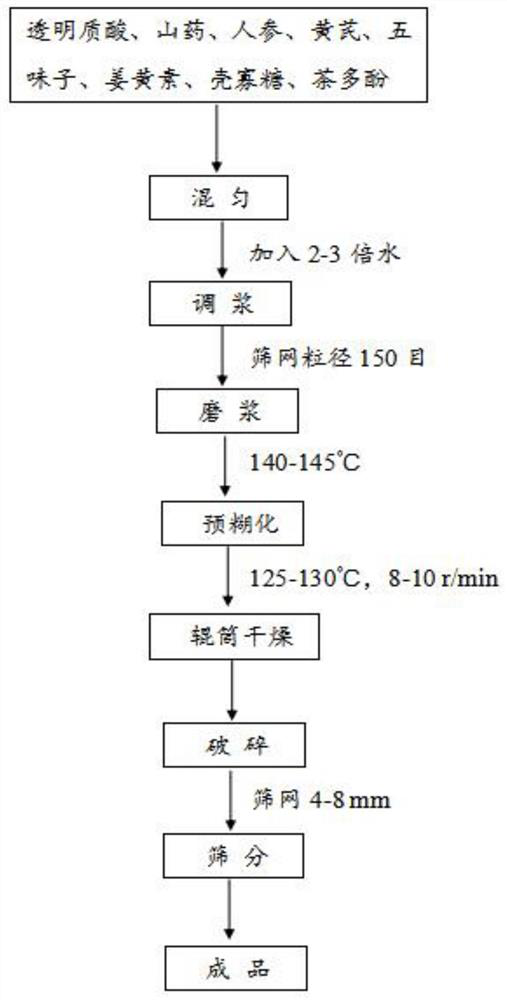

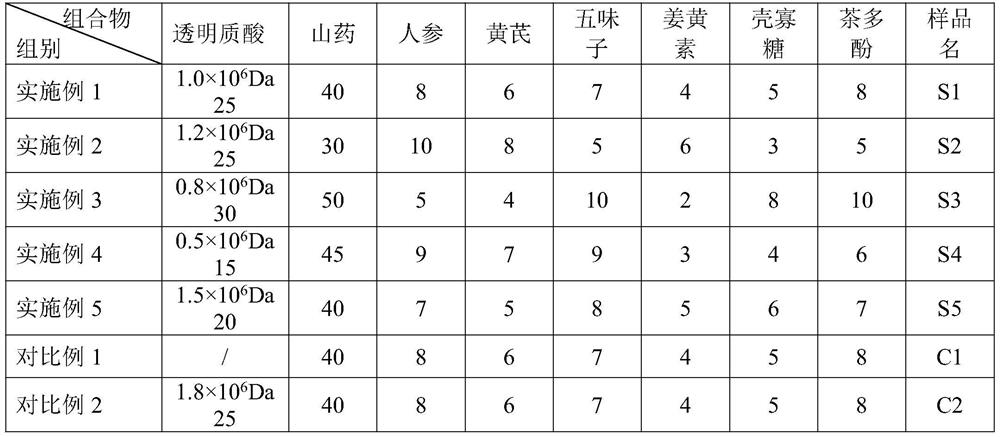

[0064] The preparation of embodiment 1 health rice noodles

[0065] Take the molecular weight as 1.0×10 6 25 parts of Da's hyaluronic acid, 40 parts of yam, 8 parts of ginseng, 6 parts of astragalus, 7 parts of schisandra, 4 parts of curcumin, 5 parts of chitosan oligosaccharide, and 8 parts of tea polyphenols. After mixing evenly, add purified water to make slurry , stir evenly, and the amount of purified water used is 2.5 times the mass of the above total materials;

[0066] The above slurry is refined through a colloid mill, and the particle size of the colloid mill screen used is 150 mesh;

[0067] The refined slurry is pregelatinized on the pregelatinization roller, and the surface temperature of the roller is kept at 140-145°C;

[0068] The pre-gelatinized material is brought into the surface of the drying roller for drying until the moisture content is not higher than 4%. The drying conditions are: the roller speed is 9r / min, and the roller surface temperature is main...

Embodiment 2

[0070] The preparation of embodiment 2 health rice noodles

[0071] Take the molecular weight as 1.2×10 6 25 parts of Da's hyaluronic acid, 30 parts of yam, 10 parts of ginseng, 8 parts of astragalus, 5 parts of schisandra, 6 parts of curcumin, 3 parts of chitosan oligosaccharide, and 5 parts of tea polyphenols. After mixing evenly, add purified water to make slurry , stir evenly, the amount of purified water used is 3 times of the above total material quality;

[0072] The above slurry is refined through a colloid mill, and the particle size of the colloid mill screen used is 150 mesh;

[0073] The refined slurry is pregelatinized on the pregelatinization roller, and the surface temperature of the roller is kept at 140-145°C;

[0074] The pre-gelatinized material is brought into the surface of the drying roller for drying until the moisture content is not higher than 4%. The drying conditions are: the rotating speed of the roller is 10r / min, and the surface temperature of t...

Embodiment 3

[0076] The preparation of embodiment 3 health-care rice noodles

[0077] Take the molecular weight as 0.8×10 6 30 parts of Da's hyaluronic acid, 50 parts of Chinese yam, 5 parts of ginseng, 4 parts of astragalus, 10 parts of schisandra, 2 parts of curcumin, 8 parts of chitosan oligosaccharide, 10 parts of tea polyphenols, mix well, add purified water to make slurry , stir evenly, and the amount of purified water used is twice the mass of the above total materials;

[0078] The above slurry is refined through a colloid mill, and the particle size of the colloid mill screen used is 150 mesh;

[0079] The refined slurry is pregelatinized on the pregelatinization roller, and the surface temperature of the roller is kept at 140-145°C;

[0080] The pre-gelatinized material is brought into the surface of the drying roller for drying until the moisture content is not higher than 4%. The drying conditions are: the rotating speed of the roller is 8r / min, and the surface temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com