Carbon fiber-containing paper cone for loudspeaker and preparation method thereof

A loudspeaker and carbon fiber technology, applied in the direction of fiber diaphragm, synthetic cellulose/non-cellulose material pulp/paper, non-fiber pulp addition, etc., can solve the problem of inability to produce caliber, hidden danger of speaker cone delamination, weak binding force, etc. problems, to achieve strong filling effect, improve mechanical properties, and improve bulk thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

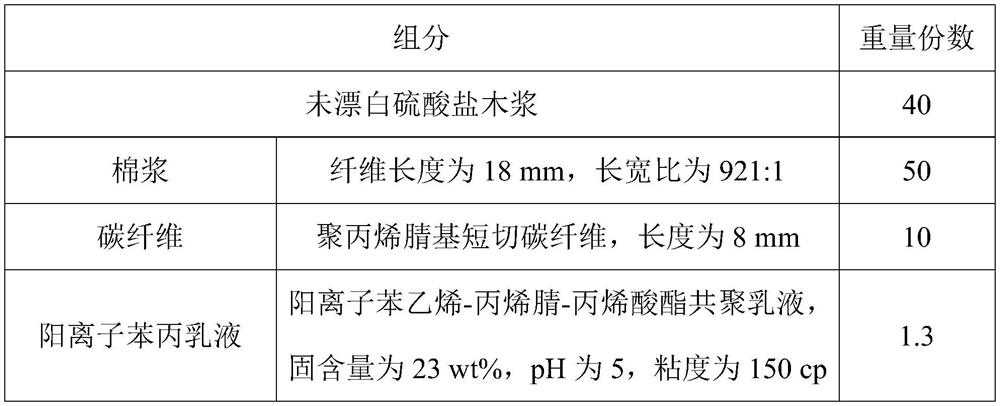

[0054] This embodiment provides a paper cone for a speaker containing carbon fiber. The raw materials for the preparation of the paper cone for a speaker containing carbon fiber include the following components in parts by weight:

[0055]

[0056] The preparation method of the described carbon fiber-containing loudspeaker cone comprises the following steps:

[0057] (1) Mix and beat unbleached kraft wood pulp and cotton pulp to obtain component A with a knockdown degree of 35°SR; dilute the cationic styrene-acrylic emulsion with 10 times of water, mix it with carbon fiber, and disperse it at 2000rpm for 40min, Get component B;

[0058] (2) After mixing component A and component B obtained in step (1), add water to dilute, the amount of water added is 10 times the total mass of component A and component B, filter to obtain paper Basin embryo;

[0059] (3) placing the paper cone blank obtained in step (2) in a high-temperature mold, pressing, and drying at 120° C. to obtai...

Embodiment 2

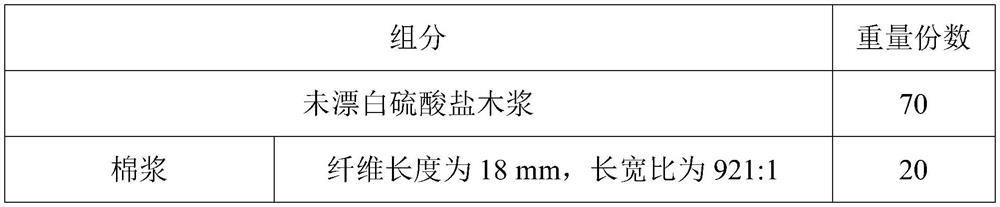

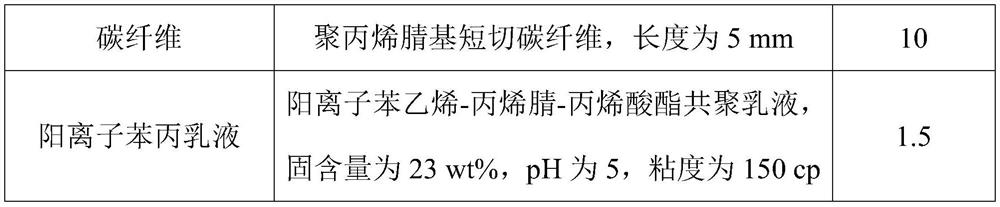

[0062] This embodiment provides a paper cone for a speaker containing carbon fiber. The raw materials for the preparation of the paper cone for a speaker containing carbon fiber include the following components in parts by weight:

[0063]

[0064]

[0065] The preparation method of the described carbon fiber-containing loudspeaker cone comprises the following steps:

[0066] (1) Mix and beat unbleached kraft wood pulp and cotton pulp to obtain component A with a knockdown degree of 30°SR; dilute the cationic styrene-acrylic emulsion with 10 times of water, mix it with carbon fiber, and disperse it at 2000rpm for 40min, Get component B;

[0067] (2) After mixing component A and component B obtained in step (1), add water to dilute, the amount of water added is 10 times the total mass of component A and component B, filter to obtain paper Basin embryo;

[0068] (3) placing the paper cone blank obtained in step (2) in a high-temperature mold, pressing, and drying at 130°...

Embodiment 3

[0071] This embodiment provides a paper cone for a speaker containing carbon fiber. The raw materials for the preparation of the paper cone for a speaker containing carbon fiber include the following components in parts by weight:

[0072]

[0073] The preparation method of the described carbon fiber-containing loudspeaker cone comprises the following steps:

[0074] (1) Mix and beat unbleached kraft wood pulp and cotton pulp to obtain component A with a knockdown degree of 25°SR; dilute the cationic styrene-acrylic emulsion with 10 times of water, mix it with carbon fiber, and disperse it at 2000rpm for 40min, Get component B;

[0075] (2) After mixing component A and component B obtained in step (1), add water to dilute, the amount of water added is 10 times the total mass of component A and component B, filter to obtain paper Basin embryo;

[0076] (3) placing the paper cone blank obtained in step (2) in a high-temperature mold, pressing, and drying at 140° C. to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com