Degradable composite absorption core, preparation method thereof and application thereof in paper diapers

A technology of absorbent core and composite polylactic acid, which is applied in the fields of application, absorbent pad, medical science, etc., can solve the problems of low degradability of diapers and unrealizable degradation design of absorbent core, and achieve good skin-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

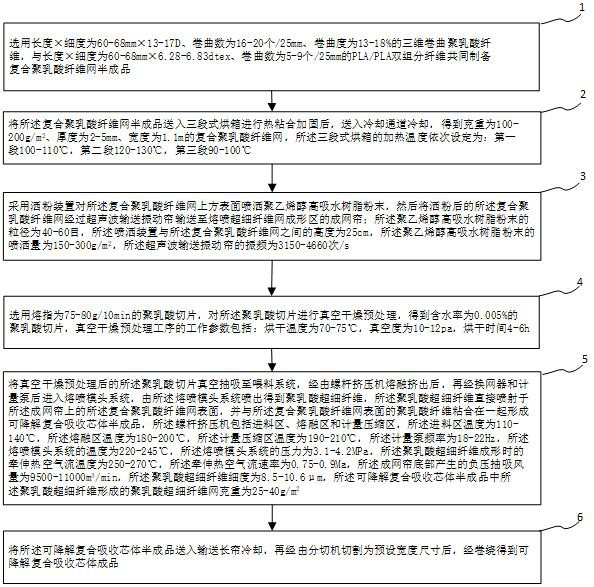

[0034] figure 1 It is a method flowchart of a method for preparing a degradable composite absorbent core shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of this degradable composite absorbent core comprises:

[0035] Step (1): Choose a three-dimensional crimped polylactic acid fiber with a length × fineness of 60-68mm × 13-17D, a number of crimps of 16-20 pieces / 25mm, and a crimp of 13-18%, and a length × fineness of 60 -68mm×6.28-6.83dtex, PLA / PLA bicomponent fibers with a crimp number of 5-9 pieces / 25mm are used to prepare a semi-finished composite polylactic acid fiber web.

[0036] Preferably, the preparation method of the semi-finished composite polylactic acid fiber web comprises:

[0037] (a) After the three-dimensional crimped polylactic acid fiber and the PLA / PLA bicomponent fiber were subjected to hydrophilic softening treatment by spraying method, they were left to stand at room temperature for 24 hours to make the three-...

Embodiment 1

[0054] Step (1): Choose a three-dimensional crimped polylactic acid fiber with a length×fineness of 60mm×13D, a number of crimps of 16 pieces / 25mm, and a crimp of 13%, and a length×fineness of 60mm×6.28dtex, and a number of crimps of 5 The PLA / PLA two-component fiber of each 25mm prepares composite polylactic acid fiber web semi-finished product jointly, and the preparation method of described composite polylactic acid fiber web semi-finished product comprises:

[0055](a) After the three-dimensional crimped polylactic acid fiber and the PLA / PLA bicomponent fiber were subjected to hydrophilic softening treatment by spraying method, they were left to stand at room temperature for 24 hours to make the three-dimensional crimped polylactic acid fiber and the PLA / PLA bicomponent fiber The content of the hydrophilic softening oil agent on the surface of the PLA / PLA two-component fiber is 1-2.2%, and the mass ratio of each component of the hydrophilic softening oil agent is hydrophili...

Embodiment 2

[0069] Step (1): Choose a three-dimensional crimped polylactic acid fiber with a length×fineness of 64mm×13-17D, a number of crimps of 18 pieces / 25mm, and a crimp of 15%, and a length×fineness of 64mm×6.67dtex, a number of crimps For the PLA / PLA two-component fiber of 7 / 25mm prepares composite polylactic acid fiber web semi-finished product jointly, the preparation method of described composite polylactic acid fiber web semi-finished product comprises:

[0070] (a) After the three-dimensional crimped polylactic acid fiber and the PLA / PLA bicomponent fiber were subjected to hydrophilic softening treatment by spraying method, they were left to stand at room temperature for 24 hours to make the three-dimensional crimped polylactic acid fiber and the PLA / PLA bicomponent fiber The content of the hydrophilic softening oil agent on the surface of the PLA / PLA two-component fiber is 2.3-3.5%, and the mass ratio of each component of the hydrophilic softening oil agent is hydrophilic agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number of curls | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com