Pd/HNC catalytic material, preparation method thereof and application of Pd/HNC catalytic material as fuel cell catalyst

A catalytic material and carbonization treatment technology, applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve problems such as poor stability, achieve good stability, convenient preparation, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Shewanella culture

[0041] A single colony of Shewanella oneidensis MR-1 was selected and inoculated in 50 mL of sterilized Luria-Bertani medium (5 g of yeast extract, 5 g of NaCl, and 10 g of tryptone per liter of medium) for culture. Shake the shaker at 170 rpm at 30°C for 12 h.

[0042] 2. Adsorption of palladium ions by Shewanella

[0043]Take 4L of sterilized LB culture solution, add 0.08L of activated bacteria (inoculum size 2%), shake at 170rpm at 30°C for 20h, (OD600 about 1.5); then centrifuge at 12000rmp for 7min to collect bacteria, pour The supernatant and the precipitate were washed twice with phosphate buffer solution and sterile water respectively, and the precipitate was weighed (about 47.5g). The washed Shewanella cells were redissolved (sonicated for 0.5h) in an appropriate amount of deionized water and Add an appropriate amount of dilute hydrochloric acid to adjust the pH to 4 for later use; 150mL 1000mg / L Pd 2+ The solution was slowly dripped ...

Embodiment 2

[0055] Change the heat treatment to: firstly pass air from room temperature to 200°C for 1 hour; keep warm at 200°C for 2 hours to partially carbonize and activate the bacterial cells; pass Ar from 200°C to 700°C for 1 hour; hold at 700°C for 2 hours to completely carbonize the bacteria . Other processing conditions are all identical with embodiment 1.

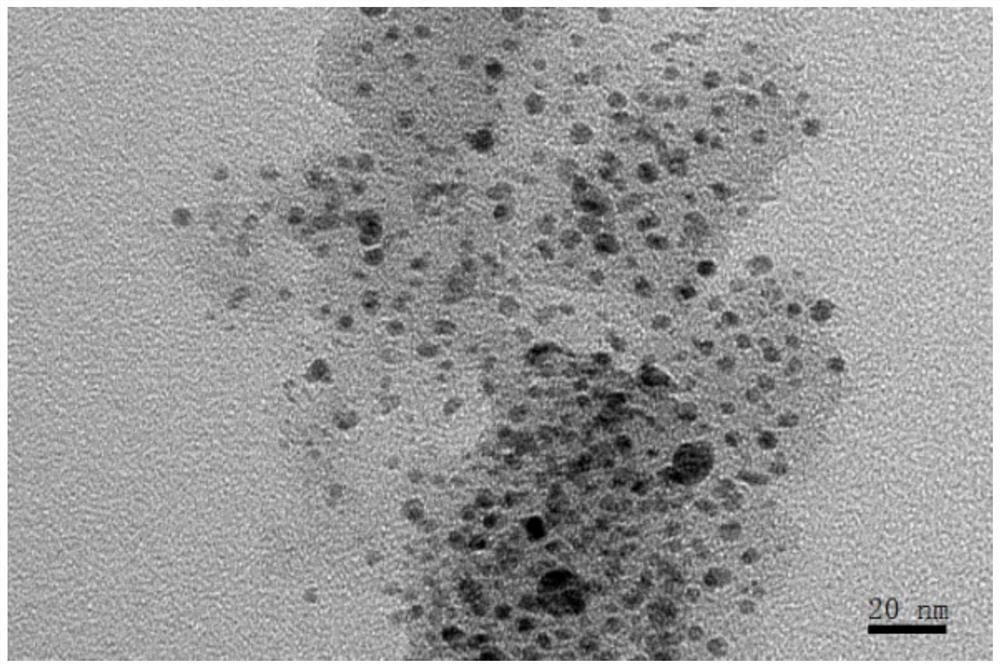

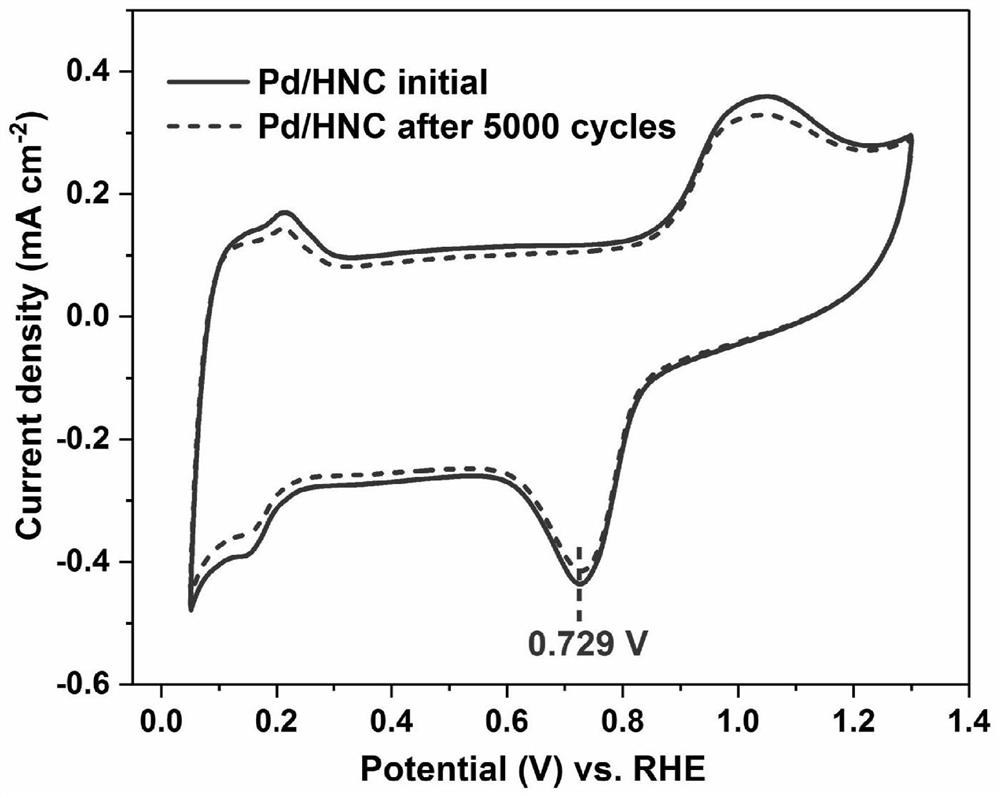

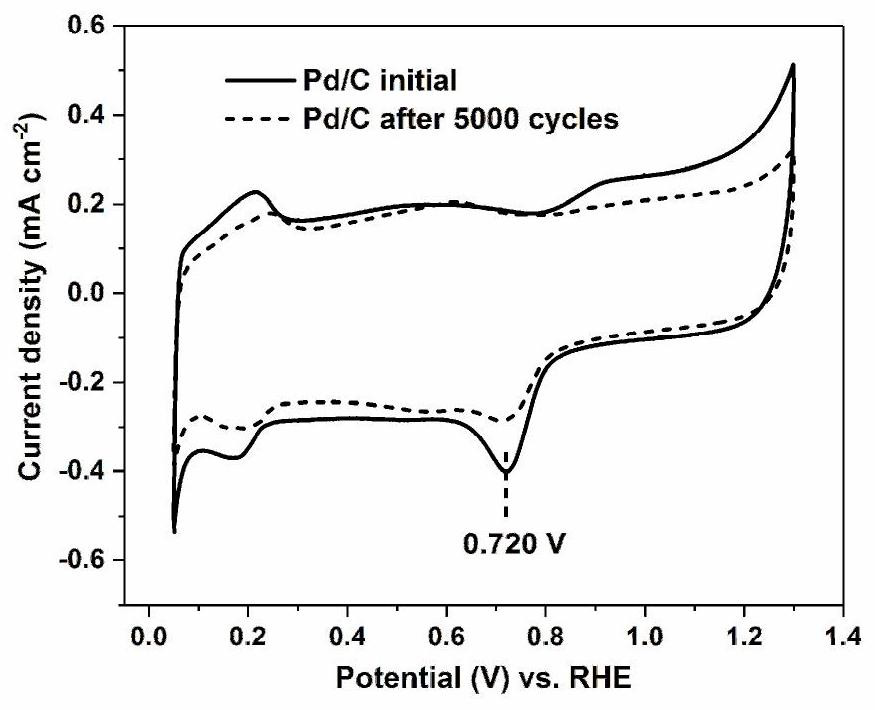

[0056] After carbonization treatment at 700°C, the particle size of the catalyst particles ranges from 3 to 8nm, and the conductivity of the bacterial carbon is improved. The mass specific activity of the carbonized bacteria-supported palladium catalyst obtained at this carbonization temperature in acidic medium is 0.276mA / μg is 1.06 times that obtained by carbonization treatment at 600°C; after 5000 cycle stability tests, the mass specific activity decreased by 10.2%, and the stability is also higher than that obtained by carbonization at 600°C. That is, the activity and stability of the carbonized bacteria-supported pallad...

Embodiment 3

[0058] Change the heat treatment to: firstly, the air is raised from room temperature to 200°C for 1 hour; the temperature is kept at 200°C for 2 hours to partially carbonize and activate the bacterial cells; the Ar is raised from 200°C to 800°C for 1.5 hours; the temperature is kept at 800°C for 2 hours to completely carbonization. Other processing conditions are all identical with embodiment 1.

[0059] After carbonization treatment at 800°C, the particle size of the catalyst particles ranges from 3 to 10 nm, and the conductivity of the bacterial carbon is further improved. The mass specific activity of the carbonized bacteria-supported palladium catalyst obtained at this carbonization temperature in acidic medium is 0.339mA / μg, which is 1.3 times that obtained by carbonization at 600°C; after 5000 cycle stability tests, the mass specific activity has decreased by 8.1%, and the stability is also higher than that obtained by carbonization at 600°C. That is, the activity and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com