Anti-clogging and screening machine for compound fertilizer production

A screening machine and compound fertilizer technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problem of inability to achieve continuous, efficient, high-quality production, inability to achieve continuous production, and high production time and energy consumption. problems, to ensure the production environment is friendly, the fertilizer release effect is good, and the loss of raw materials is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

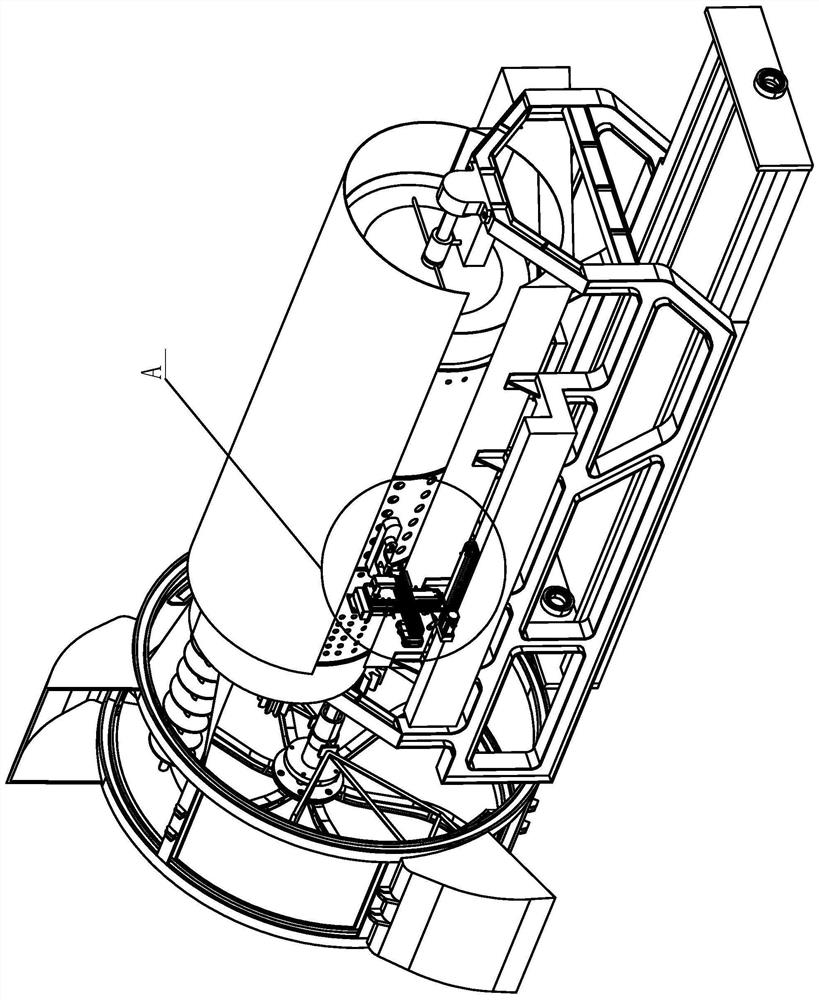

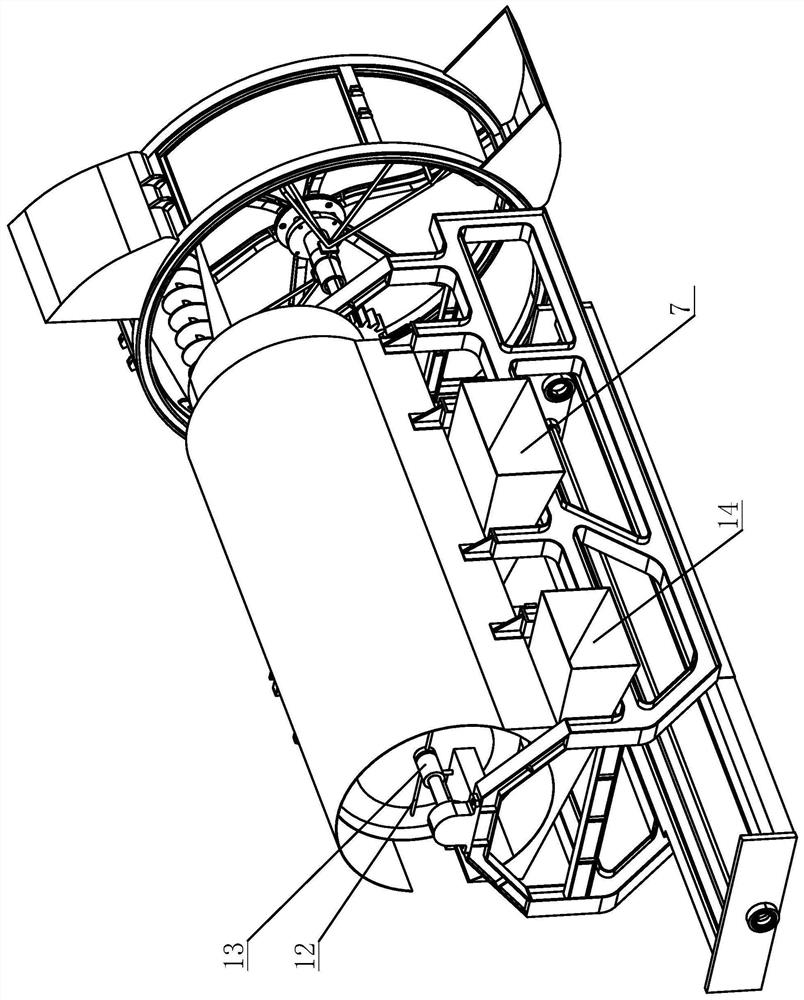

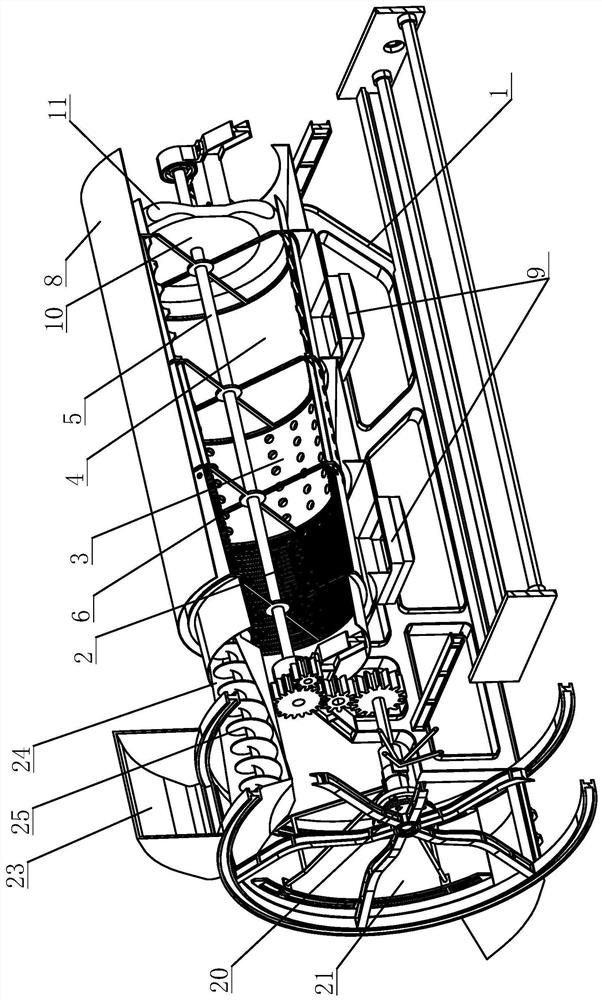

[0041] Embodiment 1: A kind of anti-clogging screening machine for compound fertilizer production

[0042] The screening machine designed in this example breaks the existing thinking limitations of using multi-layer disc vibrating screens, and adopts the basic design idea of the drum to screen, recycle, receive, feed, dust-proof, and strengthen dehumidification of particles. All aspects have been improved and considered in an all-round way. The specific structure is as follows:

[0043] Including machine base 1, screening mechanism, feeding mechanism, and blockage cleaning mechanism;

[0044] 1) Base 1

[0045] The base 1 is used to be fixed on the bottom surface of the workshop, or on the base in the workshop, to support the whole screening machine. The screening mechanism, the feeding mechanism and the discharging mechanism are all installed on the machine base 1 . Machine base 1 adopts steel frame to support the whole.

[0046] 2) Screening mechanism

[0047]The scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com