Traditional Chinese medicine extract and preparation process and application thereof

A technology of extracts and traditional Chinese medicines, which is applied in the field of traditional Chinese medicine extracts, can solve problems such as restrictions on daily use and industrial production, reduced utilization of raw materials, and limited single extraction volume, so as to improve dissolution efficiency and dissolution rate, and improve utilization rate , Conducive to the effect of product cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

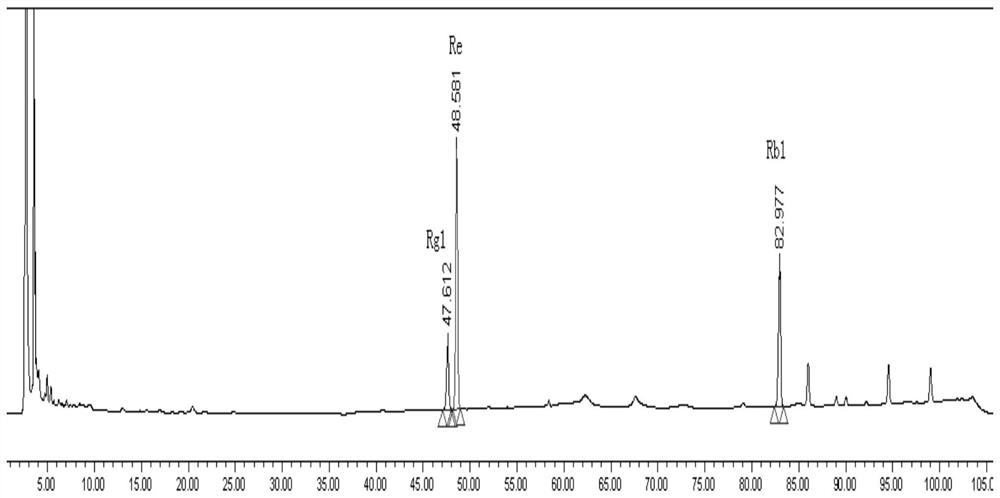

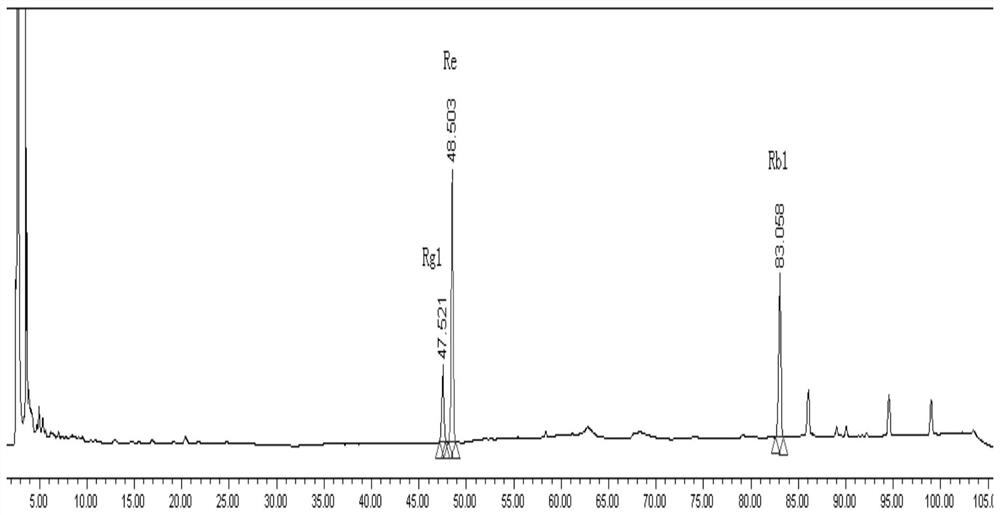

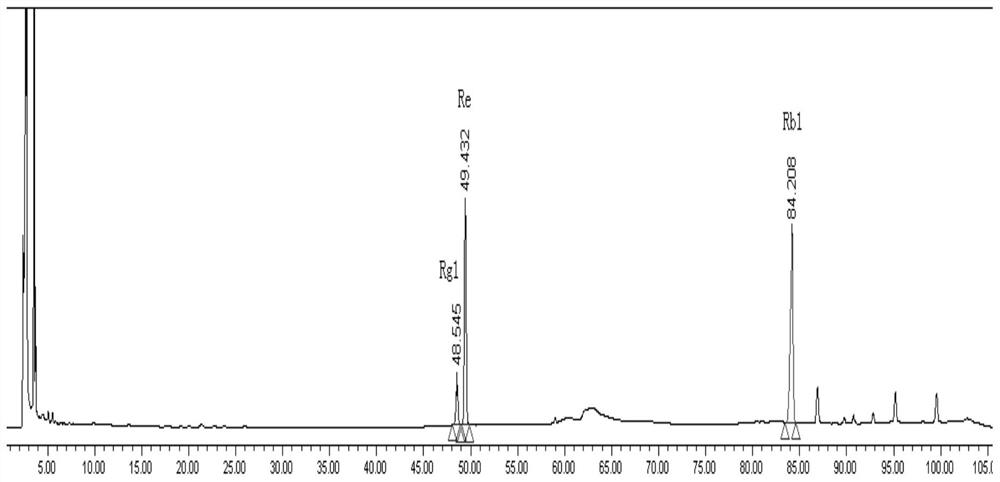

Image

Examples

preparation example Construction

[0074] In one embodiment, the preparation method includes the following steps:

[0075] Step 1: select the above raw materials and mix them;

[0076] Step 2: pulverizing the bulk drug mixed in step 1 into fine powder;

[0077] Step 3: Add the micropowder obtained in Step 2 to auxiliary materials and mix, and perform ultrasonic wall-breaking extraction to obtain an extract;

[0078] Step 4: centrifuging the extract obtained in step 3 to obtain a filtrate;

[0079] Step 5: Freezing and concentrating the filtrate obtained in Step 4 to obtain a concentrated solution, which is then made into the traditional Chinese medicine extract;

[0080] In one embodiment, the extraction solvent for the extraction is an extraction solvent commonly used in the art, such as water, ethanol, etc., and pure water is preferably used for extraction.

[0081] In one embodiment, in the step 3, the auxiliary material is cyclodextrin, preferably, the auxiliary material is selected from one or more of γ...

Embodiment 1

[0119] Example 1: The preparation method of the disclosed Chinese medicine extract and the prepared oral liquid

[0120] Choose 352 parts by weight of Ginseng, 689 parts by weight of Radix Astragali, 125 parts by weight of Radix Glycyrrhizae, 60 parts by weight of Cinnamon, and 150 parts by weight of Ginger, mix and pulverize to obtain micropowder;

[0121] The above-mentioned fine powder is obtained through secondary crushing, the secondary crushing includes the first crushing and the second crushing, the particle size of the finished product of the first crushing is 5-10 mm, and the particle size of the finished product of the second crushing is below 100 μm;

[0122] After mixing hydroxypropyl-β-cyclodextrin into the above-mentioned fine powder, use an ultrasonic extractor to perform ultrasonic wall-breaking extraction, the sound field frequency is 20kHz, and the sound intensity is 2.55W / cm 2 , The ratio of solid to liquid is 1:12, and the extraction time is 1h to obtain th...

Embodiment 2

[0127] Example 2: The preparation method of the disclosed Chinese medicine extract and the prepared oral liquid

[0128] Choose 375 parts by weight of ginseng, 700 parts by weight of astragalus, 108 parts by weight of licorice, 80 parts by weight of cinnamon, and 120 parts by weight of ginger, mix and pulverize to obtain micropowder;

[0129] The above micropowder is obtained through three times of pulverization, and the particle size of the finished product after the third pulverization is below 100 μm;

[0130] After mixing hydroxypropyl-β-cyclodextrin into the above-mentioned micropowder, use an ultrasonic extractor to perform ultrasonic wall-breaking extraction, the sound field frequency is 25kHz, and the sound intensity is 2.55W / cm 2 1. The ratio of solid to liquid is 1:10, and the extraction time is 1h to obtain the extract, the amount of hydroxypropyl-β-cyclodextrin is 1.5% of the micropowder, and the extraction solvent is purified water;

[0131] The above extract was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com