Conductive material, electrode including same, secondary battery including same, and method for producing same

一种导电材料、石墨烯片的技术,应用在二次电池、电池电极、非水电解质蓄电池等方向,能够解决导电性改善不足、增加生产成本、电极电阻增加等问题,达到改善电池容量、消除结构应力、低粉末电阻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

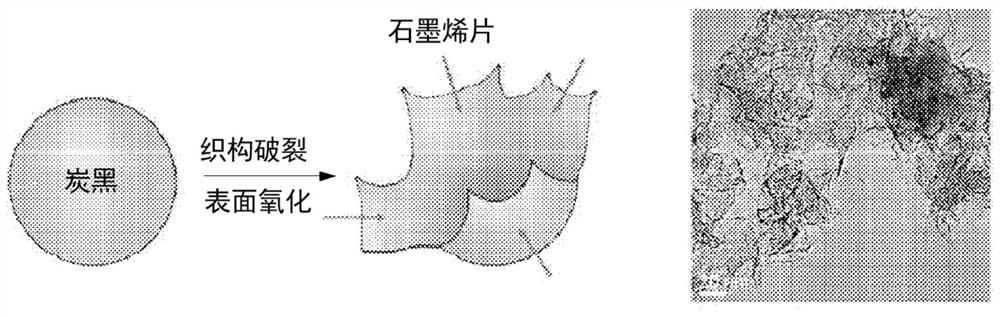

[0062] A method for preparing a conductive material according to still another exemplary embodiment of the present invention includes: a method for preparing a conductive material, the method including: a step of preparing a preliminary conductive material; and a step of converting the preliminary conductive material by oxidation treatment , wherein the step of transforming the preliminary conductive material through oxidation treatment comprises at least one of the following: a) heat-treating the preliminary conductive material at a temperature of 200°C to 800°C in an oxygen atmosphere or an air atmosphere; and b) at The preliminary conductive material is reacted with acid vapor at 120°C to 300°C.

[0063] In the step of preparing the preliminary conductive material, the preliminary conductive material may be carbon black. Specifically, the preliminary conductive material may be at least one selected from the group consisting of acetylene black, furnace black, thermal black, ...

Embodiment 1

[0075] Embodiment 1: Preparation of conductive material

[0076] (1) Formation of preliminary conductive material (acetylene black)

[0077] Acetylene gas with a purity of 98% is instantaneously sprayed onto a reactor with an internal temperature of 2,000°C and pyrolyzed to form acetylene black.

[0078] (2) Preparation of conductive materials

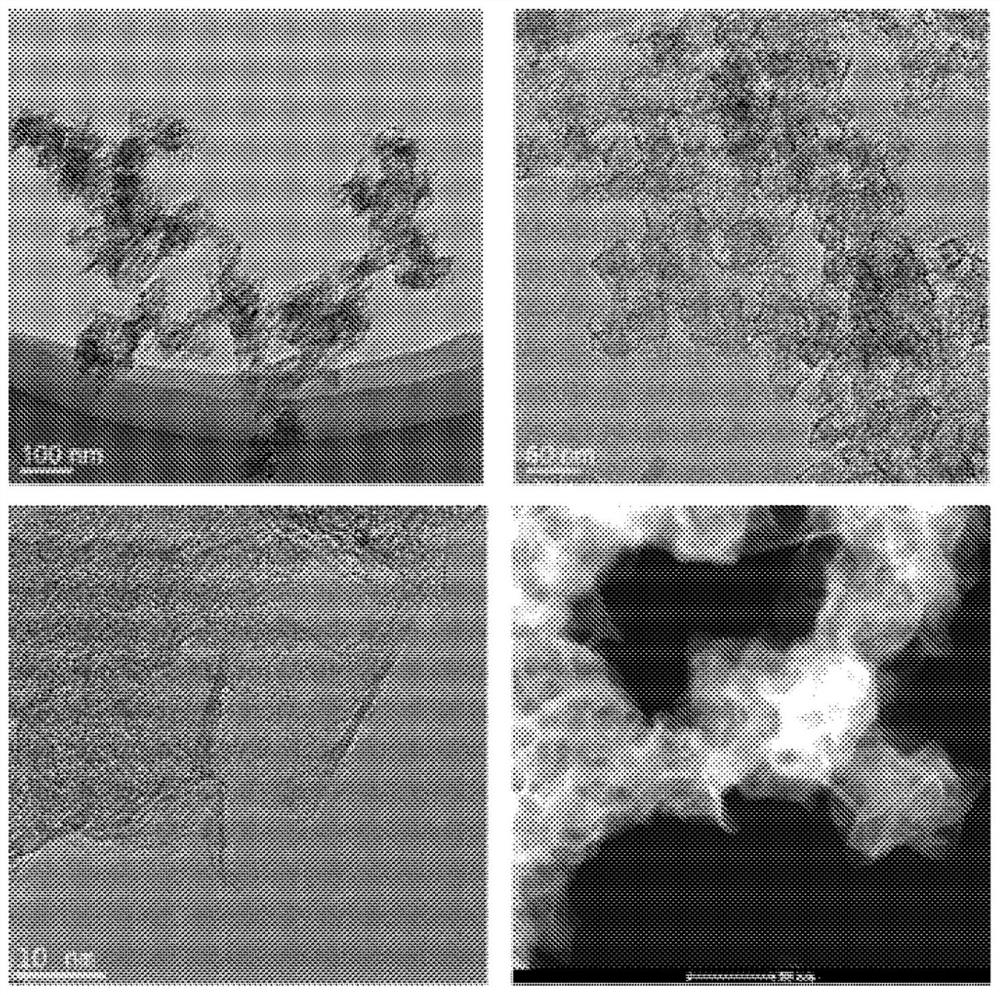

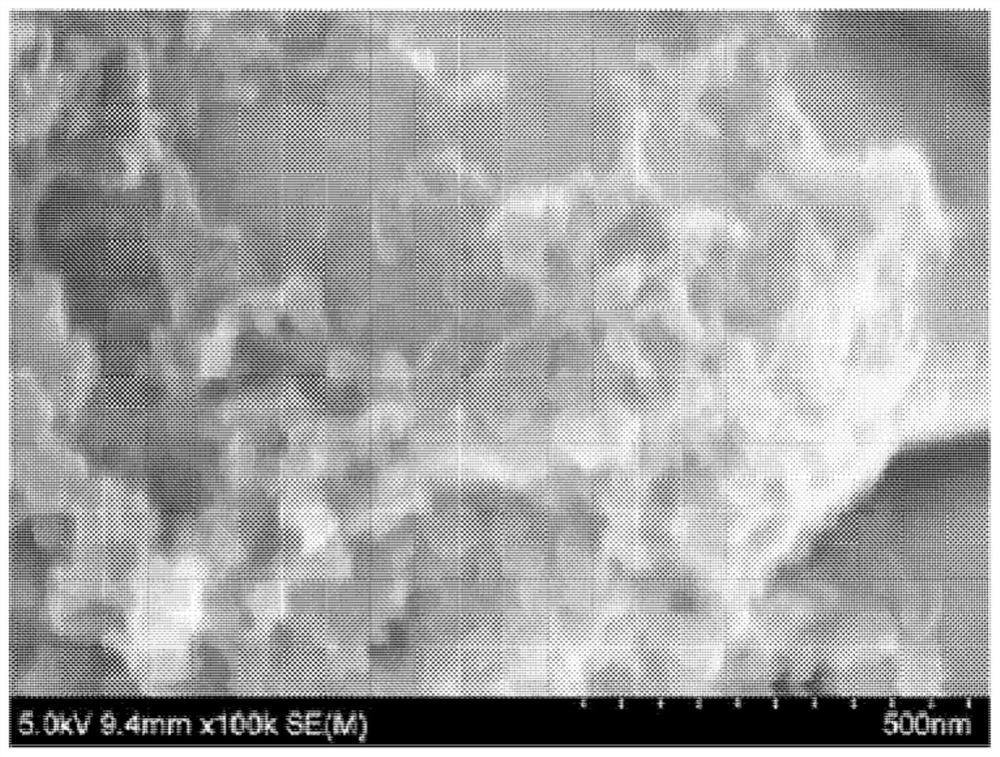

[0079] Subsequently, the internal temperature of the reactor containing acetylene black was set to 250° C., and then an oxidation treatment was performed for 30 hours while introducing oxygen gas thereinto. As a result, a conductive material with a secondary grain structure was obtained in which a plurality of graphene sheets interconnected with a lateral size (lateral size) of 40 nm (see figure 2 and image 3 ).

Embodiment 2

[0080] Embodiment 2: Preparation of conductive material

[0081]For the conductive material obtained in Example 1, a further heat treatment was carried out at 900° C. for 1 hour in an inert atmosphere to obtain a conductive material with a secondary granular structure, wherein a plurality of graphene sheets with a lateral size of 65 nm interconnection. refer to Figure 4 , it can be confirmed that Figure 4 The conductive material of Example 1 shown in (a) is transformed into Figure 4 (b) The conductive material of Example 2 shown. Specifically, it was confirmed that graphene sheets adjacent to each other were interconnected by heat treatment and increased in lateral size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com