High-activity and high-stability PtNi nano-alloy catalyst as well as preparation method and application thereof

A nano-alloy, catalyst technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of catalyst activity loss, poor stability, etc., to reduce Pt loading, improve stability, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a kind of preparation method of PtNi nano-alloy material, comprises the following steps:

[0067] a) After dispersing the platinum source, the nickel source and the solvent, a dispersion liquid is obtained;

[0068] b) Under airtight conditions, after reacting the dispersion liquid obtained in the above steps, a reaction product is obtained;

[0069] c) After post-processing the reaction product obtained in the above steps, an intermediate is obtained;

[0070] d) Under a protective atmosphere, heat-treat the intermediate obtained in the above steps to obtain a PtNi nano-alloy material.

[0071] The selection, proportioning and process parameters of the materials in the steps of the above-mentioned PtNi nano-alloy materials of the present invention, and the corresponding optimization principles, and the selection, proportioning and process parameters of the materials in the follow-up PtNi nano-alloy catalyst preparation method, and c...

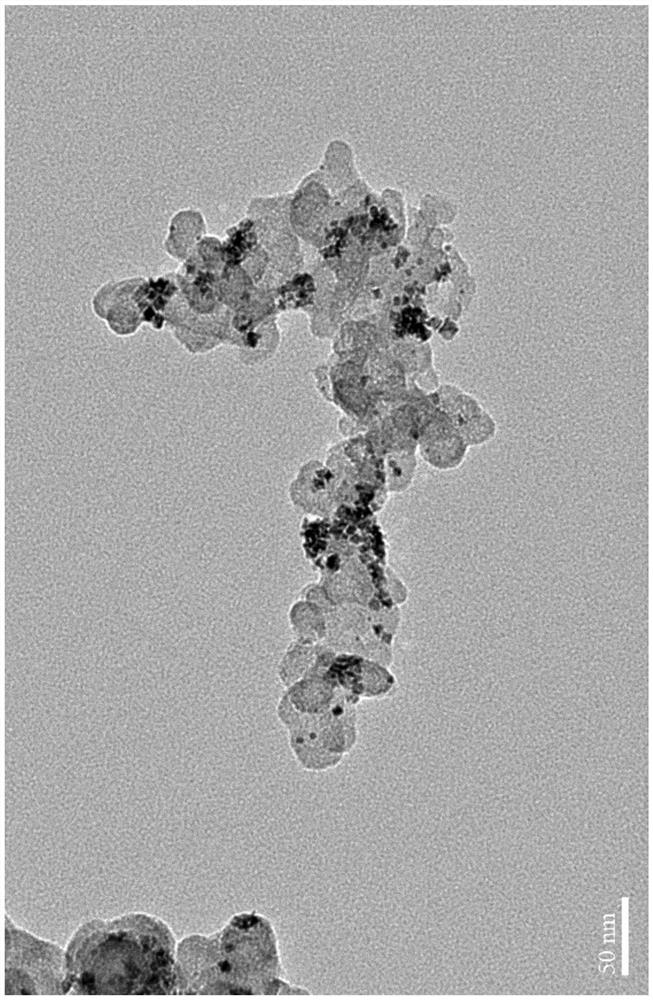

Embodiment 1

[0122] (1) In a 20mL reactor, weigh 40mg of platinum (II) acetylacetonate (Pt(acac) 2 ), 65mg nickel (II) acetylacetonate (Ni(acac) 2 ) and 40mg of Vulcan X72 carbon carrier, dispersed in 5mL N, N-dimethylformamide (DMF) under ultrasonic conditions;

[0123] (2) Maintain ultrasound for 50 minutes on the above-mentioned mixed precursor solution;

[0124] (3) Seal the above reaction kettle and place it in an oven, set the temperature at 120°C, and heat for 40h;

[0125] (4) After natural cooling, the product in the reactor was collected by centrifugation at 11000r / min for 8min;

[0126] (5) Add a water-ethanol mixture with a volume ratio of 1:1 (volume ratio 1:1) into the centrifuge tube containing the sample after centrifugation, and disperse and clean it by ultrasonication for 15 minutes. Centrifuge again at 11000r / min for 8min, repeat this step 3 times;

[0127] (6) The final product in step (5) was collected by centrifugation and vacuum-dried at 60° C. for 3 h;

[0128]...

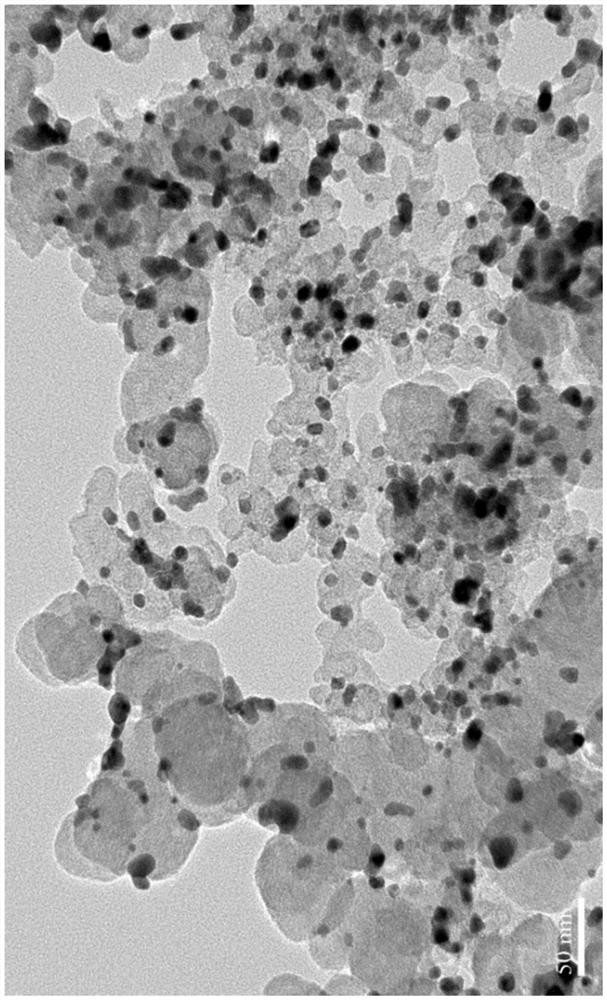

Embodiment 2

[0152] (1) In a 25mL flask, weigh 40mg of platinum(II) acetylacetonate (Pt(acac) 2 ), 65mg nickel (II) acetylacetonate (Ni(acac) 2 ), dispersed in 5mL ethylene glycol under ultrasonic conditions, and another beaker was used to disperse 40mg of nitrogen-doped graphene ultrasonically in 5mL ethylene glycol;

[0153] (2) Keep ultrasound for 20min to the above-mentioned mixed precursor solution and graphene suspension;

[0154] (3) Use a magnetic stirrer to stir and mix the precursor solution, and simultaneously add the nitrogen-doped graphene suspension after ultrasonication dropwise to the mixed precursor solution under stirring;

[0155] (4) Heating in an oil bath, set the temperature at 160°C, and heat for 48 hours;

[0156] (5) After natural cooling, the product in the beaker was collected by centrifugation at 11000r / min for 8min;

[0157] (6) Add a water-ethanol mixture with a volume ratio of 1:1 (volume ratio 1:1) into the centrifuge tube containing the sample after cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com